Can Additive Manufacturing heal bones with a 3D printed cast?

Posted By Kat Plewa on Apr 29, 2019 | 0 comments

Have you or one of your friends ever broke a bone? Probably yes. Maybe you even had your cast signed by all your friends. This is probably the only fun part of wearing a cast. Otherwise, it’s uncomfortable, heavy and not very hygienic. But this can change thanks to Additive Manufacturing! There are already companies out there producing 3D printed casts. Let’s have a look at the best projects.

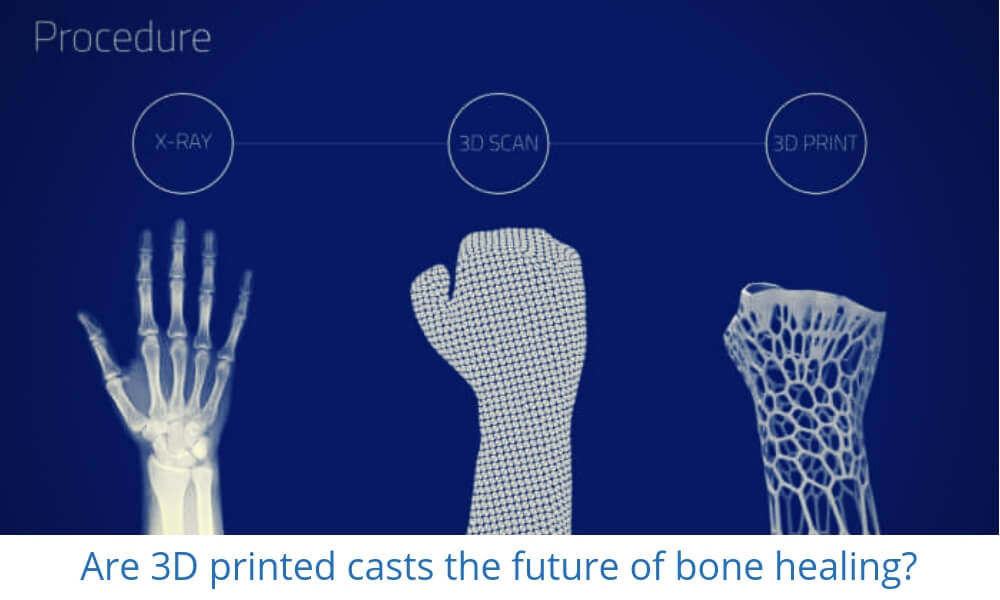

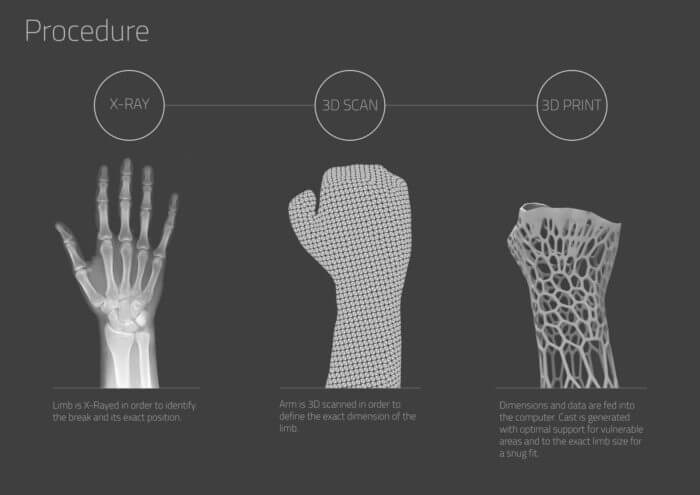

How are 3D printed casts made?

The procedure of producing a cast with Additive Manufacturing is pretty simple and painless.

All you need is a 3D scan, which nowadays, is very easy to do. You can find out how 3D scanning works here. There is plenty of automated software which will create the cast in just a few clicks perfectly fitting the 3D scan of a limb.

3D software also allows to personalize the designs and optimize them. Thanks to that, the cast is lightweight. Different companies also add clipping systems for the cast to be easily removable. On top of all of that, Additive Manufacturing allows creating stylish looking casts which are both functional and fun.

The benefits of using a 3D printed cast

Why would anyone 3D print a cast? First of all, Additive Manufacturing allows for the ultimate personalization. It can produce parts matching exactly the other object, hands, hips or legs. The comfort of wearing a 3D printed cast and a traditionally manufactured one is not even comparable. 3D printing gives the ultimate comfort while the healing process of broken bones is completed.

3D printed casts are also filled with lattices. Lattices are structures which aim is to optimize the design to support the most vulnerable areas. They also make the object lightweight. When it comes to casts, it is a very important topic. Traditional plaster casts are heavy and usually have to be used for weeks. They also don’t let any air through and make it hard to shower. Additive Manufacturing eliminates all of that with the solution of creating beautiful, but most of all, functional lattice structures.

Thanks to 3D printed casts the user can easily shower or wash their hands as the cast is waterproof. Lattices mentioned above allow the air to flow freely making the cast much more comfortable to use. Those aspects also make 3D printed casts quite weather resistant. In summer, they won’t make the limb sweat as plaster casts do and in rainy or snowy seasons, the cast is safe as it’s waterproof and easier to cover.

https://www.treehugger.com/sustainable-product-design/3d-printed-casts-broken-arms-bespoke-3d-systems.html

Another aspect of traditional casts which is troublesome is taking it off. It has to be removed with scissors by a doctor and the procedure can be awkward and painful. Additive Manufacturing solves that with clips. Thanks to the high level of customization, a system to open and close the cast can be designed to make it the process of removing the 3D printed cast efficient and smooth.

Lastly, plaster casts are not that pretty. Additive Manufacturing can improve even that as you could 3D print any design you can imagine in many colors. This makes 3D printed casts fully functional, allowing the bones to heal in a fashionable style. We will introduce to you a great example of this aspect in the next part of the blog post!

Top 4 3D printed cast projects

There are quite a few options already on the market when it comes to 3D printed casts. Would you like your best friends’ message on your cast? Or maybe you would like your cast to express your personality with a strong color? Let’s have a look what’s in store for you!

Cortex Cast

This company is one of the pioneers in 3D printing casts. Ollie and Jake Evill designed their first 3D printed cast in 2013. Since then they developed a localized support system filled with lattice structures. The cast is shower friendly, lightweight and ventilated.

It is designed with x-rays and 3D scans of the patient’s limb to fit the user most comfortably. It also provides the best security for the bone fractures to heal properly thanks to the support system. Cortex Cast has snap fits as a solution to easy assembly.

NovaCast

Developed by a Mexican startup, Medi Print in 2016; NovaCast provides the user with a water-resistant, easy to use, and comfortable cast. What makes it stand out? The automatized first stage of design: the 3D model.

As we already mentioned, most 3D printed casts require 3D scans to be made first. NovaCast, however, decided to change that system. The researchers came up with an algorithm which calculates the design of the cast based on data provided by doctors. This solution can speed up the manufacturing process even more and the patient can receive customized 3D printed cast in as little as three and a half hours.

ActivArmor

As the name suggests, those 3D printed casts are strong and durable. Made out of a high-temperature thermoplastic they are also water safe and personalized just for the patients needs thanks to 3D mapping. They come in different colors and also allow the patient to stay active without making the injury worse.

Fathom

Yet another approach to a 3D printed cast is adding to it an even more modern twist: social media. How? Their #CAST (pronounced hash cast) is definitely unique and uses your social media to create the design of the cast.

As with most of the 3D printed casts, a 3D scan is needed. Then Fathom’s mobile app scans your social media and gathers a word cloud with the most popular words. Then it generates a design for the 3D printed cast. Sounds pretty cool, doesn’t it?

Ava DeCapri, industrial design at Fathom explains: “While discussing the amazing benefits of the various 3D printed cast designs, we became very focused on the users experience from an interactive standpoint. It’s classic to see personalized notes written in marker on a traditional cast. That’s when we realized a big part of the user experience was missing. We asked ourselves, how else could 3D printing uniquely aid in elevating a user’s experience? Our goal was to create a cast concept that was familiar, yet exciting and innovative.”

On the tech side, the cast is designed with Rhino 3D modeling software and produced with Selective Laser Sintering technology and Nylon material. It is breathable, the letters make a lattice structure providing a lot of comfort and good grip for the bones to heal correctly.

Would you wear a 3D printed cast?

Hopefully, you won’t break any bones anytime soon, but the idea of a quickly produced, customized, comfortable and waterproof cast is still quite impressive. Additive Manufacturing is truly changing the face of medicine. From 3D printed skin, knee replacements, prosthetics to organs, 3D printing is bringing a new revolution to improve and even save our lives.

We just talked about SLS technology and Nylon, did you know that you can use it for your production without leaving your house? Online 3D printing services, like Sculpteo, make it possible and bring the latest innovations to your doorstep. It’s as easy as uploading your 3D file or contacting our 3D printing experts for any advice you need.

Make sure you don’t miss out on the next dose of fascinating 3D printing news with our Newsletter and Facebook!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook