Spécifications techniques des matériaux d'impression 3D

Tout ce que vous devez savoir sur nos matériaux d'impression 3D et de découpe laser au même endroit !

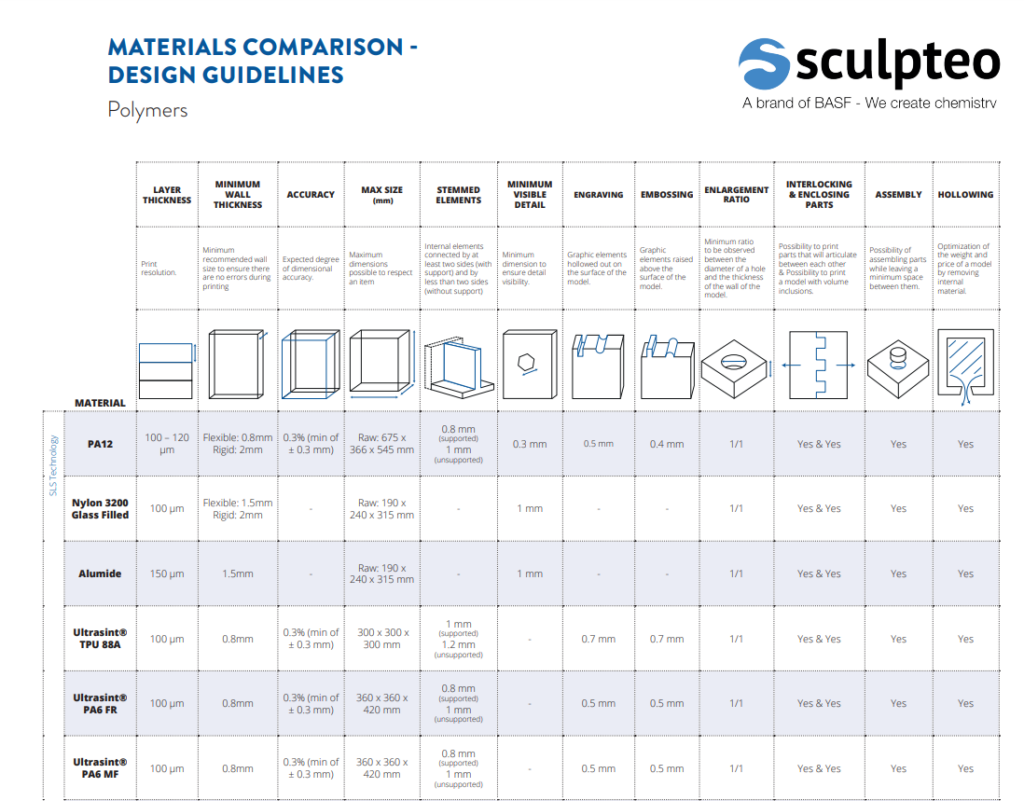

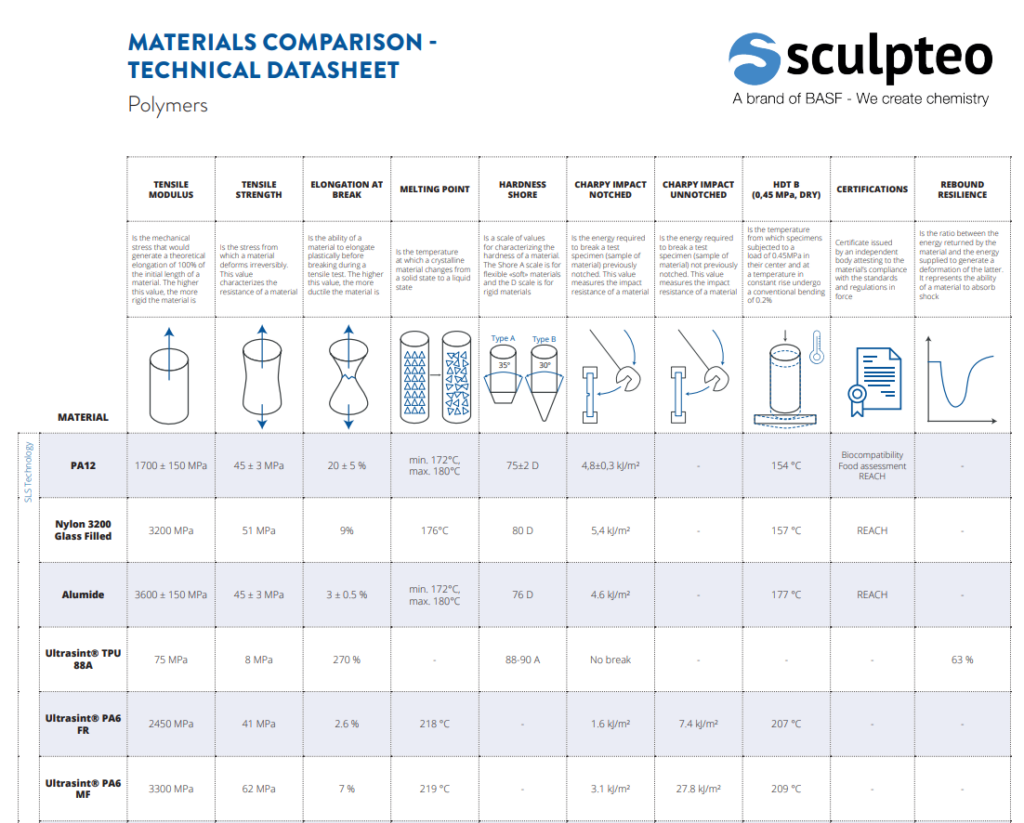

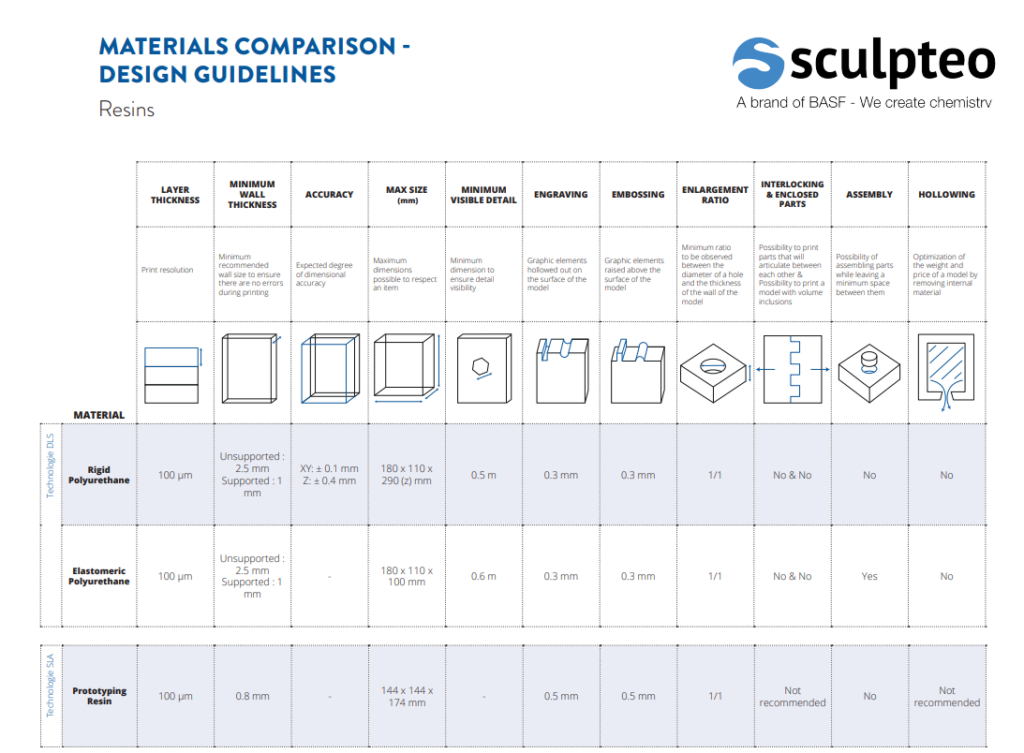

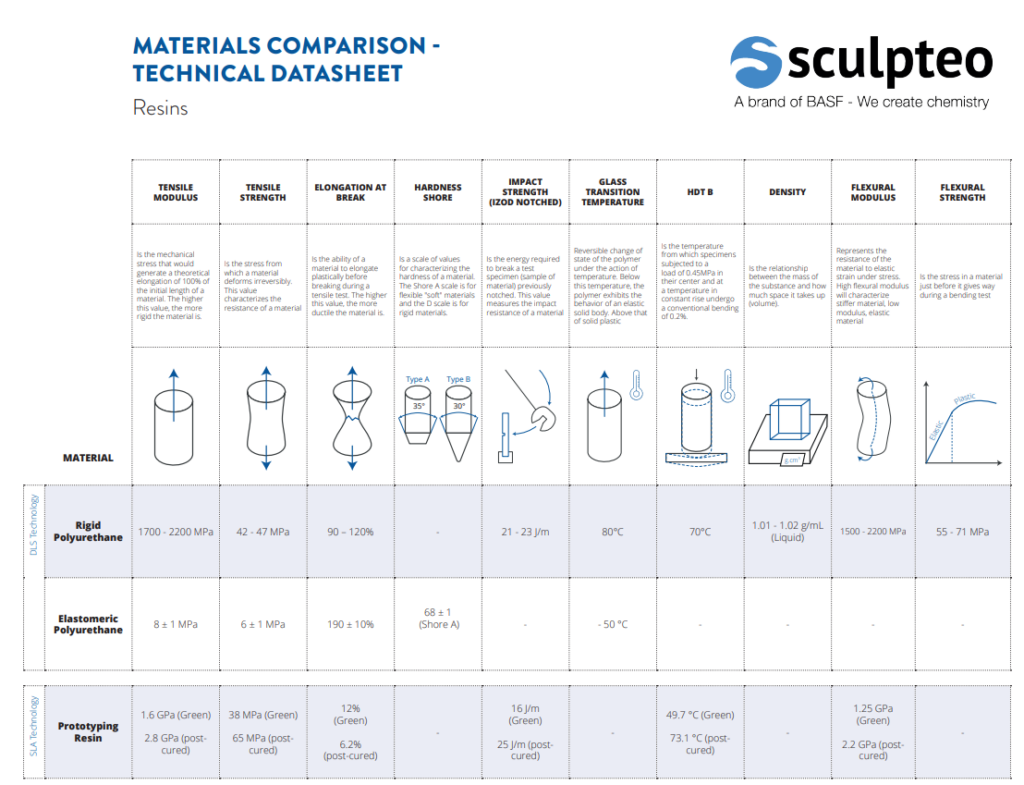

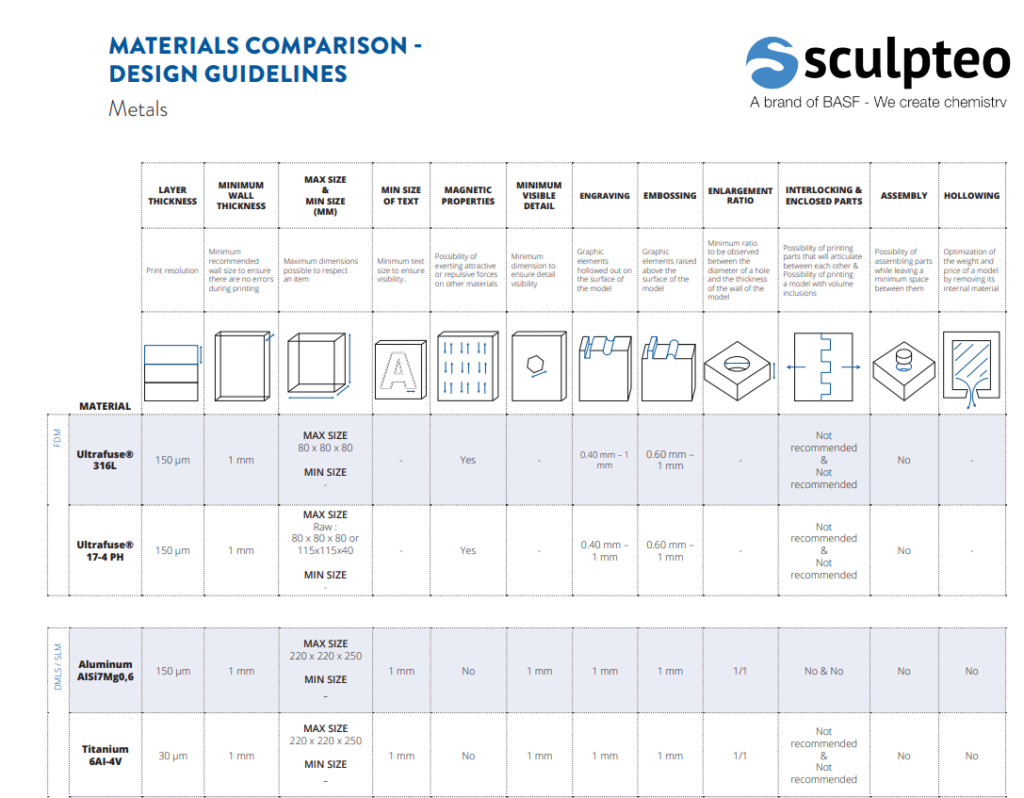

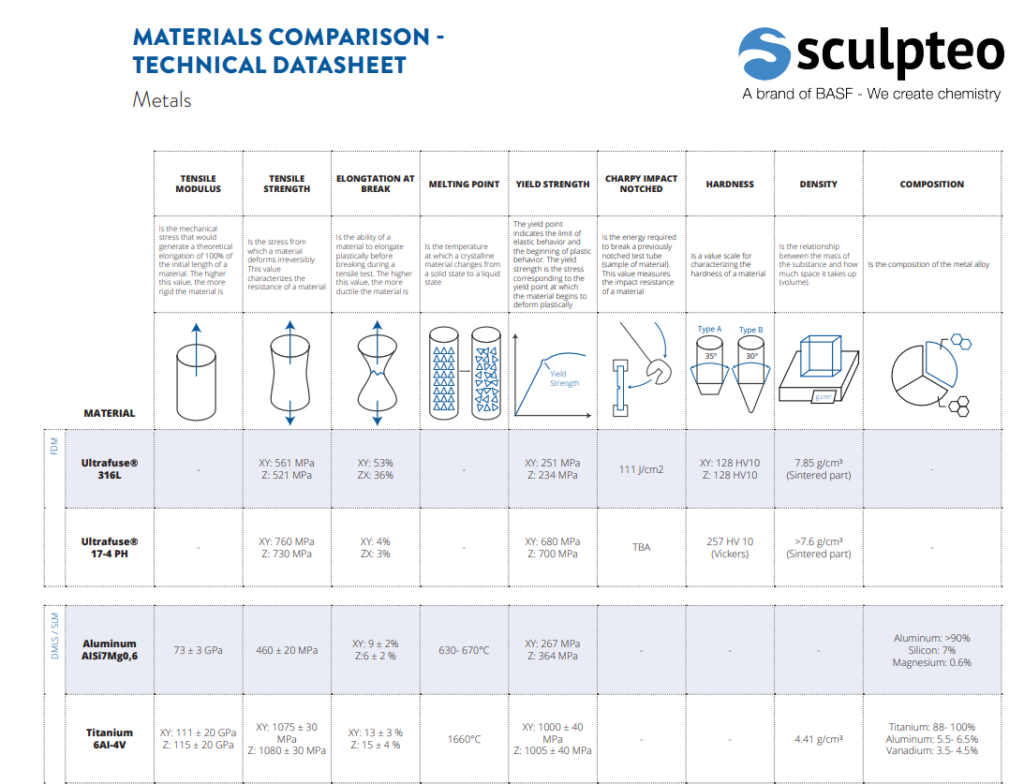

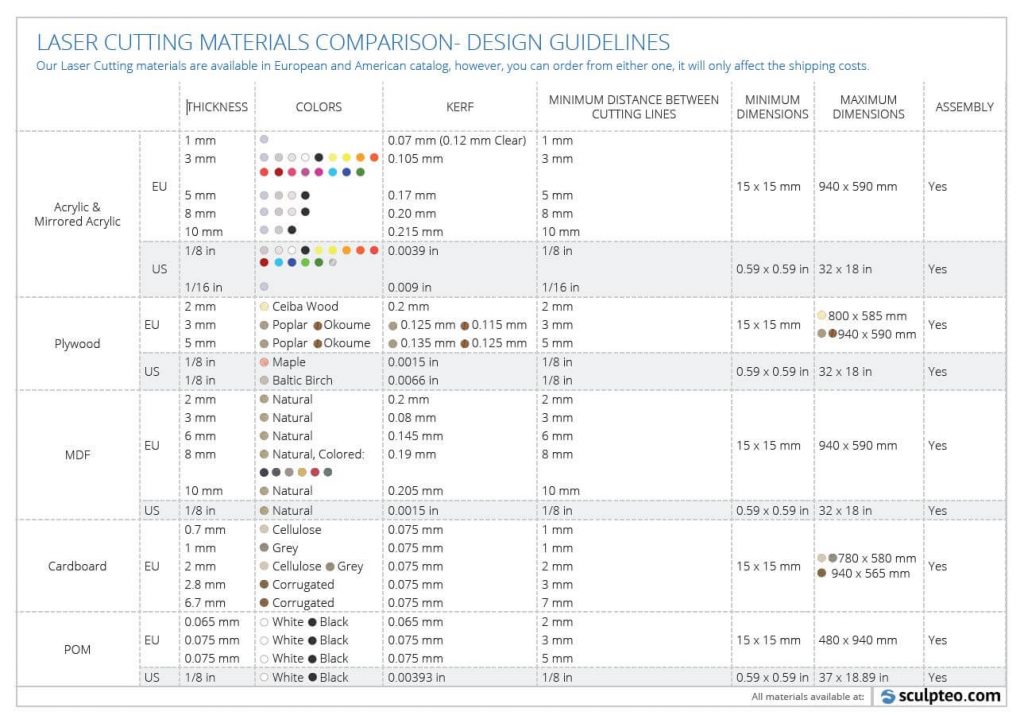

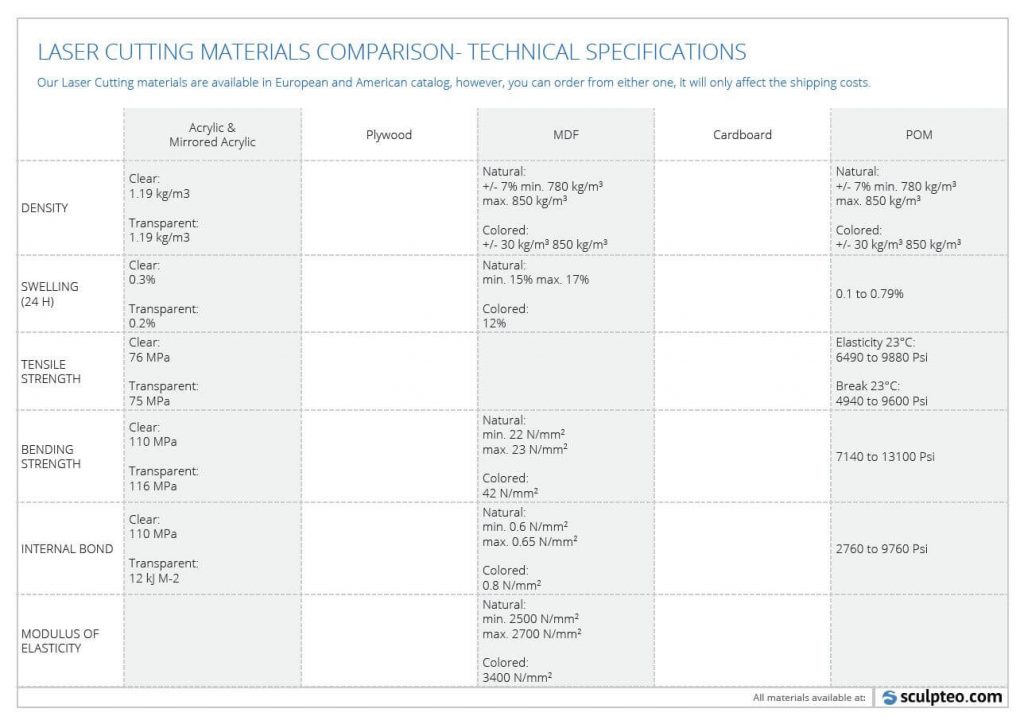

Retrouvez toutes les règles de design à suivre pour chaque matériau, ainsi que ses spécificités techniques. Vous recherchez la documentation des matériaux? Toutes les fiches techniques sont ici.

Prêt à faire de vos modèles 3D une réalité ?

Chargez votre fichier 3D, sélectionnez votre matériaux et vos options de finition, laissez notre service d’impression 3D professionnel s’occuper du reste. Vous receverez vos pièces en quelques jours. Commencez dès maintenant à imprimer vos prototypes en 3D !

Connexion avec Google

Connexion avec Google Connexion avec Facebook

Connexion avec Facebook