Home » 3D Printing Materials » Jet Fusion Technology for 3D Printing » Jet Fusion PA12

Multi Jet Fusion PA 12 3D printing material

This plastic 3D printing material developed by HP has great properties for your prototyping or production processes. You will find here all information, tricks, know-how, and advice to help you print your 3D model in our Multi Jet Fusion PA 12 (plastic) material.

Colors

Finishes

Characteristics

Multi Jet Fusion PA12 Material Guide

What is MultiJet Fusion PA 12 ?

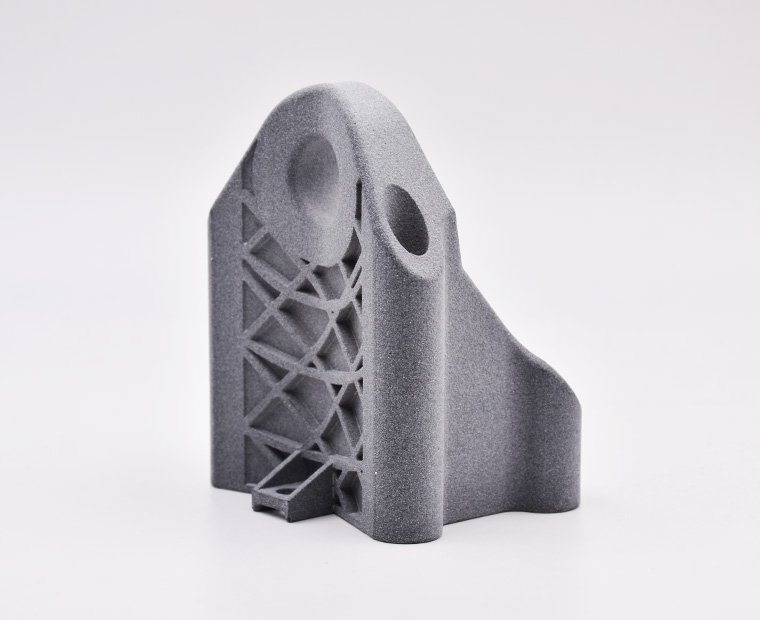

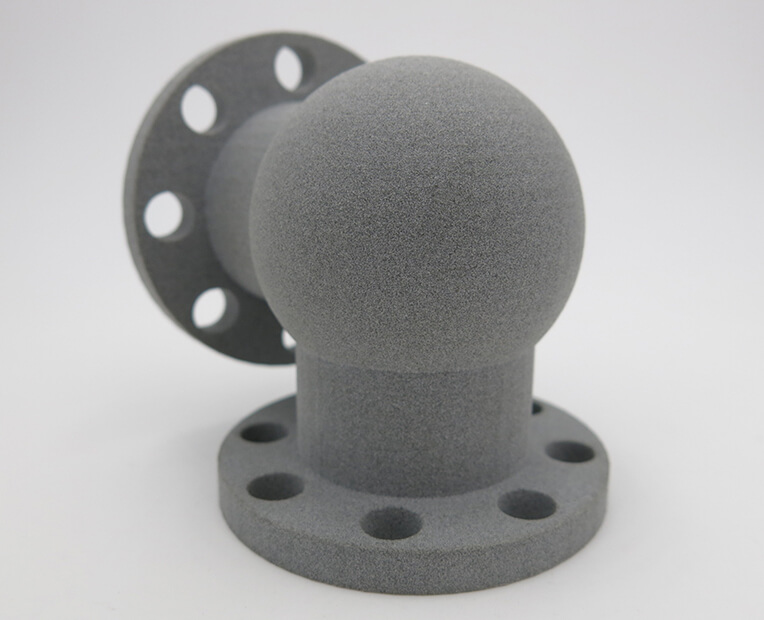

The Multijet Fusion PA12 (or MJF PA12) objects printed through Sculpteo are created from a fine polyamide powder. The material is characterized by good elasticity and high impact resistance. Moreover, polyamide has excellent resistance to chemicals, especially hydrocarbons, aldehydes, ketones, mineral bases and salts, alcohols, fuels, detergents, oils, and fats. HP plastic is great for both experienced professionals and beginning designers because of its high precision. Indeed, 3D printing plastic appears to be a good substitute to plastic injection for product development, rapid prototyping, and even production process.

The 3D printed objects printed with this plastic material are well suited against scratches and abrasion. This material is also light stabilized, U.V. stabilized and stable to weather.

Mulitjet Fusion PA12 3D printing material is biocompatible. Coming out of the printer: parts are grey, this is the ‘non-dyed’ option, which is a more economical option for you to choose from compared to all our other materials.

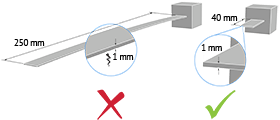

Technical properties of the Multijet Fusion PA12 change depending on the thickness of your model. Please check our blog post on elastic modulus measurements for more information on flexibility. Keep in mind that you will have to respect the minimum wall thickness of the material to avoid any problem during the additive manufacturing process. Be sure to check the material design guidelines while creating your 3D file.

All information related to tensile modulus, chemical resistance or heat deflection temperature for this HP material is available in the technical section of this material page.

Your Multijet Fusion PA12 part is made from a reusable polyamide powder material: that is why this material can sometimes be called HP High Reusability PA12.

What are the possible applications for this material?

Our Multijet Fusion PA12 has great mechanical properties. Indeed, this HP material offers versatility when 3D printing, especially complex models, as it is flexible, offers high impact resistance, is light stabilized, and is stable to every weather. As a result, the objects in this material have a wide range of uses from mechanical (prototypes, geared systems, articulated objects, etc.), electrical, medical, ornamental, or even educational purposes. In the automotive industry, it is mainly used for interior components for crash-relevant parts. From functional prototyping to production, these material properties offer a lot of opportunities.

In terms of temperature, if the plastic is subjected to heat above 187°C (369°F), it is possible that the physical form of the object can be significantly altered.

Technical properties of the Multijet Fusion PA12 change depending on the thickness of your model. Please check our blog post on elastic modulus measurements for more information on flexibility.

Pricing

The printing price of your design is calculated automatically the moment it is uploaded. As you modify your object (changing material, finishing, size, using batch control or hollowing feature, etc.) you will note that the price changes automatically. The pricing is based on a series of factors, including total volume, object size, and bounding box – to name a few.

Keep in mind that adding finishing will extend the processing time. The estimated shipping time is also calculated automatically as the object is uploaded and each time you make a modification on it. Delivery time should be added to processing time.

For more information, check our pricing page.

How does HP 3D printing technology work?

The Multi Jet Fusion technology’s process is similar to binder jetting technology as it uses a liquid binding agent to create the layers of your object. In addition, a detailing agent is used to obtain fine details and to smooth the surface of the object. Layer by layer, the object is created from the combination of the powder, the liquid agents (fusing and detailing agents) and the energy (heating process).

The HP Multi Jet Fusion process is a powder-bed technology that is faster than Selective Laser Sintering. After the parts are 3D printed, the building platform is placed into the post-processing station that cools the parts and prepares them for cleaning.

The Multi Jet Fusion process is similar to binder jetting technology as it uses a liquid binding agent to create the layers of your object. In addition, a detailing agent is used to obtain fine details and to smooth the surface of the object. Layer by layer, the object is created from the combination of the powder, the liquid agents (fusing and detailing) and the energy (heating process).

The HP process is faster than SLS technology but it still needs to cool. When the parts are 3D printed, the building box is placed into the post-processing station that cools the parts and prepares them for cleaning.

Finishings available HP technology

Here are all options available after the Multijet Fusion 3D printing process:

- Raw: Grey surface with no finish, as it comes straight out of the 3D printer. Ideal for prototyping and mechanical tests. The raw finish provides a surface that is more prone to scratches and impact marks.

- Polished: Grey surface with a smooth finish (tribo -finishing).

- Dyeing with Color Resist finish: A dyeing finish with a matte look that resists friction and allows for more consistent color between different production batches. The available color for this finishing option is black.

- Dyeing with Color Touch finish: With this dyeing finishing your 3D printed part gets a satin look. It withstands daily handling and is the perfect finish for parts that are exposed to external conditions, scratching and rubbing. The available color for this finishing option is black.

| Standard layer thickness | 80µm |

| Accuracy | X/Y: ± 0.3% (minimum of ± 0.3 mm) Z: ± 0.5% (minimum of ± 0.5 mm) |

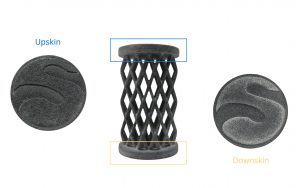

Due to the printing process, your objects will have upskin and downskin. Upskin is a little concave, whereas downskin will show slight convex. Upskin will appear on the top of your object, downskin at the bottom. This is important to consider when you set the orientation of your 3D model. If the upskin and downskin will affect your design, set the orientation beforehand and we will do our best to honor it, otherwise our technicians will choose the best one.

| Maximum size | 370 x 274 x 380 mm |

| Maximum size polished | 300 × 220 × 180 mm |

| Maximum size Color Touch | 274 x 274 x 380 mm |

| Maximum size Color Resist | 274 x 274 x 380 mm |

The maximum size of your models are limited by the physical size of our 3D printers – nothing can be printed larger than the printer bed.

There is no minimum size for polyamide prints, keeping in mind minimum thickness for walls and structural aspects, to ensure the object will not break is 0.6 mm.

| Minimum wall thickness (flexible) | 0.8mm

|

| Minimum wall thickness(rigid) | 2mm

|

| Minimum wall thickness stemmed elements | 0.7mm with support

|

| Minimum wall thickness particular design aspects | 1-2mm |

The walls of your design must adhere to a minimum thickness of 0.8 mm in order to guarantee the structure will not break. If the walls of your model are less than 0.8 mm, you can add a support structure to maintain stability.

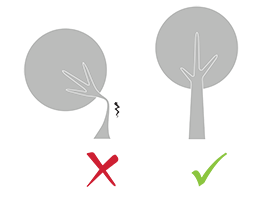

A stemmed element is a design aspect which is at least twice as long as it is thick. For unsupported and stemmed elements or parts of the design with a particular design constraint, it is also important to respect a minimum thickness of 0.9mm in order to guarantee the object will not break.

Add a support structure to maintain stability. For example, if you are modeling a bust of a person, you can attach thin aspects of the design like the ears in more places around the model’s head. Doing that will avoid cantilevered and easily breakable elements in the final print.

With a 0.8 wall thickness, your design will be slightly flexible. To obtain more rigidity, we advise a 2mm wall thickness.

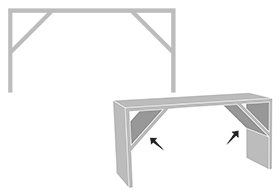

Thin walls supporting large, heavy models can warp under the weight of itself.

Sculpteo offers an online solidity check tool which highlights parts of the print that may be too thin for a print. From there you are able to tweak your design in order to create an object that is an appropriate thickness. To use it, you just need to upload your 3D file, select your material and click on “Verification” tab.

It is also important to keep in mind that the object is to be printed into real life. Thus if a thin aspect is supporting something that is too heavy for it, it may break – even though it is possible within the physics provided by your 3D modeling software. We recommend adding a bit of thickness to the places that will get a lot of handling, or that support the most weight.

Do not forget

Keep in mind that our solidity check tool does not detect physical aberrations such as floating parts, unstable position, parts supporting too much weight relative to their thickness, etc. Particular care must be given to the geometry of your design and the most stressed parts must be thickened.

| Minimum size of details | 0.2 mm |

| Minimum height and width details | Embossed : 0.4 mm

|

| Minimum height and width for a readable text | 0.4mm |

| Enlargement ratio | 1/1

|

A detail’s minimum precision is mainly determined by the resolution of our 3D printers. However, during the cleaning process, a fine layer of detail can also be lost. In order for a detail and text to be visible we recommend following our recommended sizes at the very least.

It’s possible that particularly fine embossings and engravings will not be visible, as the carving could get filled with excess powder that is later unable to be cleaned out. If an embossing or engraving is an essential part of your design we recommend making them as deep as possible. To ensure a better powder removal (thus a better detail visibility), the width of your details must be at least as big as depth.

| Enclosed parts ? | Yes |

| Interlocking parts ? | Yes |

Our Multi Jet Fusion material has the ability to print the most complex designs of our materials thanks to HP technology. An example of a complex design is a volume enclosed within another volume, like a chain or maraca. Our printers have the ability to print a fully interlocked chain, with no support structures to remove.

| Minimum spacing between fixed walls | 0.5 mm |

| Minimum clearance between parts | 0.5 mm |

For a successful 3D print a minimum clearance between objects is required to allow excess material to be sand blown out. If this space is not left within the design, the object will be a solid. This is particularly important for articulated objects – as the space left between the walls will define the object’s ability to move.

Clearance should be at least 0.5 mm, however that is the minumum for small objects. Larger objects require more space between their parts. This is due to the HP printing process. Our printer beds are heated during the process, and larger objects are heated for longer periods. A small space between large objects runs the risk of melting together as it remains under heat for a long period of time. In some other cases, holes should be added to allow us to drain for the excess powder material within the clearance.

| Assembly ? | Yes |

| Minimum space | 0.5 mm |

Objects printed in polyamide can be printed to be assembled. As long as a width of at least 0.5 mm is left between the different parts of the object.

| Hollowing ? | Yes |

Our online hollowing optimization tool has the ability to greatly reduce the price of a print by reducing the amount of material used.

Using the tool requires adding two holes to your model, which will serve as the drain for the excess powder material within the object. The minimum size of these holes is determined by our website. Otherwise it is possible to hollow your object manually in your 3D modeling software.

| Files with Multiple Objects ? | No |

It is not possible to 3D print a 3D file containing several objects with our 3D plastic printers.

They use Multi Jet Fusion PA 12:

From small series to production in a short time

Adaptable headphones to meet customers needs

Related blog posts:

Ready to 3D print with Multi Jet Fusion PA12?

With Sculpteo’s online 3D printing service you’re just a few clicks away from professional Multi Jet Fusion PA12 3D printing. Your 3D model is printed with the highest quality and delivered straight to your door.

Get started now!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook