Is 3D Printing a Threat to the Workforce? 6 Questions & Answers

Posted By Hannah Bensoussan on Nov 9, 2016 | 0 comments

Automation, AI, collaborative platforms, freelance work, uberization, on-demand consumption, outsourcing, globalization… As we are bathing in what is often called Industry 4.0 or The Fourth Industrial Revolution, many factors seem to be on their way to making work as we know it obsolete. Many fear that their jobs will be replaced by robots in the next few years, and that the only way to keep the population from suffering from the upcoming increase of unemployment is to adapt to a jobless (or job-scarce) economy, thanks to, for example a universal basic income system. Our question today is: is 3D printing one of those “threats to the workforce”? Are 3D printers coming for our jobs? 6 questions and answers to try and make it all clearer.

The World Economic Forum’s Report on The Future of Jobs

The present article is in part based on the World Economic Forum’s Report on The Future of Jobs. This report was conceived thanks to the answers of HR managers, CEOs and CHROs of 371 companies from every continent, representing more than 13 million employees in 9 key industries (infrastructure, consumer, energy, financial services & investors, healthcare, ICT, media, mobility and services). It’s interesting to keep in mind, first of all because I invite you to check it out (it is a great read and goes beyond our argument of today, including a part about the Industry Gender Gap), and second of all so that you can put our information in context – even if it comes from a large pool of influential respondents, it stems from opinions rather than studies and fact checking.

1) For quick context about changes in consumption patterns: What is the Fourth Industrial Revolution?

It’s been explained times and again, and is not exactly the subject of this article, so I’ll be quick: 3D printing as a change or a threat for the workforce needs to be taken in context. Consumption and production are changing drastically, both in how we consume and produce and in what we consume and produce.

- Information is omnipresent, through mobile internet and cloud technology

- Everything is connected and tracked through the internet of things and big data

- Relationships become more and more horizontal with the rise of crowdsourcing and peer-to-peer platforms

- Consumers are getting used to on-demand consumption and mass customization

- Ethical concerns about consumption and production are more and more present, which means favoring environment-friendly materials and processes and local production will be more and more important

- New technologies need to be integrated and understood in production processes (digital manufacturing – including 3D printing -, AI, advanced materials, biotechnology, IoT…)

To all of this are added socio-economic, geographic and political changes and instabilities. This is just a broad panorama of the many changes that manufacturers, commercials, producers, employers, educators,… etc need to adapt to, today.

To quote the WEF report:

“While these impending changes hold great promise for future prosperity and job creation, many of them also pose major challenges requiring proactive adaptation by corporations, governments, societies and individuals. As whole industries adjust and new ones are born, many occupations will undergo a fundamental transformation. Together, technological, socio-economic, geopolitical and demographic developments and the interactions between them will generate new categories of jobs and occupations while partly or wholly displacing others. They will change the skill sets required in both old and new occupations in most industries and transform how and where people work, leading to new management and regulatory challenges.”

2) Will 3D printing replace traditional manufacturing?

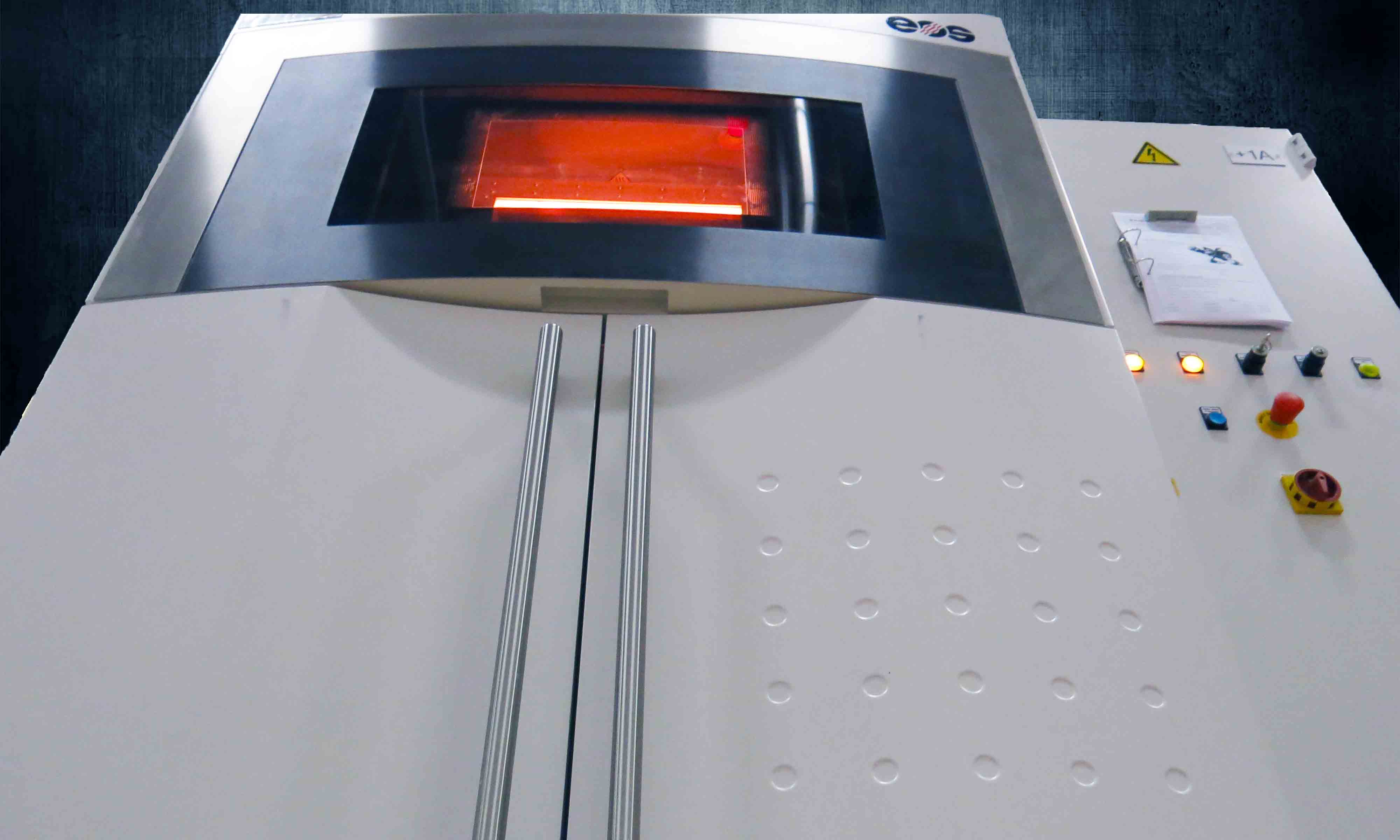

It’s important to address a common myth about 3D printing: as far as we know, 3D printing will not replace traditional manufacturing in the foreseeable future. It’s easy, when you’re an outsider to the field, to imagine 3D printing magically creating every object we need on the click of a button, and make obsolete injection modeling and traditional assembly lines, thus destroying a wide range of factory jobs.

It’s true that 3D printing will be more and more present in factories – see our CEO’s article about the factory of the future in Fabbaloo -, and the range of materials and shapes it will be able to use is growing – see for example the visionary research by Neri Oxman. But the technology is far from being able to print every object, and doesn’t have a vocation to replace traditional manufacturing: we wrote many articles on the subject, that you can read here, here and here. 3D printing, and other digital manufacturing techniques are a great complement to traditional manufacturing techniques, not a replacement.

3) Will 3D printing services and on-demand consumption replace “normal” consumption?

Another myth is that thanks to online 3D printing services and desktop 3D printing, there will be no more need to buy objects as we have so far: from a distributor who sells mass produced identical goods, whether in a shop or online. The idea is that everybody will have access to a 3D printer, whether an SLS or SLA one (through an online 3D printing service) or an FDM one (in a fablab or at home), and will design objects depending on their need, and 3D print them. This would mean a great decrease in transportation costs and wastes, since production would only answer to a need. It becomes a true ecologic dream when you imagine the fantastic sustainable materials that will have been developed by then. It also becomes an employment nightmare, when you think of all the jobs in distribution that would become extinct.

Though it is true that 3D printing has the potential to increase customization of goods, we are a long way away, for one major reason: 3D printing requires a high level of technical knowledge, whether it is in terms of CAD design, mechanical properties of the materials, or functioning of the machines. Thankfully, education in the matter of 3D printing is growing (see our Graduate in 3D printing series), but it is not the huge immediate threat to the current order that one could imagine.

We can hope, however, that since the consumption options are multiplying, through 3D printing, but not only (also through the collaborative platforms, etc), this will push more and more manufacturers to rationalize their offer: reduce waste, increase sustainability…, to make their offer worthwhile.

A good parallel to make is that of the cinema industry: the disruption observed was online practices and the rise of piracy, the consumer getting used to on-demand consumption of video media. An answer to this was platforms like Netflix, offering unlimited content for a fixed monthly fee, and a constant effort to make the offer as good as possible. What will the answer of the industry be to the growing habit of on-demand production? An interesting example, observable already, is Local Motors, which builds personalized, 3D printed cars, in local micro-factories.

4) Will 3D printing replace handicraft? Confusing Mass-Produced and Machine-Made

3D printing is sometimes difficult to grasp, because a 3D printed object is both custom-made and machine made. Many people confuse mass-produced and machine-made, and assume that a machine basically operates on its own. Far from replacing handicraft, 3D printing allows, a sort of “handicraft 2.0”: designers and artists can design very specific objects with their own sensibilities, and sculpt them with a 3D printer rather than in clay, and use the technology to complement the existing creation techniques. It’s important to remember there is craft in using such a machine, both when it comes to design and to operation.

A good example is the Virus Collection, created by the fashion designer Anastasia Ruiz, using our 3D printing services.

5) Will 3D printing make construction workers redundant?

As we read more and more about the construction sector being revolutionized by 3D printing, 3D printed homes, cement 3D printers, and (to go back to Neri Oxman) wide-range 3D printing construction platforms, one can wonder where will the construction jobs go in the next few years. Of course I don’t have an answer to this, but it takes me to my next point.

This picture shows the range of the digital construction platform

6) Creative destruction: Is 3D printing is a disruption rather than a threat?

3D printing, as you’ve probably understood by now, is a disruption more than a threat. Of course, when combined with a whole lot of other disruptions, in a context of rapid and drastic change, it gets scary and confusing.

But, like any innovation, it is part of a creative destruction process: innovation means some old jobs become obsolete when new ones are created. Perhaps the robot revolution that will take away all jobs is coming, but 3D printing won’t be its leader: 3D printing requires specific jobs: designers, technicians, experts, educators,… Even when we talk about 3D printing taking away construction jobs: it might change construction jobs as we know it, but skilled technicians will still be required.

What is certain is that the skill set required is changing, and that the ways we approach jobs is too. 3D printing is a driver of change more than a threat, and is participating in the large reshaping of the workforce that is taking place today.

To quote the WEF report again:

“So far, the debate on these transformations has been sharply polarized between those who foresee limitless new opportunities and those that foresee a massive dislocation of jobs. In fact, the reality is likely to be highly specific to the industry, region and occupation in question and the ability of various stakeholders to successfully manage change.”

The one skill that we know will be needed from everyone in the workforce and in the policy makers is: adaptability.

What about you ? Are you ready for the fourth industrial revolution ? Is it a threat for you or your business ?

Talk about it in the comments below and feel free to share this article on the social platforms.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook