Sculpteo Success Story: 3D printed medical tools for surgery

Posted By Arthur Cassaignau on Oct 28, 2015 | 0 comments

Last week, we dedicated a blog post to the latest changes that took place in the medical industry thanks to 3D printing. Not much changed since a week, however we got to talk in detail with Dr Marc Soubeyrand who explained why 3D printing was a major advantage for him and how being able to create customized product on demand changed the way he practiced surgeries. Above all, Dr Marc Soubeyrand found 3D printing useful in every aspect of his professional life, both as an orthopedic surgeon at the CHU Bicêtre hospital and as a researcher. Let’s discover more about 3D printed medical tools.

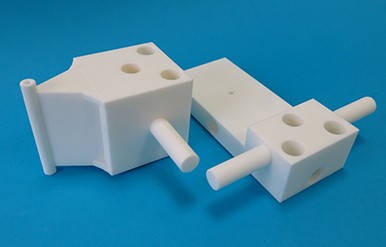

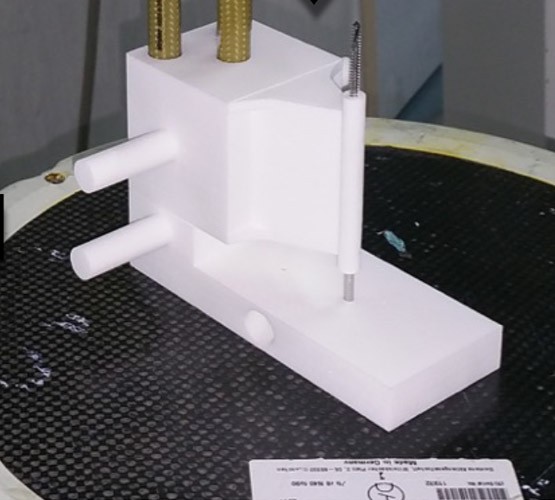

Dr Marc Soubeyrand has been using 3D printing for a couple of years now. Mainly to help him with two different aspects of his professional life. First as an surgeon. One of the main challenges for an orthopedic surgeon is to be able to position prosthesis and implants with the utmost precision. To help them in this matter, they use what is called an ancillary tool. The basic function of an ancillary tool is to guide the surgeon when positioning a prosthesis. Of course, the right position is a relative matter since every individual has his own physical characteristics. Therefore when being given the choice between a tool that is only defined by a range of different sizes and a fully customized one with the patient’s data, the choice is pretty obvious.

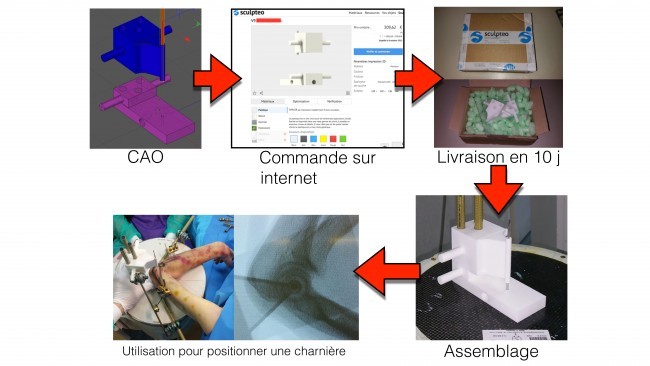

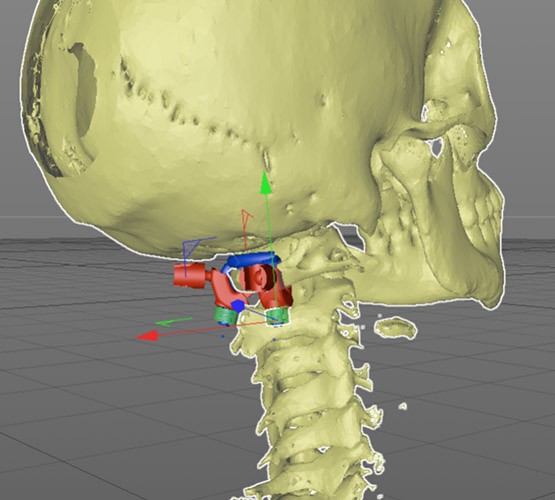

In the process of preparing for a surgery, Dr Marc Soubeyrand is first compiling the patient medical imaging (in this case from CT scans) to turn them into a proper 3D file. To do so, he’s using a software called Osirix (by the way, there is more to read about this topic on Instructables). Importing the result into Cinema 4D allows him to create the 3D printed medical tools he needs for the surgery.

The 3D prints are then used to guide the surgeon during the surgery and make sure the implants are positioned perfectly.

“Before turning to 3D printing, all the tools I used had to be manufactured by hand. It became clear very quickly that 3D printing would help me to save time and money, making this kind of use within reach of most healthcare professional” – Dr Marc Soubeyrand, Surgeon at CHU Bicêtre

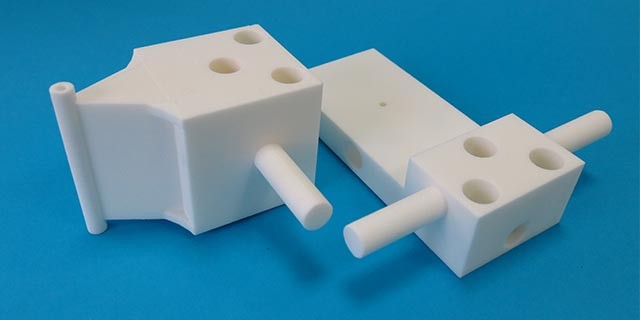

To create those 3D printed medical tools, the surgeon has been using a plastic material, very common in SLS 3D printing. This 3D printing technology allows for the production of very accurate parts made out of a nylon (PA 12). The main upside of this material is that it’s bio-compatible and that it can also be sterilized if needed. At the same time, it’s strong enough to resist a large range of possible uses while remaining flexible on thin sections of a design. If you’re curious about this plastic material, there is plenty of information in our resources center.

For Dr Marc Soubeyrand, this way of using actual 2D imaging from patient and turning it to a whole new level of use is part of the future of the healthcare industry. As for many other industries, there is already plenty of data available but often we are not harnessing it efficiently or even not harnessing it at all. Instead of just looking at the medical imaging, it can be used to make tools that are made-to-measure for each patient. Dr Marc Soubeyrand told us that he took the initiative on his own, but he’s seeing more and more doctors eager to fully embrace those technologies. The result is simply to give the patient the best possible treatment and confort.

The next natural step in this direction is not only to produce tools and parts that helps the surgeon position implants and prosthesis, but also to directly manufacture those on the same basis as the ancillary tools. Following his first experiment a few years ago, Dr Marc Soubeyrand has been prototyping various implants using the same process. To this point, they remain at the prototyping phase as integrating them in a human body would mean to print material that won’t be rejected be the human body. For surgeons as Dr Soubeyrand, this is the next barrier: being able to easily design and manufacture made-to-measure implants that can be added during a surgery. In this race, Dr Marc Soubeyrand has made lots of theoretical experiments.

As Dr Marc Soubeyrand, if you want to discover how we can help you to develop your medical devices with 3D printing, you can visit our Healthcare & 3D printing dedicated page.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook