Minimum height and width details | Embossed : 0.7 mm

Engraved : 0.7 mm

|

| Ratio Depth / width | 1/1

|

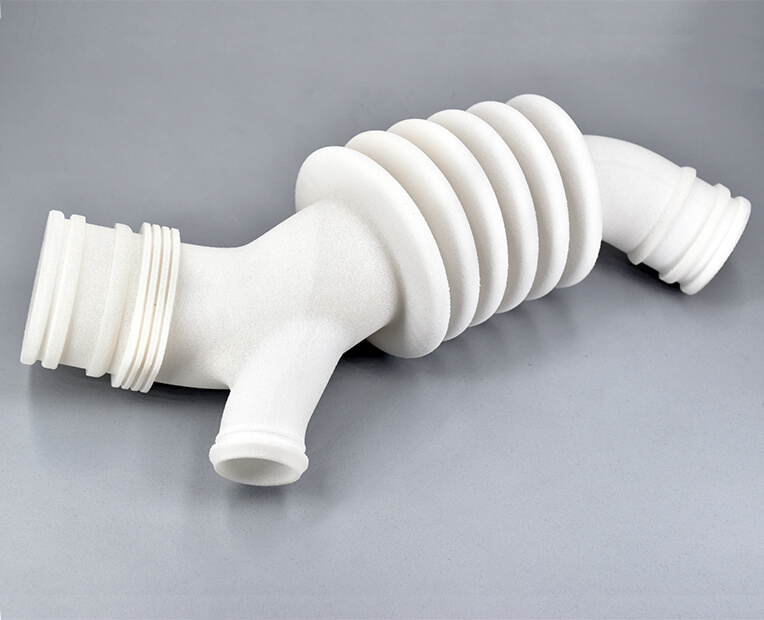

A detail’s minimum precision is mainly determined by the resolution of our 3D printers. However, during the cleaning process, a fine layer of detail can also be lost. In order for a detail and text to be visible we recommend following our recommended sizes at the very least.It’s possible that particularly fine embossings and engravings will not be visible, as the carving could get filled with excess powder that is later unable to be cleaned out. If an embossing or engraving is an essential part of your design we recommend making them as deep as possible. To ensure a better powder removal (thus a better detail visibility), the width of your details must be at least as big as depth.

| Minimum spacing between fixed walls | 0.5 mm |

| Minimum clearance between parts | 0.5 mm |

For a successful 3D print a minimum clearance between objects is required to allow excess material to be sand blown out. If this space is not left within the design, the object will be a solid. This is particularly important for articulated objects – as the space left between the walls will define the object’s ability to move.

Do not forget

Clearance should be at least 0.5 mm, however that is the minimum for small objects. Larger objects require more space between their parts. Our printer beds are heated during the process, and larger objects are heated for longer periods. A small space between large objects runs the risk of melting together as it remains under heat for a long period of time. In some other cases, holes should be added to allow us to drain for the excess powder material within the clearance.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook