Glass printing the next big of 3D Printing trend ? MIT Media Lab & More!

Posted By Amandine Richardot on Apr 26, 2017 | 0 comments

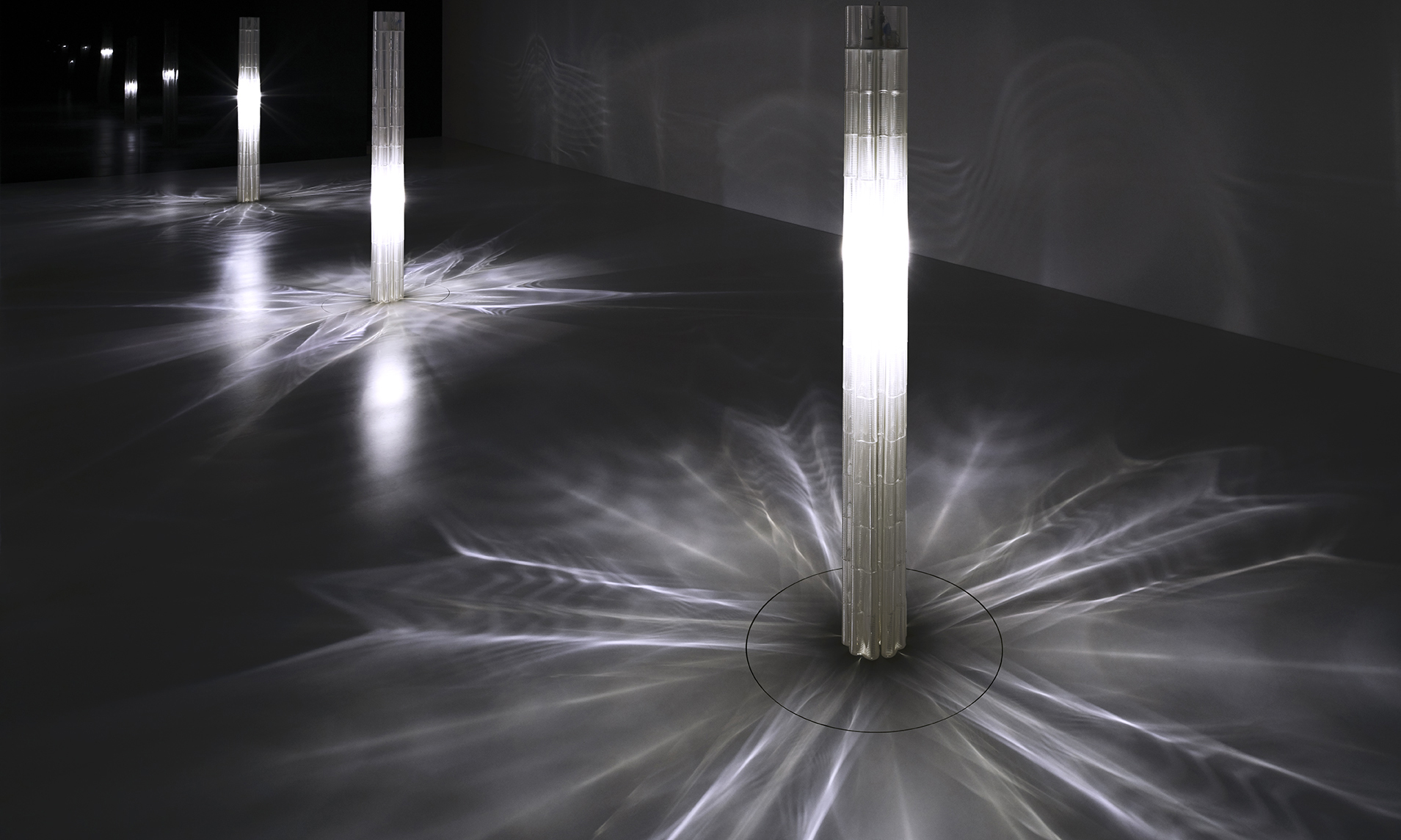

This month, glass 3D printing has been one important trend spotted at the Milan Design Week. Each year, the Lexus Design Award helps young designers turn their concepts into prototypes. For its tenth year of presence at this event, Lexus decided to work with Neri Oxman, architect, designer, and professor of the MIT Media Lab to create an installation for the opening space of the exhibition. Made of 3d printed glass, it opens new possibilities for this technology.

“Ancient Yet Modern”: a revolutionary 3D printed installation

Neri Oxman and her team designed the installation “Ancient Yet Modern”, mixing glass, an “ancient” material, with the “modernity” of glass 3D printing developed by the MIT Media Lab. They created a light-based installation, made of a series of 3-meter high 3D printed glass pillars. There was a traveling light inside of each one, showing the many ways light can refract dynamically.

This is the first time objects are 3D printed in glass at such a large scale. Before, it was only possible to print small objects of maximum 30cm. Thus, it opens new interesting possibilities for glass 3D printing, at a larger scale.

The G3DP2 additive manufacturing technology

Glassmaking is one of the world’s oldest arts. It started to be produced in factories in the middle of the 1900’s, by melting sand, and then by floating sheets of it in vats of molten tin. Researchers are now trying to find new techniques to make glass, and 3D printing is perfect for that since it allows the making of extremely small and complex structures, at lower costs.

To make this possible, the MIT Media Lab developed G3DP2: a large-scale and high-fidelity additive manufacturing technology to 3D print optically transparent glass structures, at architectural dimensions. It includes a digitally integrated thermal control system. It accompanies the various stages of glass forming and is equipped with a first-of-its-kind 4-axis motion control system that allows flow control, spatial accuracy, and precision, as well as faster production with continuous deposition of up to 30kg of molten glass.

This technique involves melting and laying down filaments of material, as you would do with a glue gun. Thus, there is an important technical challenge they did not totally overcome. With this technique, it is quite difficult to create a totally smooth and transparent object, because of the different layers of glass that can be visible. Moreover, it is quite difficult to shape glasses, and especially high-purity glasses such as fused silica glass, since it requires high-temperature melting and casting processes.

Stereolithography is creating new possibilities for Glass 3D printing

Other researchers tried to solve these issues. Last week, a team from Germany presented a new glass making method based on a liquid glass that can be shaped into complex structures with a 3D printer. With this technique, they can create transparent fused silica glass components using stereolithography 3D printers at resolutions of a few tens of micrometers.

How stereolithography for glass 3D Printing works

Stereolithography shapes structures using UV light. The team created a photocurable liquid with a high concentration of glass particles that hardens under this type of light and which can be 3D printed. It is then locally exposed to UV light, according to the 3D file, and creates the object layer by layer. Once 3D printed, the object is heated in a high-temperature furnace, like ceramics kiln, to burn away the leftover liquid and allow full fusion of the glass particles. The material becomes high-quality fused silica glass.

This technique has some important advantages. First of all, it reduces costs and time needed to create detailed or complex glass structures. Another key advantage is that it gives the possibility to easily produce high-quality glass that is smooth enough to make mirrors or lenses said Bastien Rapp, author of the paper and principal investigator at the Karlsruhe Institute of Technology. With this technique, you just have to upload your 3D printing design, and “the software does all the rest” he said.

The potential uses of this technique for Glass 3D Printing

There are many potential applications of Glass 3D Printing. It could be used to create skyscrapers facades in complement to the cement 3D printing techniques that are already used in construction, as well as tiny devices for chemistry and optics research. If the technology improves, it could also potentially be used to make camera lenses or components for light-based computing.

Neri Oxman said the study is “the most detailed demonstration we have seen of the stereolithography technology” with glass. But for now, it is only working at scales of centimeters, while her team is willing to 3D print glass at scales of meters.

These two innovations show that glass 3D printing techniques are evolving quite fast, in promising ways, and could be one of the next big trends and fields of progress in 3D printing.

If you wish to learn more about this topic, you can read our interview of Dr. Brun, instructor of Applied Mathematics at the MIT.

You can also discover our portrait of Neri Oxman, pioneer of 3D Printing.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook