Home » Los Materiales de Impresión 3D » Tecnología Jet Fusion para impresión 3D » Ultrasint® TPU01

Ultrasint TPU01®

Colores

Acabados

Caracteristicas

Guía de material Ultrasint® TPU01

¿Qué es MultiJet Fusion TPU?

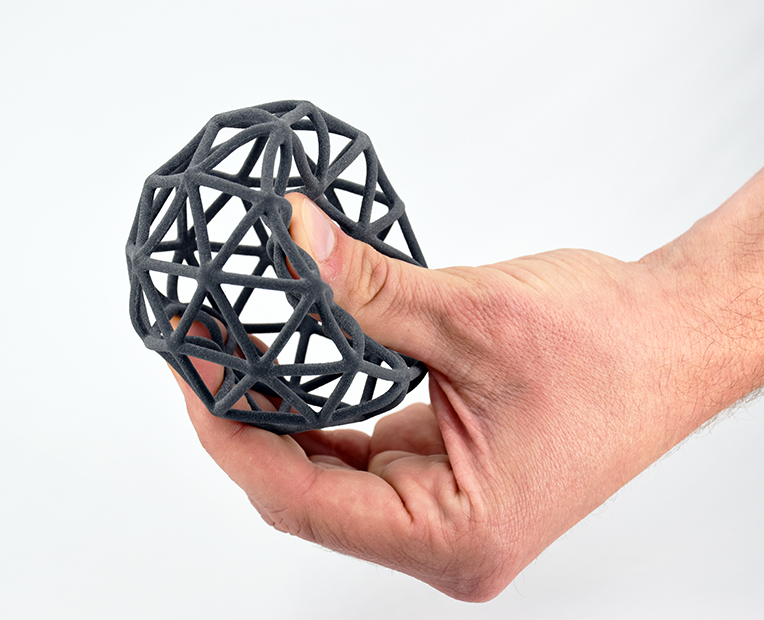

Los objetos Multijet Fusion TPU (o MJF TPU) impresos a través de Sculpteo se crean a partir de un fino polvo de poliuretano termoplástico. Este material ofrece piezas duraderas, fuertes y flexibles. MultiJet Fusion TPU es una elección perfecta de material de impresión 3D si necesita producir piezas que requieran absorción de impactos, alta elasticidad y retorno de energía. Para celosías flexibles y piezas complejas, este material es ideal.

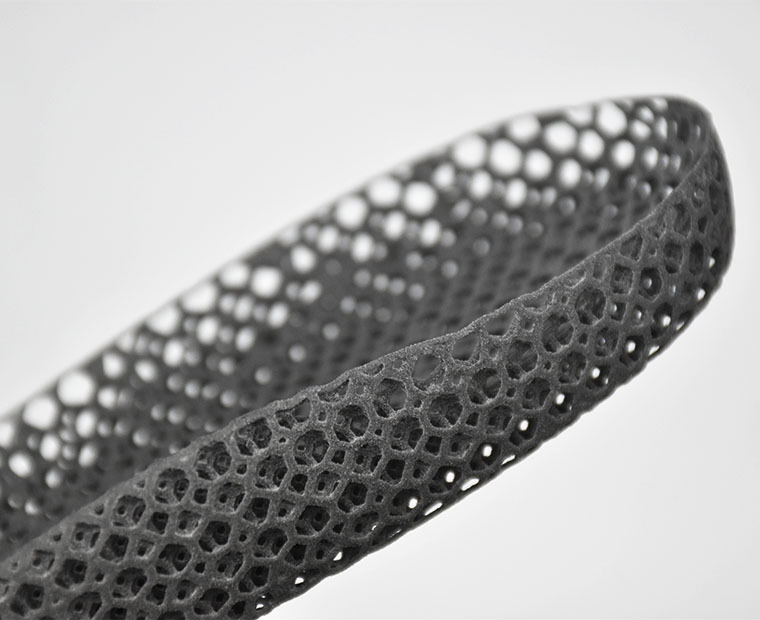

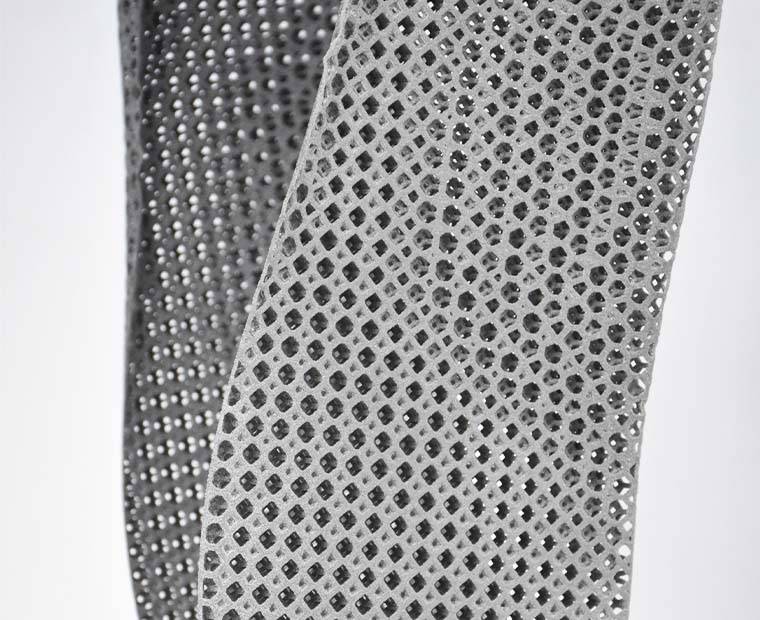

Al salir de la impresora 3D, las piezas de TPU son grises. TPU también ofrece una buena calidad de superficie y un gran nivel de detalle. Este TPU desarrollado por HP ofrece un conjunto de alto rebote, baja compresión, buen comportamiento a la fatiga y se adapta perfectamente a la producción en serie.

Para aprovechar al máximo los beneficios de este material de TPU, tenga en cuenta que deberá respetar el grosor mínimo de la pared del material para evitar cualquier problema durante el proceso de fabricación aditiva. Asegúrese de consultar las pautas de diseño del material al crear su archivo 3D. Además, la información relacionada con el módulo de tracción, la resistencia química o la temperatura de deflexión térmica para este material HP está disponible en la sección técnica de esta página de material.

¿Cuáles son las posibles aplicaciones para este material?

Nuestro flexible TPU Multijet Fusion tiene excelentes propiedades mecánicas. De hecho, este material ofrece versatilidad y puede usarse para muchas aplicaciones diferentes.

- Flexibilidad

Con su flexibilidad, Multijet Fusion TPU también se puede utilizar en la industria automotriz, por ejemplo, para crear componentes interiores de automóviles. Las cubiertas del filtro de aire, el cardán de fuelle, cualquier pieza flexible y resistente necesaria en la industria automotriz pueden imprimirse en 3D con TPU.

- Similar a la goma

Las piezas que requieren el uso de una elasticidad similar a la goma o celosías flexibles se pueden imprimir fácilmente en 3D con este material. Desde la creación de prototipos funcionales hasta la producción, estas propiedades de los materiales ofrecen muchas oportunidades.

- Absorción de impactos

Gracias a su calidad, alta flexibilidad, absorción de impactos y rebote, nuestro TPU Multi Jet Fusion se puede utilizar para fabricar calzado, modelos ortopédicos y equipos de protección deportiva.

Tiempo de proceso y precio

El precio de impresión de su diseño se calcula automáticamente en el momento en que se carga. A medida que modifica su objeto (cambio de material, acabado, tamaño, uso de control de lotes o función de vaciado, etc.) notará que el precio cambia automáticamente. El precio se basa en una serie de factores, incluido el volumen total, el tamaño del objeto y el cuadro delimitador, por nombrar algunos.

El tiempo estimado de envío también se calcula automáticamente a medida que se carga el objeto y cada vez que realiza una modificación en él. El tiempo de entrega debe agregarse al tiempo de procesamiento.

Para obtener más información, consulte nuestra página de precios.

¿Cómo funciona la tecnología de impresión 3D HP?

El proceso de la tecnología Multi Jet Fusion es similar a la tecnología de inyección de aglutinante, ya que utiliza un agente aglutinante líquido para crear las capas de su objeto. Además, se utiliza un agente de detalle para obtener detalles finos y para suavizar la superficie del objeto. Capa por capa, el objeto se crea a partir de la combinación del polvo, los agentes líquidos (agentes de fusión y detallado) y la energía (proceso de calentamiento).

El proceso HP Multi Jet Fusion es una tecnología de lecho de polvo que es más rápido que la sinterización selectiva por láser. Después de que las piezas se imprimen en 3D, la plataforma de construcción se coloca en la estación de procesamiento posterior que enfría las piezas y las prepara para su limpieza.

Tamaño máximo | Crudo : 274 × 370 × 380 mm |

El tamaño máximo de sus modelos está limitado por el tamaño físico de nuestras impresoras 3D: no se puede imprimir nada más grande que la cama de la impresora. |

| Espesor de capa | 100µm |

Tolerancias dimensionales obtenidas durante la caracterización para una capacidad de proceso objetivo de Cpk = 1.33 (4 sigma).

| Dimensión nominal | |||||

|---|---|---|---|---|---|

| 0 – 30 mm | 30 – 50 mm | 50 – 80 mm | |||

| YX | Z | XY | Z | XY | Z |

| ± 0.44 | ± 1.05 | ± 0.52 | ± 1.35 | ± 0.66 | ± 1.80 |

| Espesor mínimo de pared (flexible) | 0.8mm |

| Espesor mínimo de pared con soporte | 1mm |

| Espesor mínimo de pared sin soporte | 1.2mm |

Detalles mínimos de altura y anchura | Grabado en relieve: 0.7 mm

|

| Relación Profundidad / ancho | 1/1

|

La precisión mínima de un detalle está determinada principalmente por la resolución de nuestras impresoras 3D. Sin embargo, durante el proceso de limpieza, también se puede perder una fina capa de detalles. Para que un detalle y un texto sean visibles, recomendamos seguir al menos nuestros tamaños recomendados.

Es posible que no se vean grabados y estampados particularmente finos, ya que la talla podría llenarse con un exceso de polvo que luego no se puede limpiar. Si un grabado en relieve o grabado es una parte esencial de su diseño, recomendamos hacerlo lo más profundo posible. Para garantizar una mejor eliminación del polvo (por lo tanto, una mejor visibilidad de los detalles), el ancho de sus detalles debe ser al menos tan grande como la profundidad.

| ¿Partes cerradas? | Si |

| ¿Partes entrelazadas? | Si |

Nuestro material tiene la capacidad de imprimir los diseños más complejos de nuestros materiales. Un ejemplo de diseño complejo es un volumen encerrado dentro de otro volumen, como una cadena o una conexión de rótula. Nuestras impresoras tienen la capacidad de imprimir una cadena completamente entrelazada, sin estructuras de soporte para eliminar.

| Distancia mínima entre paredes fijas | 0.5 mm |

| Separación mínima entre partes | 0.5 mm |

Para una impresión 3D exitosa se requiere un espacio libre mínimo entre los objetos para permitir que el material sobrante se expulse con arena. Si este espacio no se deja dentro del diseño, el objeto será sólido. Esto es particularmente importante para los objetos articulados, ya que el espacio que queda entre las paredes definirá la capacidad del objeto para moverse.

No se olvide

El espacio libre debe ser de al menos 0,5 mm, sin embargo, ese es el mínimo para objetos pequeños. Los objetos más grandes requieren más espacio entre sus partes. Nuestras camas de impresora se calientan durante el proceso, y los objetos más grandes se calientan por períodos más largos. Un espacio pequeño entre objetos grandes corre el riesgo de derretirse, ya que permanece bajo calor durante un largo período de tiempo. En algunos otros casos, se deben agregar agujeros para permitirnos drenar el exceso de material en polvo dentro del espacio libre.

| Hollowing ? | Yes: 5mm |

Nuestra herramienta de optimización de huecos en línea tiene la capacidad de reducir considerablemente el precio y el peso de una impresión al reducir la cantidad de material utilizado.

El uso de la herramienta requiere agregar dos agujeros a su modelo, lo que servirá como drenaje para el exceso de material en polvo dentro del objeto. El tamaño mínimo de estos agujeros está determinado por nuestro sitio web. De lo contrario, es posible vaciar su objeto manualmente en su software de modelado 3D.

¿Listo para imprimir en 3D con Ultrasint® TPU01?

Con el servicio de impresión 3D en línea de Sculpteo, está a solo unos clics de la impresión 3D profesional de Multi Jet Fusion TPU. Su modelo 3D se imprime con la maxima calidad y se entrega directamente a su puerta.

Conéctate con Google

Conéctate con Google Conéctate con Facebook

Conéctate con Facebook