3D printing materials: The 7 benefits of plastic 3D printing!

Posted By Lucie Gaget on Jun 20, 2018 | 0 comments

“What material should I use for 3D printing?” is certainly the first question that might come to your mind when developing your project. At Sculpteo, we are offering you the possibility to 3D print with a lot of different types of 3D materials. From PEBA plastic to Stainless Steel and polyjet resins, you can choose the material that will perfectly match your expectations. Today, let’s focus on plastic 3D printing and see what are the main advantages of 3D printing with this material. According to our recent study, the State of 3D Printing, plastic materials are still the most used in the 3D printing industry. But why is this material so attractive? How could you make the most of the 3D printing technology using plastic? Discover the advantages of plastic printing right now!

3D printing plastic materials

How does it work

The technology that we use here, at Sculpteo, to 3D print plastic, is called SLS, for Selective Laser Sintering. This is a powder-based technique. This additive manufacturing method creates parts additively by sintering fine polymer powder particles, to fuse them together locally. It will fuse the powder particles together, layer by layer, according to your 3D file.

The HP Multi Jet Fusion technology is also available on our website, offering a great plastic: the Multi Jet Fusion PA12, in its black version or in its non-dyed version. There are different types of plastics that you could use to manufacture plastic projects. Let’s discover their benefits.

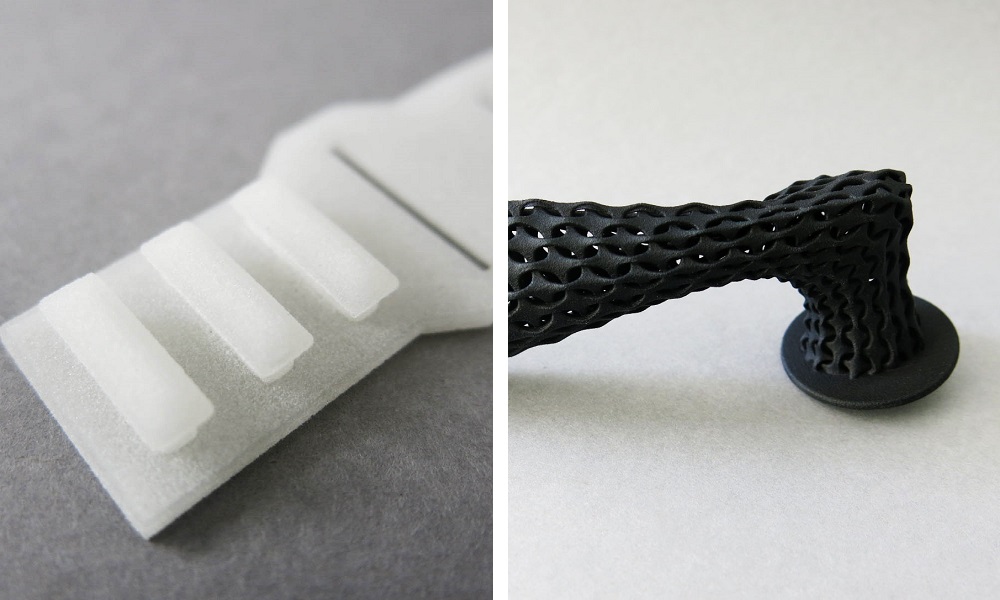

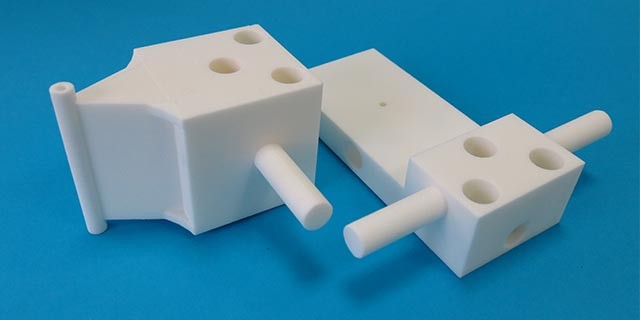

Example of projects made using plastic 3D printing

We saw in our State of 3D printing that plastic was still the most attractive material for 3D printing users. Indeed, 65% of the respondents to our study are using plastic to 3D print their projects. This printing material is followed by metal 3D printing, that is not a real cost-effective manufacturing technique, even if it has numerous benefits. We have made a selection of different 3D printing projects made with plastic. Get inspired by these amazing 3D printing projects.

- 3D printed medical tools

Marc Soubeyrand, one of our customers used the 3D printing technology to create his medical tools. Before that, the surgeon had his tools created by hand. Now that he is printing his custom-made tools using our Nylon PA12 material, and he is saving a lot of time and money.

- Kupol project

Gabriel Boutin developed a 3D printed bike helmet using the HP Multi Jet Fusion technology. 3D printing was the best solution to work on the design of this project, and the PA12 material allowed him to make a light-weight and resistant prototype.

Watch the video for more information about the Kupol Project:

- 3D printed fashion

Flexible plastics such as our PEBA material, or our PA12 and PA11 with a thin thickness, could allow you to work on 3D printed clothes. For instance, Julia Daviy used a vegetable-based plastic to print her collection. Now, plastic can be recycled. Indeed, by recycling plastic you reduce the amount of waste.

credit: https://www.3dprint.com/212640/julia-daviy-3d-printing/

As you can see plastic 3D printing is a great way to give life to many different projects, and there are a lot of different plastic types. But what are concretely the benefits of 3D printing using plastic materials for your 3D printed objects?

What are the benefits of 3D printed plastic parts?

Getting 3D printed plastic parts could be a great advantage for your company. Let’s see 8 reasons why you should use plastic for your 3D printing projects.

You have the choice between different plastics, with different properties

First, when choosing to use plastic to 3D print your project, you will quickly notice that you have the choice among various plastic materials with different properties.

Our PEBA, a flexible plastic, our Nylon PA12, a white plastic, our Nylon 3200 Glass-Filled, our Nylon PA11/12 (Gray), or even the Alumide material: these plastics are available with the Selective Laser Sintering technology. But thanks to Sculpteo, you will also have the possibility to make the most of another efficient technology and print your project with the Multi Jet Fusion PA12.

New kind of plastics such as biodegradable plastics are also developed and could be suitable for your projects in the future.

Benefit #1: 3D printing larger parts

If you need bigger parts for a bigger project, plastic will be the best solution. Indeed, the maximum dimensions that you will find on our 3D printing service are available with the plastic materials, and more precisely with our Nylon PA12. 3D printing bigger projects is now becoming an interesting application for many companies, to get accurate and custom-made parts. However, using additive manufacturing to create big volumes can be quite expensive. As plastic is among our cheapest materials, it will be easier for you to print several parts and then, assemble them.

For the white plastic Nylon PA12 the maximum size that can be produced by our 3D printers is 675 x 366 x 545 mm.

Benefit #2: 3D printing cheaper parts using plastic 3D printing

The price is obviously one of the biggest advantages of 3D printed plastic parts. With the Nylon PA12 material, you can already print affordable parts, but the Multi Jet Fusion PA12 is even cheaper, the HP technology gives you the possibility to print with a low-cost material, very resistant if you pay attention and respect the minimum wall thickness. This kind of material is perfect to prototype in an efficient way, but at a lower cost.

If you are looking for the cheapest option to prototype your project, we launched the perfect option for you! The non-dyed version of our HP Multi Jet Fusion PA12. Check out our full Q&A to get all the details you need about this raw material.

Benefit #3: A more efficient process compared to injection molding

It is not really a coincidence if plastic is the first used material in the 3D printing industry. 3D printing plastic is seen as a cost-efficient alternative to injection molding. Indeed, 3D printing plastic is a way more efficient manufacturing process.

Manufacturing plastic parts using the 3D printing technology has never been so easy, compared to techniques such as plastic injection molding. You don’t need to produce all these molds for your prototyping or production process, you only need a 3D file, that you can upload on a 3D printing service. For each iteration, you just have to work on your 3D model using a 3D software, and then, print it! The process is optimized compared to the process to get plastic molded parts. This method to manufacture plastic improves your product development.

Benefit #4: A useful material, for any sector

We see it every day at Sculpteo, 3D printing is a great asset for various industries. And so is 3D printed plastic! It is used in the medical industry to create tools or 3D models of organs. It can be used in the automotive industry for car parts replacement, to print models for architecture or even for the aerospace industry. Everything is possible, as manufacturing plastic is as simple as child’s play and allows you to reach high levels of details for your 3D printed objects!

Moreover, this material can be useful for every step of your product development process, from proof of concept, prototyping to production! You can print any plastic components, plastic packagings, or plastic products. You will be free to print any kind of complex designs using a plastic.

Benefit #5: Prototyping using plastic materials

Plastic is the perfect solution for your prototyping process! If you are familiar with the additive manufacturing technology, you should know that the 3D printing process is quite advantageous when it comes to prototyping. Indeed, it is the perfect method to do some rapid prototyping as you can make many iterations at a lower price, and very easily, using a 3D modeling software.

Benefit #6: Production using plastic materials

If additive manufacturing is known to be an amazing prototyping method, we also saw in our State of 3D printing 2018 that it was more and more used to produce finished plastic products.

Regarding the quality of the new printing materials, the ability of this technology to produce complex designs and custom-made products, 3D printing is now becoming a great advantage for production. Once again, you can use plastic materials for your finished products. Moreover, the numerous finishing that can be applied on the plastic parts are allowing to create really good looking objects.

Benefit #7: Plastic materials offering a lot of finishes possibilities

While ordering 3D printed plastic parts on our online 3D printing service, you will have a large choice of finishes, which makes this material suitable for many different finished projects. What are the best finishings available at Sculpteo? You will have the Smoothing Beautifier, which will give a glossy and smooth surface to your 3D printed parts. You will be able to manufacture great consumer products thanks to these finishes.

If you are using the Multi Jet Fusion PA12 or the SLS PA12, you will have the Color Touch finish or the Color Resist finish, which has a good resistance to abrasion. These two finishes are a perfect solution if you need to produce resistant parts!

Discover all of our finishes right here!

If you want to go further and find more information about other types of plastics, you can check our glossary. You will find details about PLA and ABS plastic for example. And if you want more information about all the types of the materials, check out our material guide!

As you can see, the benefits of plastic are numerous. All of these types of plastic can help you with any project. Don’t hesitate to check our 3D printing materials page to see in details the properties of our materials and choose what will be perfect for you. When choosing your material for your project, take the time to do a good material comparison to check all the technical specifications of the materials. Do you need a material which is chemically resistant? Heat resistant? Food safe?

Are you ready to use plastic 3D printing? Upload your 3D model right here. Our 3D printing service offers you the best experience thanks to our professional 3D printers.

If you want to know more about the 3D printing industry, subscribe to our weekly newsletter and don’t miss a single post!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook