Home » Matériaux pour Impression 3D sur mesure » Technologie SLS » Ultrasint® TPU 88A

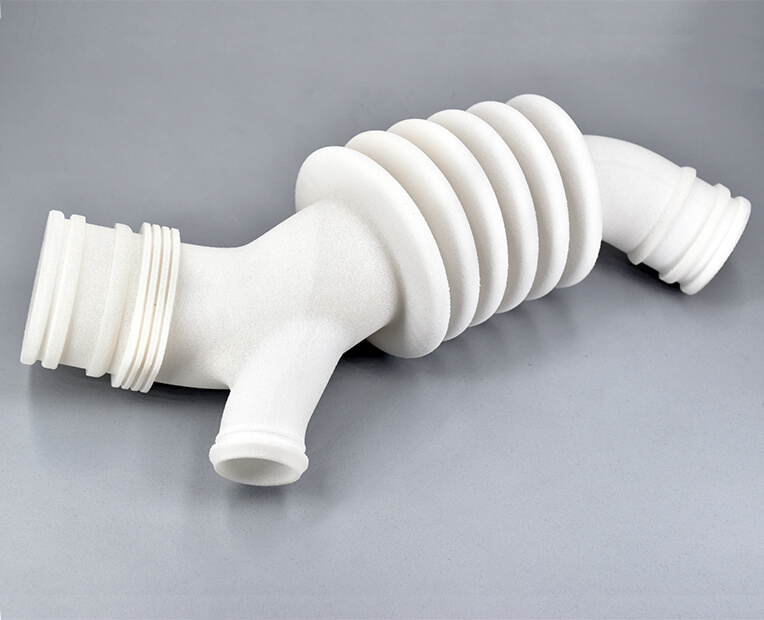

Ultrasint® TPU 88A Matériau d'impression 3D

Que ce soit pour votre processus de prototypage ou de production, profitez des avantages de ce matériau d'impression 3D. Flexible et résistant, découvrez le TPU imprimé par Frittage Sélectif par Laser.

Connexion avec Google

Connexion avec Google Connexion avec Facebook

Connexion avec Facebook