Top 10 of the best laser cutters: Our guide for successful laser cutting

Posted By Marianna Papageorgiou on Jan 17, 2018 | 0 comments

Laser Cutting is great technology that enables the creation of many applications, from outstanding business cards and modern school kits, to birdhouses and Nespresso capsule holders. But along the creation of a laser cut project, many questions arise. Which material should I use to fit better my projects? Which design software is better suited? How should I design for this technology? And most important of all.. Which Laser Cutter to use?

We know that the selection of the right laser cutter can be tough and depends on many factors. In this blog post, we will try to solve all of your questions about how you can successfully laser cut. We will also provide you some guidance if you are interested in getting to know more about the laser cutters that are available on the market and their features. You can also learn what you can achieve with our Laser Cutting service, and how it can be the best solution for your projects!

What is Laser Cutting?

Laser cutting is a digital subtractive fabrication technology that uses a laser to cut materials. When a machine engraves and cuts with a laser, it uses the technique based on thermal material removal. The high-power laser is projected in a small area of material, resulting in the heating of the material, melting and vaporizing it. The whole procedure is directed by a computer, which indicates the path that the laser beam will follow to cut the material. The laser beam is not touching the material, fact that leads to a high level of precision. The material used is usually a flat material (two-dimensional material with small thickness).

Laser engraving and cutting are widely used in many engineering applications, educational projects, creation of decorative objects. Compared to other fabrication techniques, it is relatively economical and it is usually prefered for the creation of small batches that require a high level of detail. The laser cutters are also used commercially for industrial applications and by hobbyists.

Laser Cutters: The best selection of the market

There is a wide range of laser cutters available on the market today. Each one comes with different features, can process different materials, has different cutting speed and of course it is addressed to different budgets. Apart from the traditional Laser Cutters, multifunctional Laser Cutters begin to gain popularity. Read our selection of the best laser cutters to install, from desktop to industrial ones, to see which one fits you better:

Desktop Laser Cutters

Laser cutter #1: FABOOL Laser Mini

FABOOL Laser Mini is a great option to consider when deciding of buying your first laser cutter. You can purchase this ready-to-assemble desktop laser machine and engraver for only $598. It processes a wide range of materials, from wood and leather, to food and plastic. Its free all-in-one software, makes it user-friendly and ready to be used by all kinds of users. It is mainly addressed to hobbyists, or designers who want to create their projects in house, and it can also be used for educational purposes.

Laser cutter #2: Glowforge

Glowforge is a wireless desktop 3D laser printer that stores your 3D files & data on a cloud. Its UI (User Interface) makes it easy to handle and allows everyone to create its own laser cut project. Whether you use a simple 3D modeling program or a more advanced one, with this laser machine you can cut the material in the final form you want.

With Glowforge, you can laser cut and laser engrave many materials, like fabric, wood, leather and more. If you want to visualize how your laser cut products will look like, you can check their gallery for some inspiration.

Laser cutter #3: Mr.Beam

Mr. Beam is an easy-to-use desktop laser cutter which is mobile ready. It is mainly addressed to people with no prior experience in the field such as hobbyists, artists, or people who want to get familiar with the technology. You can create your design using any 3D modeling software (like Illustrator, Corel, Inkscape etc..), or use any of the design software that are integrated into the Mr. Beam library.

Industrial Laser Cutters

Laser cutter #4: Orion Motor Tech

The Orion Motor Tech Auxiliary Rotary Device is an industrial-scale CO2 laser cutter and laser engraver. Even if it’s not a metal engraver, it can process a variety of materials, from bamboo and aluminum to marble and cork. It is a 50W CO2 laser machine and its working platform comes at the size of 1020 x 650 x 550 mm. If you want to purchase it, you can check out more about its characteristics here.

Laser cutter #5: Mophorn Laser Engraving Machine

The Mophorn Laser Engraving Machine is an industrial 80W CO2 laser cutter that costs $3,000 This engraving machine supports CoreDraw, Auto CAD and other advanced 3D modeling software. Moreover, it supports multiple graphic formats, such as .HPGL, .BMP, .GIF, .JPG, .JPEG, .DXF, .DST and .AI. It is a choice prefered by many industries, such as the toy industry, the shoe industry, etc.. The maximum cutting size is 700 x 500mm and its laser wattage is 80W.

Laser cutter #6: TEN-HIGH Engraving Cutting Machine

TEN-HIGH is an industrial CO2 laser cutting machine, cheaper than the previous ones, and working with lower laser power (40W). It costs $1,430 and its maximum cutting size is 300x400mm. It can process a wide range of materials, yet not metal ones. It uses an USB interface, and unlike the other machines, it only supports CorelDRAW software. If you are looking for more information and how to purchase it, you can visit this page.

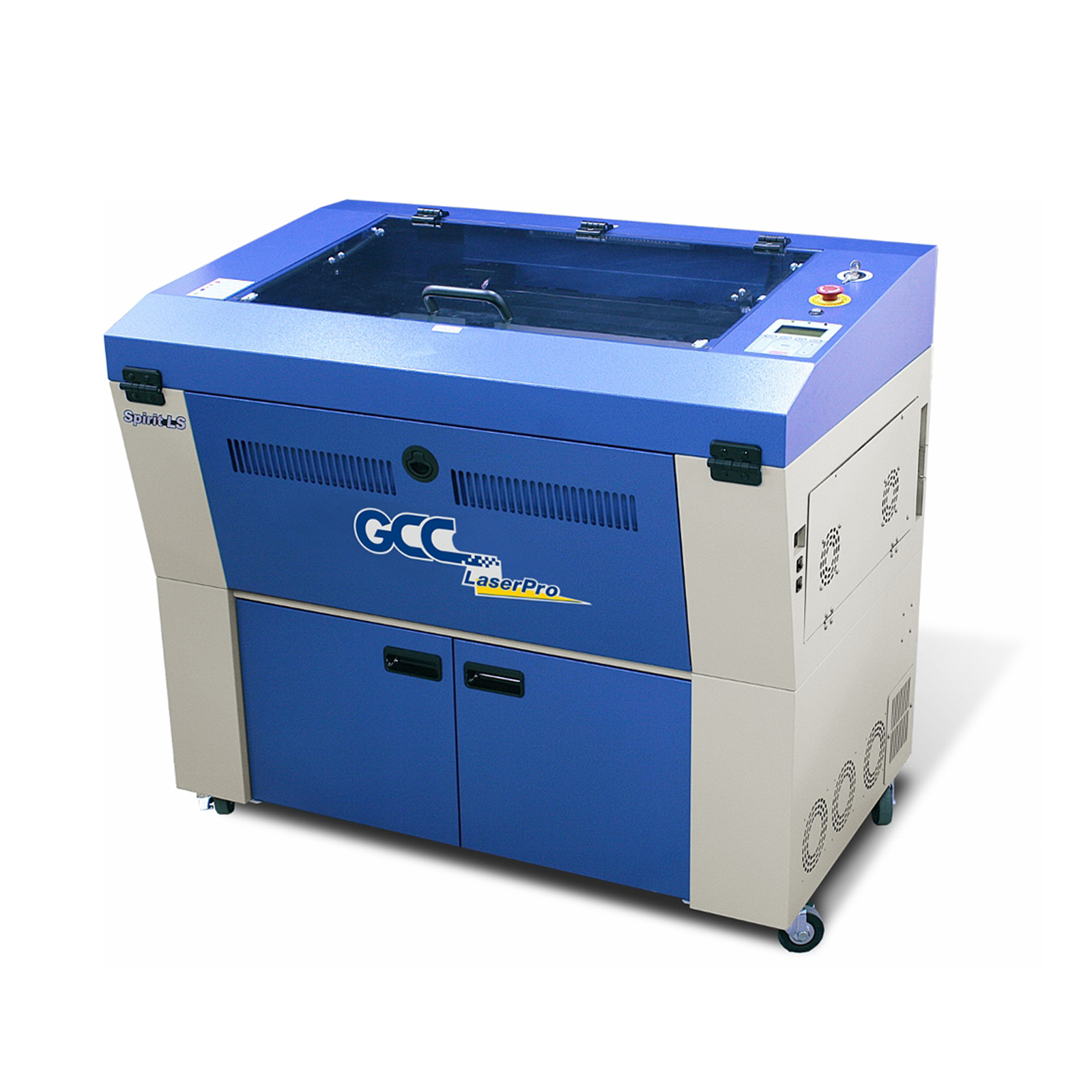

Laser cutter #7: Spirit GLS

The Laser Cutter we use at Sculpteo is the “Spirit GLS” from the award-winning GCC LaserPro Spirit line of laser engravers. Since its introduction to the market of manufacturing, the machine has received multiple worldwide awards. In addition, it is a laser cutter that is equipped with sensible upgrades to further boost overall usability.

We choose that high-quality laser cutter because we always try to provide you the best customer experience and receive accurate and quality products. At Sculpteo, we acquire all the necessary technical knowledge and expertise about how to handle the Spirit GLS machine. So, instead of purchasing one of your own, you can receive fast and easy your laser cut parts by ordering them through our online Laser Cutting Service.

Combination of Laser Cutters and 3D printers

Multipurpose fabrication is the next big trend in the manufacturing industry. Technology, has enabled us to include multiple functionalities in just one machine! A single machine can nowadays perform at the same time as 3D printer, Laser Cutter, Laser Engraver and CNC (computer numerical control) milling machine. Let’s see which are these machines on the market and which are the best laser cutter features!

Laser cutter #8: ZMorph VX

ZMorph VX is an exceptional machine. It is a machine that can transform into a mini-factory that integrates a 3D printer, a laser cutter, a laser engraver and a CNC machine. With this machine, you can enjoy the freedom of choice or combination of all fabrication methods. For 3D printing, it processes many types of plastic, among others ABS, PLA, flexible materials etc.. For CNC cutting and engraving it can work with all kinds of wood, acrylic, glass, copper laminates (for PCBs) and many other materials. As laser cutter, it works with all types of wood, leather etc.. But ZMorph VX doesn’t stop there! It can also process chocolate, cookie dough, cream cheese, frosting and ceramics!

Laser cutter #9: Faktotum

Faktotum can be considered as an all-in-one laser printer as it can perform many functions. Apart from its main functionality as 3D printer, it comes with a milling head and a laser head. It cuts or 3D mills metals and woods and it works with the laser for rapid prototyping. You can discover more about this personal fabricator here.

Laser cutter #10: BoXZY

BoXZY is not just a 3D printer. You can use this machine as 3D printer or as CNC machine or as a laser cutter. You can purchase this multifunctional machine at the same price as a normal 3D printer, but with many more tools. BoXZY is used for many purposes. Apart from educational purposes it is used by engineers and artists who want to materialize their work and make a craft with it. In order to get an idea of what this machine can do, you can visit the product gallery.

Should you buy a Laser Cutter or use Laser Cutting Services?

Regardless if the Laser Cutter is a desktop one, an industrial one or multifunctional, it is definitely an expensive purchase. Aside from the cost of the machine itself and any upgrading of it, comes the additional cost of maintenance, the cost of the materials, the cost of the electrical power consumed, the cost of time you spend learning to operate the machine and cut your materials properly. What could you do in order to avoid all these additional costs that are arising quite often? A safe solution to create your laser cut project would be to use a Laser Cutting service!

Using an online service to create your projects, you don’t have to worry about all these expenses. You are guaranteed that the part you ordered will be delivered to you on time and in the proper quality.

Sculpteo is well-known as the best online 3D printing service, but is not just that. Sculpteo provides Laser Cutting services too. More than 60 variations for cut or engrave materials in different colors and thicknesses! You can discover all our available materials and choose the one that fits your project better! Once you upload your file on our platform, our production algorithm analyzes the amount of material you need and how long the cutting will take. This provides you more autonomy in the cut settings, transparency of the price change and faster delivery of your parts.

Together with Sculpteo’s expertise in design and manufacturing, you can also work with Sculpteo Studio. Our professional industrial designers will, according to your needs, provide you design, consulting and training services, that will help you achieve the best result for your project. Do not hesitate to contact us if you want to start a design collaboration with Sculpteo Studio.

Laser Cutter Materials

A wide range of materials can be laser cut with high precision, where traditional manufacturing methods prove to be inefficient. Typical materials processed by the laser cutters are: acrylic, plywood, MDF, cardboard, POM, aluminum, steel, stainless steel, leather etc..

Laser cutter materials can be found in a big variety of thicknesses, which influences their rigidity and mechanical properties. Depending on the material and its thickness, it is suitable for different purposes. We prepared this guide, which will be proven to be very useful if you want to get familiar with which materials fit better each laser cut application.

Our design tips for a successful Laser Cut

Even though it is easy to engrave or cut with this technology, you might appreciate a few tips that will help you achieve a successful result! For example, are you aware of the living hinges and how to design them? Do you know how to choose the right 3D modeling software for preparing your model to be laser cut? Are you familiar with how to fold laser cut metal sheets without machines or tooling?

Laser Cut and Laser Engrave with our Tutorials

In order to laser cut or engrave an object, you’ll need a vectorial file. Thanks to our years of expertise in design and manufacturing, we have created some tutorials to help you successfully prepare the file that will be sent to the laser cutters. Through our Tutorials, you can learn how to handle a wide range of 3D modeling software such as Adobe Illustrator, SketchUp, Inkscape, Slicer for Fusion 360 and Fusion 360. These tutorials, aim to teach beginners how to design a basic model, how to detect and avoid the errors that can arise during the 3D modelling process and how to export the 3D files according to the necessities of the technology. If there is a particular tutorial you’d like to see added, do not hesitate to contact us.

On the other hand, if you are not confident in putting up a design, you can always purchase a 3D file on one the best marketplaces to find laser cut models. It is easier and less time-consuming. The next step you have to follow afterwards is to upload the file on our online platform and we will deliver you the parts so you can assemble them!

Supported file formats for Laser Cutting

It is recommended that you save your 3D file in .SVG format, as it gives the best results. However, we remind you that at Sculpteo online Service, we accept and process many more types of file formats, such as: .AI (v9), .CDR (v7-X4), .DXF, .EPS, .PDF, .RAR, .ZIP and of course .SVG

In order to enrich your knowledge in the field, we suggest you to have a look at our ebook about Laser Cutting. You can find plenty of information around this manufacturing field, from design guidelines to examples of industrial applications. You can download it for free here.

Laser Cutting or 3D Printing?

3D printing enables the creation of almost everything you dream about. Though, in some cases 3D printing is not the answer. Indeed, in some cases, Laser Cutting may be a better solution than any other manufacturing technique. This was the case of our customer iTabNav, which sells parts dedicated to the use of tablets on boats. For creating one of their accessories, they used our POM laser cut material because it was a better option than 3D Printing.

However, you can use more than one manufacturing technique for your projects. At Sculpteo, we created furniture using 3D printing and laser cutting for a 3D print exhibition in Lyon! Also, this drone was created by using both laser cutting and 3D printing! Each technology has its own benefits, and the combination of both provides an excellent and complete result.

We hope this little guide helped you learn more on the laser cutter options that are available right now, select the right materials and using properly our laser cutting service! If you want to gain more knowledge about Laser technologies, you can check out here all our previous articles around this topic.

If you feel inspired enough to create your next project, all you have to do is to upload your file here, and we will take care of the rest!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook