Groundbreaking news: 3D printed heart with human tissue

Posted By Kat Plewa on Apr 29, 2019 | 0 comments

The 3D printed silicone heart was already a huge revolution in the medical world, but we just made another step towards the future of manufacturing organs with 3D printing. It might sound a little bizarre, but this development might absolutely change the medical industry. What if we will not have to wait for organ transplants anymore? The perfect matching organ will be 3D printed in the hospital for you in a matter of hours. Let’s find out just how real this vision is.

Why 3D print organs?

What can 3D printing give and how can it improve the medical field? Additive Manufacturing allows for the production of highly customized designs. This aspect of 3D technologies is beneficial for many industries, from automotive to aerospace, and healthcare is no different. There are no two medical cases which are the same, each one requires unique solutions.

Additive Manufacturing enables doctors to design solutions matching exactly their patient’s needs. We already showcased knee replacements, kidneys, and prosthetics, which reached the level of personalization never seen before. 3D printing enables the design of impossible and complex structures like no other technology can.

Another benefit of 3D printing organs is the material they are made of. Thanks to Additive Manufacturing the researchers can use bio-inks and even human tissue! An example of this technology is 3D printed skin, which can be used for treating severe burns. This aspect of 3D printing could potentially eliminate the risk of organ rejection as we would produce the organs with the patient’s own cells.

Lastly, and that goes not only for printing organs, but Additive Manufacturing is also fast. It can produce the design in a matter of hours. In the future, every hospital will have a 3D printer, to which a 3D model can be sent and the organ would be produced for the waiting patients. This could really shorten or even eliminate transplant waiting lists.

The first ever 3D printed heart with human tissue

This revolutionary development came from researchers from Tel Aviv University. This is the first time in history when we were able to use human cells to 3D print a vascularized heart. So far we only were able to produce rather simple tissue samples, but this heart has chambers, cells, and blood vessels. The success of this research proves that we will potentially produce fully functional organs in no time.

Professor Tal Dvir from Tel Aviv University’s School of Molecular Cell Biology and Biotechnology and Sagol center for Regenerative Biotechnology led this amazing research. He points out that “People have managed to 3D-print the structure of a heart in the past, but not with cells or with blood vessels. Our results demonstrate the potential of our approach for engineering personalized tissue and organ replacement in the future.”

How does it work?

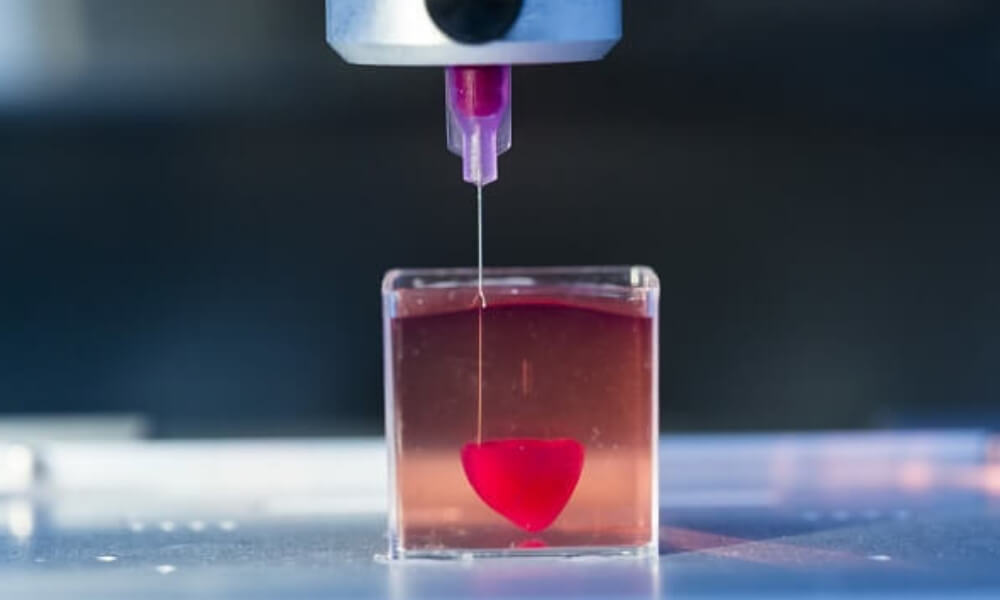

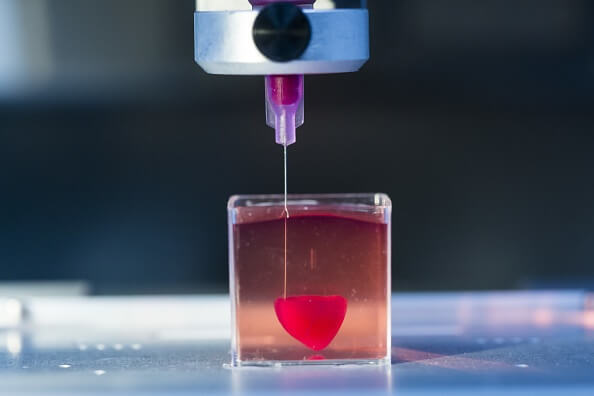

Firstly a biopsy on the patient’s fatty tissue has to be completed. The sample was then separated into cellular and acellular. Next, the cells were reprogrammed to perform as pluripotent stem cells. Those cells were mixed with other biomaterials such as collagen to produce bio-ink. It’s important to mention that the bio-ink itself is outstanding as it eliminates the risk of organ rejection. The heart was then 3D printed it a support bath.

Professor Tal Dvir explains: “This heart is made from human cells and patient-specific biological materials. In our process, these materials serve as the bio-inks, substances made of sugars and proteins that can be used for 3D printing of complex tissue models. Ideally, the biomaterial should possess the same biochemical, mechanical and topographical properties of the patient’s own tissues.”

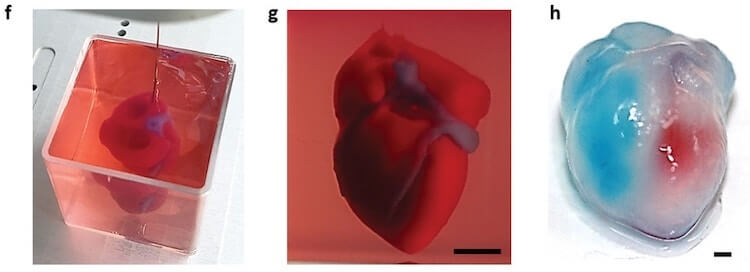

On the picture below we can observe the 3D printed heart in support gel. After it was taken out of the bath, blue and red ink was injected to demonstrate septum and hollow chambers.

What is next for the 3D printed heart?

Right now the heart is small, the size of rabbits heart; the next step is to scale it up and teach it how to behave as a normal organ. When the 3D printed heart is ready, it could be tested on animal models. Professor Dvir reports that the cells of the 3D printed heart can contract, but they need to learn how to pump blood. The future of 3D printing organs is definitely bright.

As you can see, there are plenty of benefits of Additive Manufacturing, and they don’t apply just to medical 3D printing. Indeed, 3D technologies are fast, give you a wide choice of materials and can produce complex and personalized designs. So don’t wait any longer and upload your 3D files right now. If you’re unsure about technology or material you should use, contact us and our 3D printing experts will guide you.

Sign up to our Newsletter and follow us on Facebook to stay up to date with the latest 3D printing news!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook