Which Laser Cutting Material For Which Application?

Posted By Eole Recrosio on Jan 18, 2017 | 0 comments

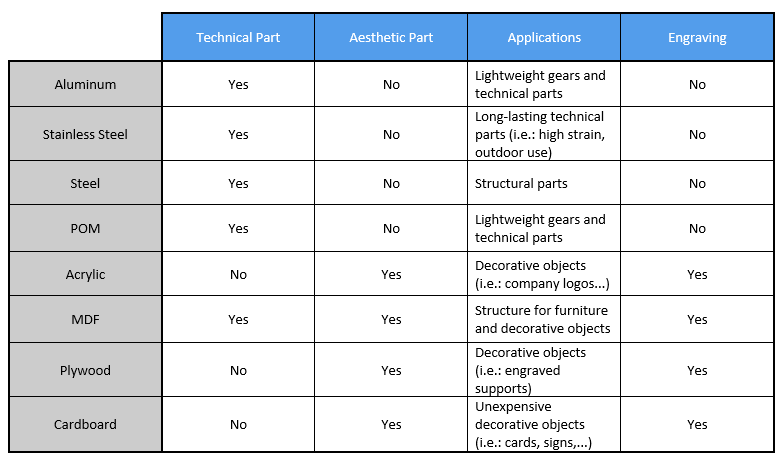

For a few weeks now, we provide 8 different materials for laser cutting on our online platform, available in various thicknesses and colors. From Metals to Cardboard, our materials offer a wide variety of uses and applications for your laser cutting projects. Not all materials are designed for aesthetic uses and, of course, some of them are especially made for technical parts. Discover this guide of how to use our laser cutting materials. It will be an opportunity to get familiar with our most recently added laser cut materials: our laser cut metals, aluminum, stainless steel and raw steel.

Our Laser Cutting Metals

From the time we launched our laser cutting service, our clients expressed a high demand for metal laser cutting. It is now possible to laser cut through our online laser cutting service in aluminum, stainless steel and steel.

Metal laser cut parts are ideal for technical parts

These metal are very resistant, and ideal for technical, mechanical parts.

But they are not to be used for aesthetic parts

They are not, however, destined to be used for aesthetic purposes, since they come without any surface finish, and are often marked.

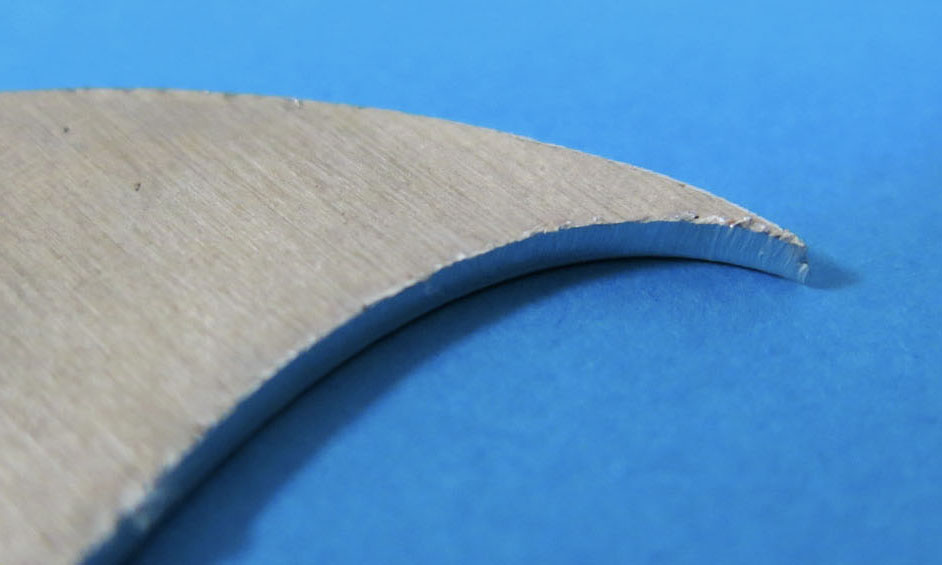

Scratches on the surface of an aluminum laser cut part

Why these marks on metal laser cut parts?

- For metal laser cutting, the laser initiates before cutting or engraving, and leaves a mark on the material. This is especially problematic for details smaller than the thickness of the material

- When it comes to raw steel, the marks also come from its corrosion speed: its surface might rust in surface

When the laser hits the surface, it creates splashes, especially when creating small holes

How to avoid these marks?

You can limit the marks by avoiding details inside the part, especially details that are smaller than the thickness of the material. The metals on our platform are available in 1 mm, 2 mm or 3 mm. For example, for a stainless steel part made with the thickness of 3 mm, a whole in the part shouldn’t be smaller than 3 mm of diameter.

You can also apply an additional surface finish on your parts after receiving them (painting, polishing…).

These techniques might not avoid all the marks and stains on your metal laser cut parts, but will reduce them.

Traces of corrosion on raw steel. It is only aesthetic and doesn’t alter the mechanical properties

What about laser engraving metal parts?

Laser engraving is the same: it won’t produce an aesthetic result on metal parts. The engraving is very light, and sometimes not very visible. It can be used to mark the parts for later post-processes (machining,…), or to add serial numbers.

Aluminum part marked for machining

How to choose between the 3 metal laser cutting options?

To sum up:

- Aluminum has the best weight/strength ratio

- Stainless steel is most resistant to rust and harsh condition

- Raw steel is very strong but needs an additional surface finish

Edges of metal laser cut parts can be sharp

Aluminum and Its Applications

Advantage

Aluminum is the metal with the best weight / strength ratio. That means that the aluminum parts are very interesting where weight is a concern.

Aspect

The aspect of the aluminum is shiny but the surface can be scratched and the edges slightly sharp.

Possible finishes

Remember that in addition to machining possibilities (sawing, drilling, folding…) the aluminum can be sanded, polished, painted and silkscreened to become more aesthetic.

Possible applications

We can find applications in transportation, automotive or aerospace industries for cogwheels or gears.

At Sculpteo, we used aluminum in the Sculpteo Bike project for the crank and brake discs. You don’t know what is the Sculpteo Bike Project? Visit our blog article on the first digitally manufactured bike!

To learn more about the characteristics and uses of the aluminum for laser cutting, you can visit the dedicated material page.

How to Use Stainless Steel

Advantage

This engineering material is strong and has the particularity to resist to corrosion. The mix of steel, nickel and chromium gives to that material the ability to resist to rust and harsh outdoor conditions.

Aspect

The surface of the stainless steel is brushed and slightly shiny. It is often scratched because of manipulations during the cutting process.

Possible finishes

It can be otherwise machined, sawed, drilled and also painted.

Possible applications

To continue, stainless steel is certainly one of the best-known materials among surgeons: it is indeed very easy to clean and to sterilize for hygienic safe uses.

Stainless steel has many applications:

- tools

- cutlery

- Surgical implants

- handle

- razor blades

However, our stainless steel is not designed for hygienic purposes and is not bio-compatible as it is.

Stainless steel was also used on the Sculpteo Bike Project for cogwheels that lead the bicycle chain. If you want to discover the Sculpteo bike project, you can check this article on the first digitally manufactured bike!

To learn more about this laser cutting material, you can visit the stainless steel material page.

A Structural Material: Raw Steel

Advantage

Our S235 Steel (S is for structural) can be used for any structure work and will resist to most of the mechanical and thermal stresses.

Aspect

Steel is darker than our two other materials and is the roughest one. Its surface can be scratched and tints very irregular.

Possible finishes

However, Steel is can be easily painted and covered to both protect it and improve its aesthetic aspect.

Possible applications

Among its applications, we can think of the architecture and building industry, but also into cars for structures.

To learn more about the capacities of the steel material for laser cutting, read our material page.

POM: An Engineering Thermoplastic For Technical Parts

Before laser cutting metals, we launched a unique and engineering material: POM, also called Delrin.

Two POM gears designed for technical uses

Another technical material

This engineering thermoplastic was our first laser cutting material entirely dedicated to technical uses. POM can endure large amounts of strain and friction. It is very resistant and experiences very little shrinkage. Moreover, POM is weatherproof, waterproof and resistant to many solvents.

Not to be used for aesthetic purposes

Its white opaque surface is not very aesthetic and often covered by little scratches but its mechanical properties are unequaled for a plastic.

Can POM parts be laser engraved?

As for metal, engraving on POM isn’t very aesthetic. It will come out as very light, sometimes barely visible. It can be used for serial numbers and post-processing marks.

To learn about our POM material, you can visit our dedicated material page.

Decorative Acrylics For Your Laser Cutting Projects

A large laser cut acrylic S from Sculpteo

Many colors for your aesthetic projects

When it comes the time of aesthetic objects and surfaces, we recommend using acrylic.

These Plexiglas sheets are covered by foil during the laser cutting process, that protects the surface from scratches. Available in many colors from opaque to clear, acrylic is a beautiful material for decorative objects, company signs, and LED covers thanks to our diffuse acrylic.

To be avoided for technical parts

The acrylics have limited technical applications and are mostly used for decorative objects.

To discover the 85 acrylic possibilities (with different colors and thicknesses), please visit our material page.

MDF: Technical and Decorative Wood

A MDF box created by our designers with a living hinge

Laser cutting wood for resistant and aesthetic parts

Laser cutting is also fitted for woods such as MDF. Medium-Density Fiberboard (MDF) is our wood engineering material. It is relatively resistant thanks to wax and a resin binder mixed with wood fibers.

Aspect:

With laser cutting, the aspect of MDF parts is very good, especially thanks to our several color choices. The only thing to keep in mind is that the sides of the part will be burnt.

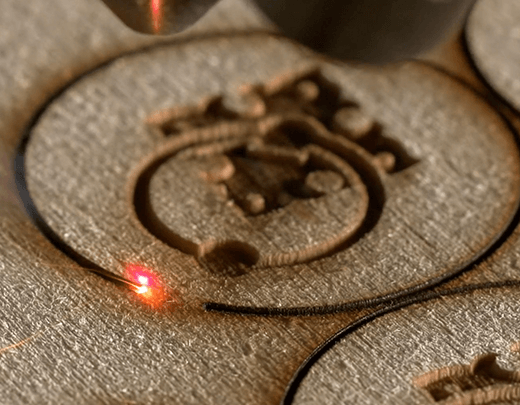

Laser engraving MDF

Laser engraving renders fairly well on MDF, but won’t achieve the precision and beauty that you can achieve with our next material, plywood.

Possible applications

The main application for MDF is in the furniture industry. It is often used as a structure for furniture and drawers. At Sculpteo, we used MDF to build the base of a design lamp.

MDF can be used for both technical and decorative purposes but we recommend to check the material technical specificities on the material page to be sure that it fits your project.

MDF is available in 7 tints (natural, black, gray, light gray, yellow, green and red) and 4 thickness up to 10 mm! You can learn more about it on our material page.

A Decorative Wood: Plywood for laser cutting

A close view of a piece of plywood being laser engraved

Advantages and possible applications

Our last wood material is Plywood, available in two varieties: Poplar and Okoumé. This type of wood can serve many purposes from structure to aesthetic objects. It is often used by builders, designers or artists for its mechanical resistance (structures, buildings), its flexibility (furniture), its aesthetic beauty, its water resistance and its lightness. It is better used for decorative purposes than for technical parts.

Aspect and laser engraving on plywood:

Our plywood retains its natural grain, which makes each part unique. Laser engraving renders extremely well on both our plywoods.

To learn more and use plywood for your laser cutting projects, please visit our material page and upload a design!

The Cheapest and Multi-Purpose Material: Cardboard

Some laser cut business card in cardboard

Finally, we keep the best-known material for the end: cardboard. This paper-like material has various properties depending on how it has been manufactured. At Sculpteo, we offer 3 types of cardboard:

- Corrugated cardboard (simple and double)

- Gray compact cardboard

- Cellulose compact cardboard

Possible Applications

Each of these materials is used for digital printing, packaging prototypes manufacture, modelisation (shapes, drawings), and more.

Cardboard is exclusively used for decorative objects as it is not weather resistant.

Aspect and laser engraving for cardboard

Laser engraving renders very well on cardboard. Line engraving is so thin it looks like print.

Read this article to learn how to make memorable business cards with laser cut cardboard.

To learn more about our engraving service, you can visit the dedicated page on our website.

To discover all the possibilities of cardboard, please visit our material page.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook