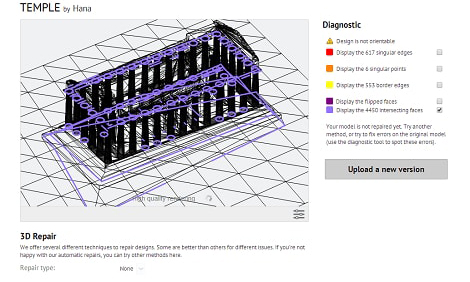

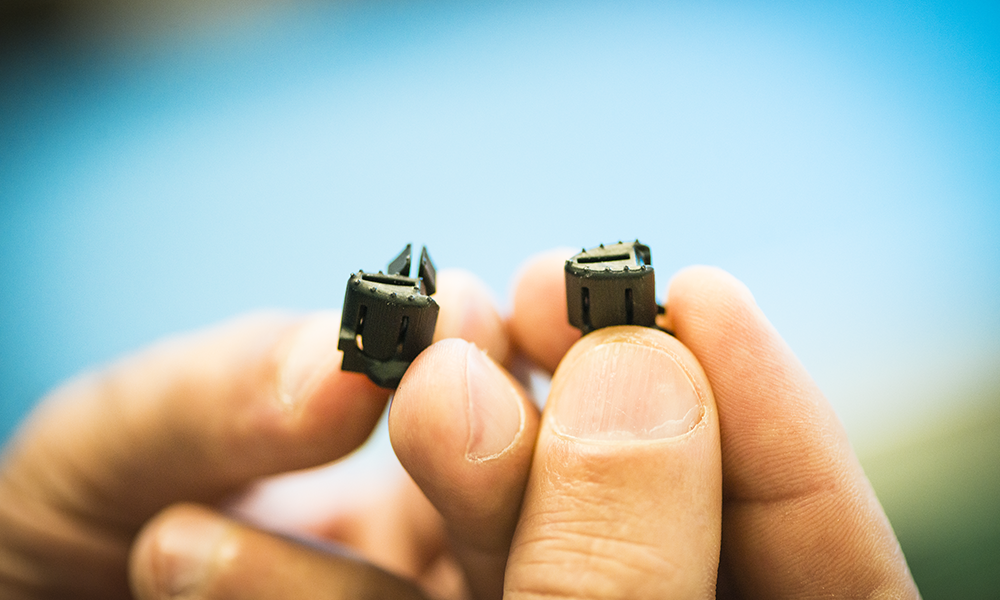

This news was originally published by Carbon. We’re very proud to be part of this project, helping produce board alignment brackets, delivered in days instead of months for other technologies. (Photo credit: Carbon) Additive Manufacturing is no lon...

Read More

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook