How we used 3D printing to create furniture along with laser cutting

Posted By Amandine Richardot on Aug 30, 2017 | 0 comments

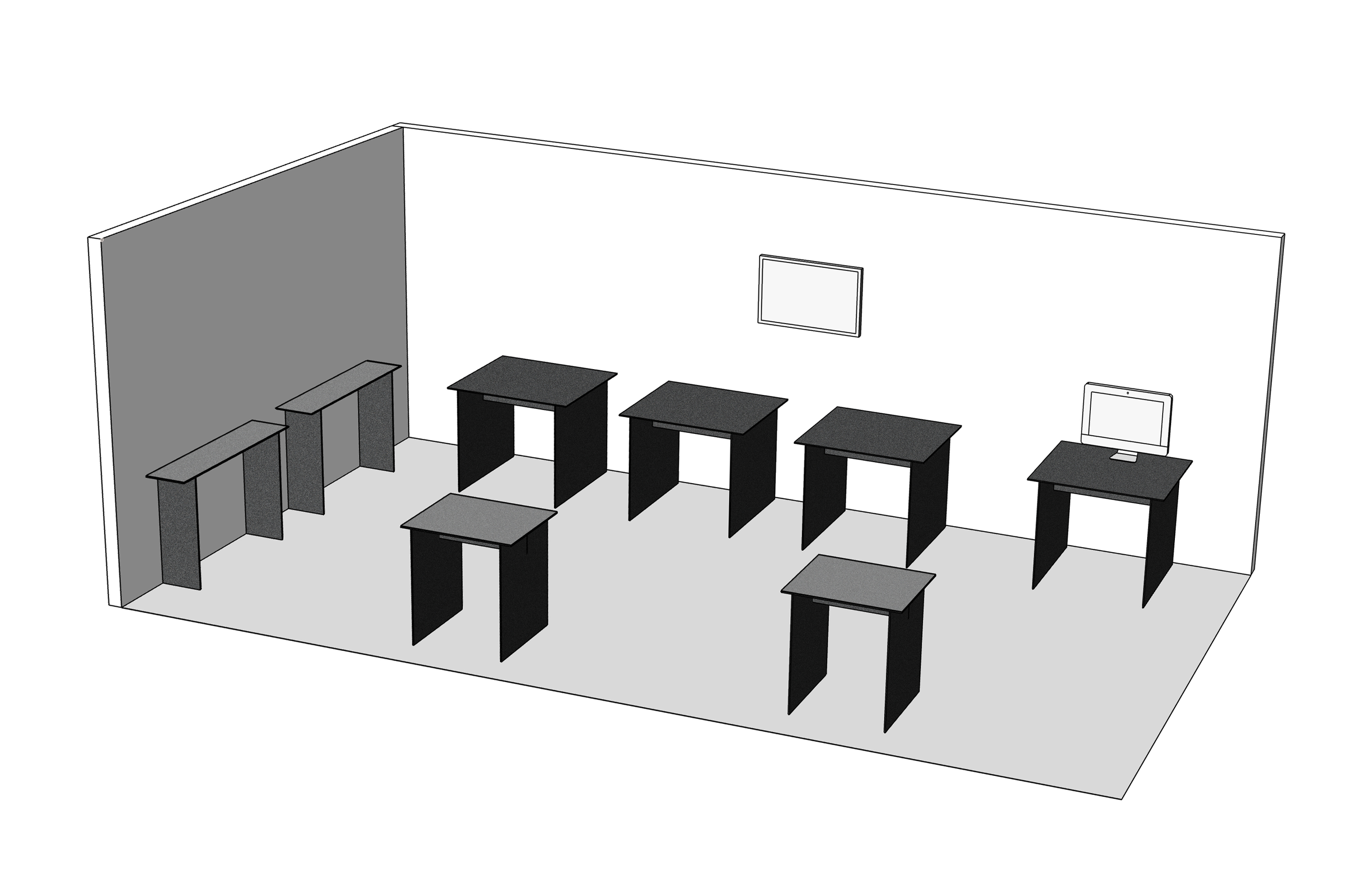

Last June, we were proud to take part in the 3D print exhibition in Lyon, along with the most influential companies from this field. For that occasion, we asked our designers to build furniture for our booth, using our digital manufacturing techniques: 3D printing and laser cutting. We wanted to show that these technologies could both be used for real-life applications, to build useful objects, with large dimensions. Discover now how we created furniture using 3D printing and laser cutting!

Creating furniture with 3D printing for an exhibition

Our designers had to create furniture to show our different 3D printed objects, showing our wide range of 3D printing materials and technologies. Why designing them ourselves? Actually, we needed to create 3D printed furniture that we could make evolve for each event, with dimensions changing each time (due to the booths dimensions that change for each event, and to the changes in terms of products shown).

Also, we needed these 3D printed tables to be easy to transport, with easy assembly and disassembly processes.

Moreover, we wanted to show what our amazing technologies can produce: introducing everyone to the great possibilities that digital manufacturing can offer, allowing to create furniture for instance.

Here’s what we came out with:

And here’s what our digitally manufactured tables made with 3D printing and laser cutting looked like in real life:

Now, discover how we made them!

How we conceived these digitally manufactured tables

3D printing furniture is great, but we wanted to use our digital manufacturing techniques in the smartest way possible, as we did when we created a bike with 3D printing and laser cutting. Combining both laser cutting and additive manufacturing is a way to optimize your whole production process, to create clever structures, at a lower cost. Indeed, instead of 3D printing large plane surfaces, why not laser cut them, which will be cheaper?

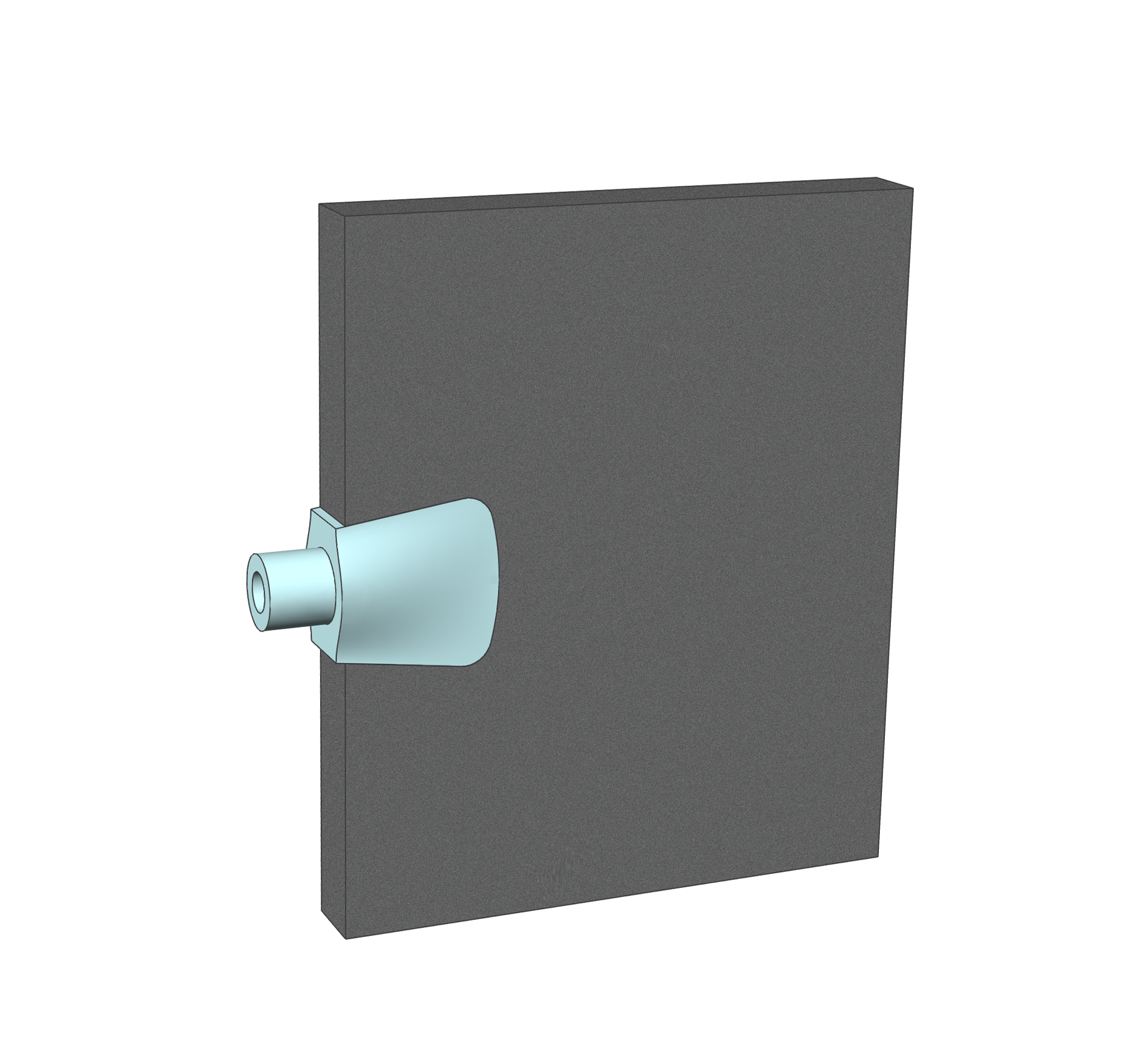

That’s why we designed these tables made of large laser cut black boards, in MDF material (Medium-Density Fibreboard), with 3D printed custom-made dovetail joints. Here’s how the assembly process works:

Here’s how the boards are assembled together, with custom-made 3D printed dovetail joints, in white Nylon (PA12):

The tables are also assembled using some metal screws.

Why we used laser cutting for these tables

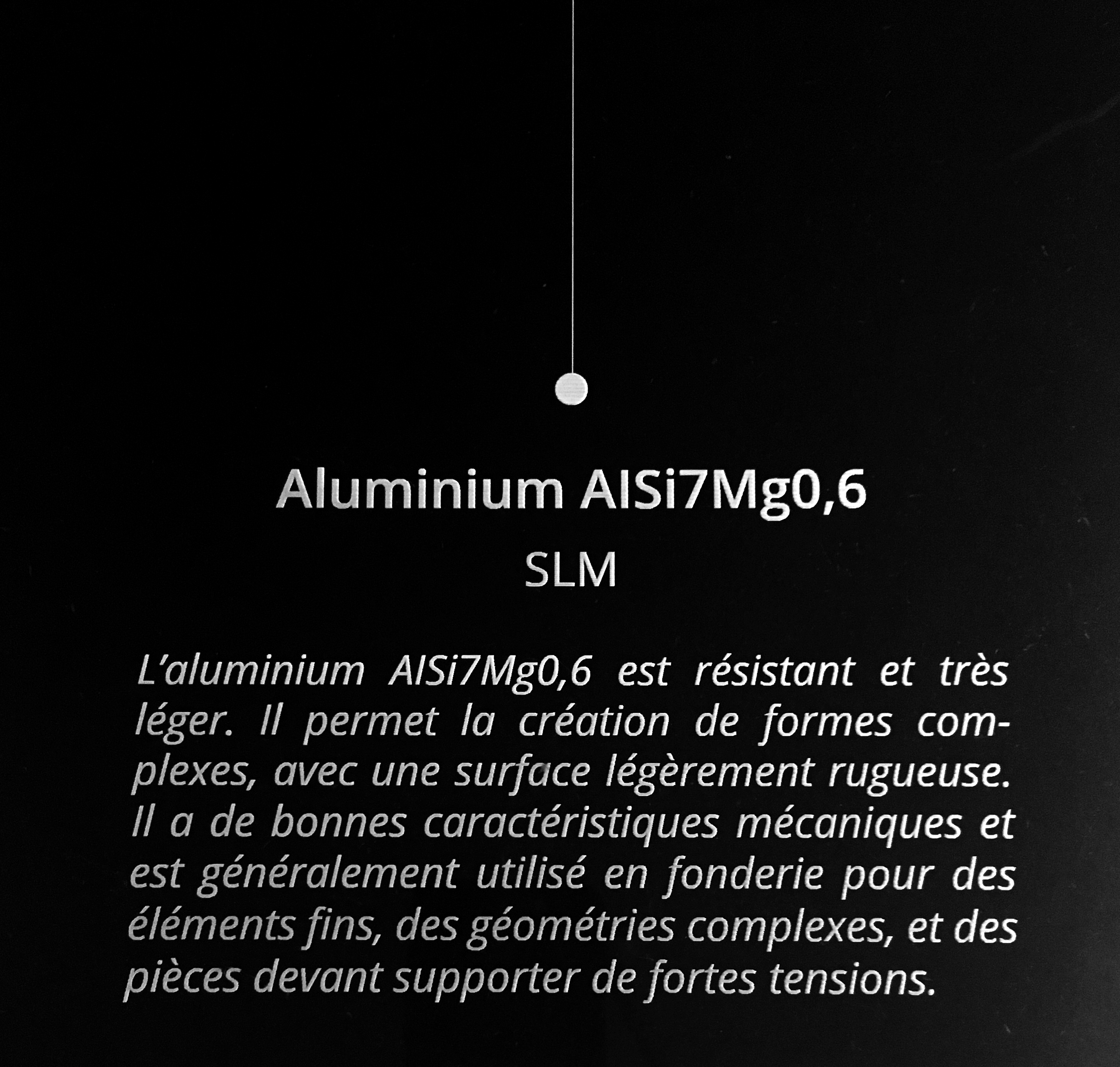

Laser cutting is a truly relevant technology to manufacture furniture, and especially tables. Indeed, it’s interesting in terms of cost and allows to manufacture large parts quickly. Also, we used MDF material (Medium-Density Fibreboard), which is a material that remains perfectly plane even on big surfaces. We chose the black version, which is mass-colored, for aesthetic purposes.

The laser cutting technology offers great manufacturing possibilities since it’s an easy and fast production tool. Indeed, in only one digital operation, you can choose the dimensions of your objects, insert some details (to insert the dovetail joints for instance), and then directly get your laser cut part. Moreover, it allows high precision.

We also combined the use of laser cutting and laser engraving to put some special text on the tables. Since we wanted to use them again, we needed to have the text written on parts that we could easily remove and replace by new boards with some other text. As a result, we decided to laser cut translucent Acrylic boards, to put on top of the tables, and to engrave them. Once again, laser cutting allowed us to go really fast in terms of production.

Here’s how our tables looked like with the engraved laser cut acrylic boards on top:

And here’s a closer look at our engraved parts:

Why we used 3D printing for furniture

Using 3D printing for furniture is also really relevant. Indeed, by creating custom-made joining parts, we could make them extremely precise, fitting perfectly our laser cut parts. Nylon (PA12) allowed us to get particularly strong parts that could bring global resistance to our digitally manufactured furniture.

Since we could create small-size parts, in a 3D printing material which is inexpensive, it has also been quite cheap to 3D print them.

3D printed furniture is already getting big!

Indeed, creating 3D printed furniture is a major trend since this technology allows to create amazing designs, with custom-made objects that perfectly correspond to what you imagined.

For instance, you can create furniture made of complex structures that would be extremely hard to produce using traditional manufacturing techniques. Here are some amazing 3D printed furniture projects that will certainly inspire you to then create your own!

Scientists are also doing some research on how to create more easily 3D printed furniture, with crazy structures. For instance, the MIT Self-Assembly Lab, Steelcase, and the famous designer Christophe Guberan came up with a new process: Rapid Liquid printing, allowing to create customized furniture in matters of minutes. Learn more about this technique to manufacture 3D printed furniture now!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook