Medical 3D printing: Additive manufacturing for Jaw Reconstruction

Posted By Lucie Gaget on Mar 28, 2018 | 0 comments

We already have already seen in previous blog posts: 3D printing is becoming a great asset for the medical industry. With the evolution of 3D bioprinting, or even dental 3D printing, additive manufacturing has a promising future in the medical field! For example, it is now possible to work on transplants or reconstruction with the use of 3D printing. 3D printing will certainly be even more used in the future as additive manufacturing technology is progressively showing all its capacity, efficiency and accuracy.

In this blogpost, we are going to tell you about 3D printing for corrective jaw surgery! We will see why this 3D printing technology is a major advantage for these kind of reconstructions, and we are going to present you some examples of jaw reconstruction.

3D printing in the medical industry

Mass-customization for the medical field

Additive manufacturing is an advanced technology and is now increasing the possibilities to get on-measure treatments for the patients. 3D printing is offering great solutions to make reconstructions, or to help patients in their daily lives. One the the most important advantages that 3D printing can bring to the medical sector is mass-customization. Indeed, it is a way to get printed parts perfectly adapted to the patient, that will perfectly fit his or her needs and body.

For example, 3D printing is well used to create on measure prosthesis. It is now really common to 3D print prosthesis for arms or legs. Each body and each morphology is different, by using this technology, prosthesis are totally fitting the morphology of the patient and replace correctly his or her missing member. This is why it is now a major benefit, it is enabling more efficient prosthesis, adapted to the mechanical constraints of the body.

Before the printing process, you have to use a 3D modeling software to create your 3D model: thanks to all the software tools, you can easily modify the model and adjust it. Moreover, it is totally possible to add all the features that you need on the part. You just have to 3D model it. If you need help choosing a software, here is our list of the best 3D modeling software for the medical industry.

3D printing allows the development of impressive treatments

Now, you have to realize that additive manufacturing is a great and efficient method to save lives, or help patients to recover. A lot of 3D printing materials and professional 3D printers have been developed in a past few years for medical use, like biomaterials for example.

Additive manufacturing is now allowing the creation of new treatments like bone reconstruction. As we just saw, it is actually one of the first methods to offer the possibility to get devices totally adapted to the patients with good materials and at a lower cost! It is also a way to manufacture the specific tool equipment for a precise surgery. For example, guides for surgical procedures are really expensive: It is much cheaper to 3D print it at a lower price for the same result! With a traditional manufacturing technique, these processes to create tools, prosthesis and body parts would be much more expensive.

Moreover, we can notice that 3D printing technology is an efficient and low cost method to make clinical research, and develop new surgeries, new treatments. Additive manufacturing is often used as an efficient prototyping method, because it allows you to make many iterations at a lower cost and to access a wide range of 3D printing materials.

Reconstruction and real cases of 3D printing for medical applications

3D printing for bone reconstruction?

3D printing bones will be possible in the upcoming years. It will soon be possible to do bone grafts using 3D printing technology. In the future, thanks to the promising evolution of bioprinting, it will certainly be possible to 3D print entire body parts of bones structures, using the patient’s cells.

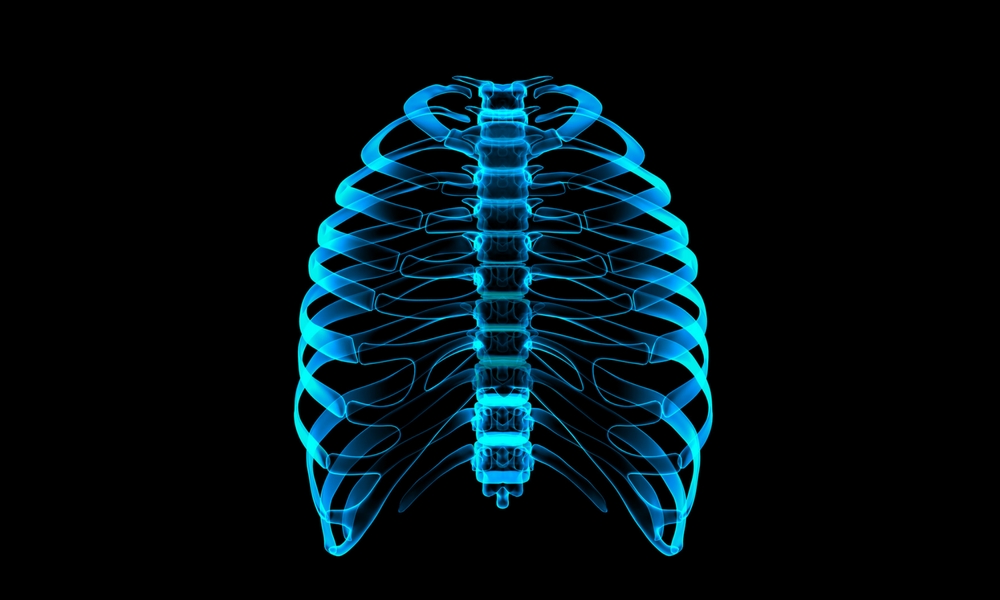

For the moment, this additive technology is used to create reproductions of body parts, using 3D printable biomaterials. If it is possible to make prosthesis for external use, it is also possible to make prosthesis for internal use. Indeed, with the evolution of 3D printers and the creation of new 3D printing biomaterials, new possibilities are offered. We wrote a blog post about a 3D printed rib cage, if you want to know more about this impressive 3D printed prosthesis. Dr. Olivier Pagès explains how it is possible to do bone reconstruction using titanium and additive manufacturing.

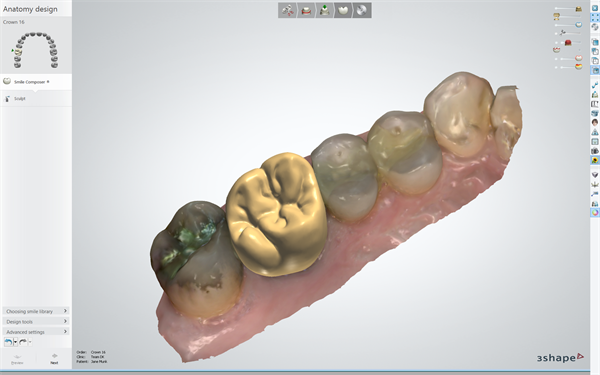

How is 3D printing helping the dental industry?

Dental restoration can be easier using 3D printing. More and more dentists are using a 3D printer in their daily work. They are using desktop 3D printers to create braces, bridges or dental implants for their patients. Why it is such an advantage for them? They can do it by themselves, immediately, and on site, to avoid wasting time and money.

If you are interested by 3D printing in for dental applications, you can read our previous blog post on this subject.

If it is possible to print all of these dental devices and implants, why wouldn’t it be possible to manufacture a whole jaw? Actually, it is possible. Let’s see how!

Orthognathic surgery: 3D printing for jaw reconstruction

Is additive manufacturing a good solution for jaw reconstruction?

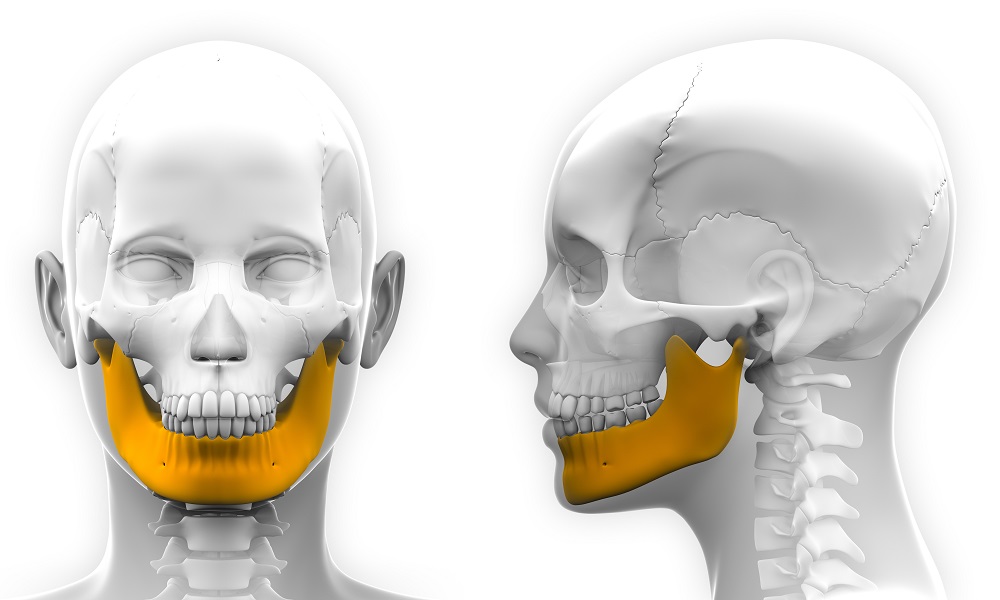

Mandibular reconstruction can happen after an accident, a cancer or a malformation. Additive manufacturing can be really useful for oral and maxillofacial surgeries. Indeed, it is possible to print specific tools or specific equipments in order to perform the jaw reconstruction. But it can also be used to create parts of the new jaw of the patient, adapted to his morphology and to his natural movements.

Moreover, the advanced visualization offered by some 3D modeling software is also an essential asset for the medical industry. It is now possible to get a CT scan and to convert it in the right format in order to get a 3D model that you can manipulate. It allows for the visualization of jaw defects in 3D and creation of simulations to see what it is possible to do.

What has been made regarding jaw reconstruction?

Let’s see how, concretely, some professionals choose to use 3D printing make reconstructive surgery.

3D printer allowing a jaw transplant

In the Netherlands, a 83 years old woman had a jaw reconstruction thanks to 3D printing. She now has a 3D printed jaw with articulated joints! This part has cavities to promote muscle attachment and the growth of new nerves. This 3D printed jawbone has been made with titanium powder and a bioceramic coating. A special dental bridge has been added to the jawbone, in order to implant new teeth to the patient.

Why 3D printing has been used for this surgery? Due to the age of the patient, doctors chose to use this method, saying that it was a little bit less risky than the traditional procedure.

www.bbc.com/news/technology-16907104

The different uses of 3D for surgery

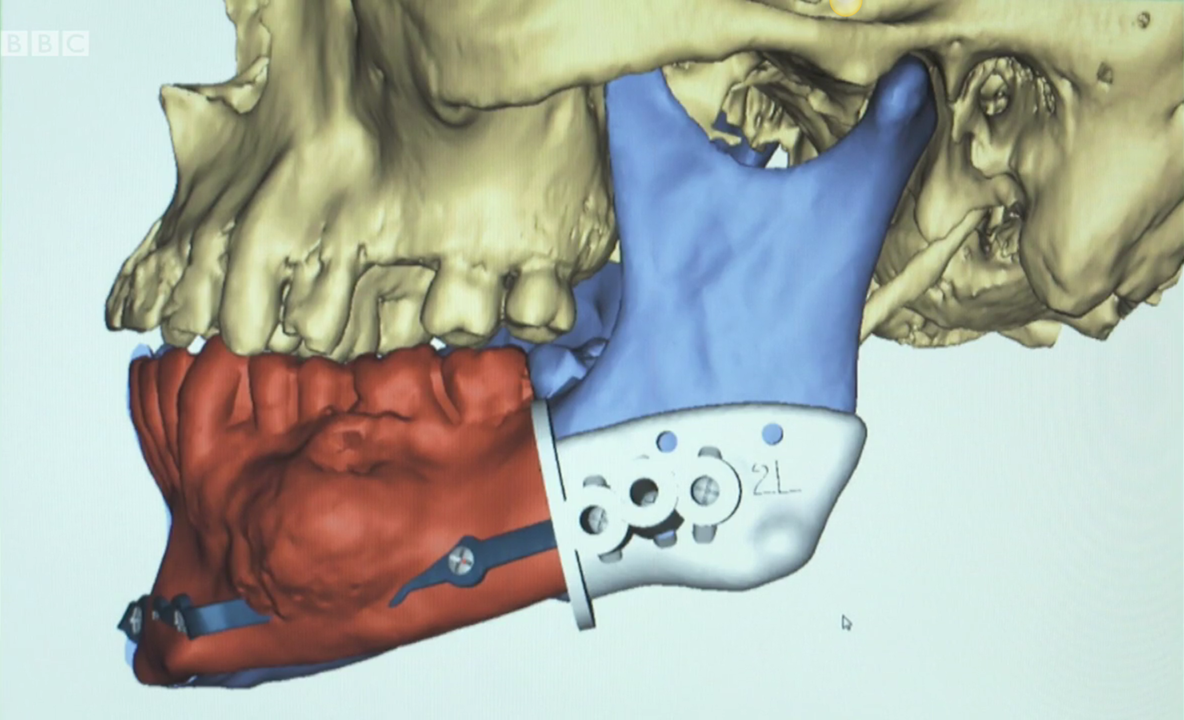

A patient of the Newcastle Royal Victory Infirmary (RVI) had a tumor at his lower jaw so he needed a reconstructive surgery. Doctors had to remove the tumor from his lower jaw, but it wasn’t possible without removing the left side of the jaw. And it also meant removing a lot of teeth.

Doctors used 3D visualization to see clearly the issue and try to solve it. They made 3D printed surgical guides, and titanium plates to perform an impressive jaw reconstruction. The jaw has been reconstructed using a part of the patient’s fibula. The patient needed dental implants, also made using his fibula.

BBC

Usually, when doing jaw reconstruction, different operations are required. Here, all has been 3D printed just one time. The use of 3D visualization has also been quite essential to get a better understanding of the different issues. Now the patient has a perfect and symmetrical result!

The 3D printed mandible

In China, a hospital created a 3D printed mandible for a man that was shot in the face. They actually used 3D printing for two different things: first, they printed a 3D model of the man’s mandible to see exactly where were the jaw defects.

Then, they printed a new one in titanium to implant it, allowing the patient to recover properly. This impressive surgery has been a real success.

It is now possible to 3D print really complex structures with biomaterials that can be used for medical applications, and jaws are one of them. The fact is that titanium is now 3D printable allows the creation of customized parts.

You can now see how 3D printing can be used for reconstruction surgery and more precisely for reconstruction of jaw defects. 3D is helping doctors to get a better visualization of the patient’s issues, to build 3D models, or print 3D implants.

If you are working in the medical industry and want to try 3D printing for prototyping or production, upload your 3D model right now! If you want more news about the applications of additive manufacturing in the medical industry, don’t hesitate to subscribe to our weekly newsletter.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook