CNC vs 3D Printing: A Comprehensive Comparison

CNC and 3D printing are two widely used manufacturing technologies, but how do they compare? In this article, we explore the differences between them both.

Login

If you have any trouble logging in to your account, contact us.

Sign Up

To start 3D printing or Laser Cutting, you'll need to create an account here. Once done, you'll be able to upload your files and get live quotes of yours parts

Already have an account? Log In

Home » 3D Learning Hub » 3D Printing Technologies » Explore the World of 3D Printing Technologies

In the realm of manufacturing and innovation, 3D printing technologies have emerged as a revolutionary force, transforming the way we create and produce objects. This article delves into the various aspects of 3D printing technologies, offering insights into their applications, advancements, and the future of this groundbreaking industry.

As a 3D printing service, we know that the variety of materials and technologies available on the market can be confusing for the consumer. That is why we decided to make this comprehensive guide.

The first step is the preparation just before printing, when you design a 3D file of the object you want to print. This 3D file can be created using CAD software , with a 3D scanner or simply downloaded from an online marketplace. Once you have checked that your 3D file is ready to be printed , you can proceed to the second step.

The second step is the actual printing process. First, you need to choose which material will best achieve the specific properties required for your object. The variety of materials used in 3D printing is very broad. It includes plastics, ceramics, resins, metals, sand, textiles, biomaterials, glass, food and even lunar dust! Most of these materials also allow for plenty of finishing options that enable you to achieve the precise design result you had in mind, and some others, like glass for example, are still being developed as 3D printing material and are not easily accessible yet.

The third step is the finishing process. This step requires specific skills and materials. When the object is first printed, often it cannot be directly used or delivered until it has been sanded, lacquered or painted to complete it as intended. If you need colored 3D printed parts a lot of post processing options are available.

The material chosen for the project will determine which printing methods are most suitable. Among these, the most commonly used techniques for each group of materials are described next.

There are several types of 3D printing technologies, each with its unique features and applications. This section explores common techniques such as Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and more. Understanding these methods is crucial for choosing the right technology for specific projects.

VAT PHOTOPOLYMERISATION

VAT Photopolymerization in additive manufacturing involves a vat of liquid photopolymer resin. A build platform descends, moving downward, and a laser beam shapes the resin, forming a layer. Subsequently, each resin layer must undergo curing with ultraviolet (UV) light. Motor-controlled mirrors direct the UV across the resin surface, causing it to harden. This method is suitable for high-precision, detailed parts but lacks the structural support of other additive manufacturing types. Parts produced may not be suitable for outdoor use due to potential degradation in color and mechanical properties when exposed to sunlight. Additionally, post-processing may be required to remove markings left by support structures. Popular vat photopolymerization 3D printing technologies include:

DLP technology is known for its speed in comparison to traditional 3D printing methods, as an entire layer can be cured simultaneously. This makes it particularly efficient for rapid prototyping and small-scale production. Additionally, DLP can produce objects with smooth surfaces and fine details, making it suitable for applications in jewelry, dentistry, and other industries where intricate designs are crucial.

MATERIAL JETTING

Material jetting deposits material in droplet form onto a surface, similar to inkjet printing but layer by layer on a build platform, then hardened by UV light. It is precise, allows for the use of various materials, and is suitable for realistic models and prototyping. Material jetting 3D printing technology includes:

The technology works by jetting microscopic droplets of liquid photopolymer onto a build tray. Each layer is cured with UV light immediately after deposition, ensuring accurate and fine layer resolution. The process supports the use of support materials that can be easily removed, enabling the creation of intricate geometries and overhangs.

PolyJet is widely utilized in industries such as product design, automotive, and healthcare for prototyping and producing detailed, realistic models

MATERIAL EXTRUSION

In the FDM process, a filament of thermoplastic material is heated to its melting point and extruded through a nozzle in precise layers. The nozzle moves along the predetermined path, depositing the melted material layer by layer, gradually building up the final three-dimensional object. The layers quickly solidify upon deposition, creating a durable and structurally sound product.

FDM supports a variety of thermoplastic materials, including PLA, ABS, PETG, and more. This versatility allows users to choose materials based on specific requirements such as strength, flexibility, or heat resistance. Additionally, FDM technology often includes a support material that can be easily removed, enabling the printing of complex geometries and overhangs.

This technology is widely used for rapid prototyping, product development, and even low-volume production. FDM 3D printers come in various sizes, from desktop models suitable for hobbyists to industrial-scale machines for large-scale manufacturing. Its accessibility and ease of use make FDM an ideal choice for a broad range of applications in industries like aerospace, automotive, healthcare, and consumer goods.

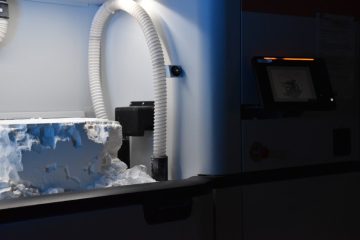

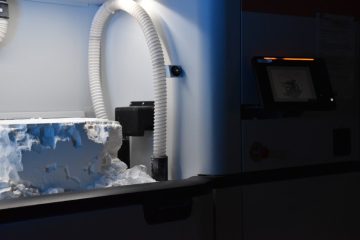

POWDER BED FUSION

Powder Bed Fusion (PBF) uses heat, typically a laser or electron beam, to fuse powder particles layer by layer.

In the SLS process, a thin layer of powdered material is evenly spread across the build platform. A laser then selectively sinters or fuses the powder according to the cross-section of the 3D model, solidifying the material in the desired shape. The process is repeated for each layer until the entire object is formed within the powder bed.

One notable advantage of SLS is its ability to produce complex geometries and intricate designs without the need for support structures, as the unsintered powder acts as a self-supporting material during the printing process. Additionally, the layer-by-layer approach enables the creation of functional, durable parts with high precision.

SLS is widely used in various industries, including aerospace, automotive, and healthcare, for rapid prototyping and the production of end-use parts. The technology’s ability to work with a range of materials and produce objects with strong mechanical properties makes it a popular choice for applications requiring robust and intricately designed components.

SHEET LAMINATION

Sheet Lamination builds a 3D part by stacking thin sheets of material layer by layer. The sheets are bonded or welded through ultrasonic bonding or brazing and then cut to reveal the final 3D printed part.

DIRECT ENERGY DEPOSITION

Direct Energy Deposition is an additive manufacturing process using a multi-axis arm-mounted nozzle to deposit melted material onto a surface. This process, commonly used with metal powder or wire, allows for movement in multiple directions and is not fixed to a specific axis.

Get a better understanding of the use of additive manufacturing compared to traditional manufacturing techniques.

CNC and 3D printing are two widely used manufacturing technologies, but how do they compare? In this article, we explore the differences between them both.

What are the differences between injection molding and 3D printing? Discover which is best for your project.

Choosing the right 3D printing technology involves considering various factors based on your specific needs, project requirements, and available resources. Here are some resources to help you make the best decision for your project:

Let’s compare Selective Laser Sintering and Selective Laser Melting 3D Printing Techniques to get a better understand of their benefits and applications

Are there differences between FDM and FFF 3D printing technologies? Discover all you need to know about these two technologies.

Are you looking for a plastic 3D printing technology? If you are considering MJF and SLS, let’s look more closely at their similarities and differences.

Let’s focus on two innovative 3D printing technologies: SLA vs SLS. Which technology is better to 3D print your project?

Discover all the reasons why you should use Metal 3D printing instead of Metal Casting.

Discover the differences between FDM, SLS, and SLA 3D printing technologies. Find the right technology for your project.

3D printing has found widespread use in various industries, including aerospace, healthcare and automotive. Learn how these technologies are revolutionizing production processes, reducing costs, and enabling rapid prototyping.

Beyond industrial use, 3D printing has become accessible to consumers. From personalized products and home decor to customized fashion and hobbyist creations.

One of the key drivers of 3D printing evolution is the continuous development of materials. From traditional plastics to advanced composites and even bioplastics ors biodegradable options, explore how material science is expanding the possibilities of 3D printing.

Recent advancements have significantly enhanced the speed and precision of 3D printing technologies. This section discusses breakthroughs in printing speed, layer resolution, and the integration of artificial intelligence for optimized printing processes.

The future of 3D printing holds exciting possibilities, with bioprinting emerging as a frontrunner. Explore how 3D printing is poised to revolutionize medicine, from organ transplants to personalized prosthetics.

As environmental concerns grow, sustainable 3D printing practices are gaining traction. Learn about eco-friendly materials, recycling initiatives, and the role of 3D printing in promoting a greener manufacturing landscape.

The list of 3D printing technologies and processes continues to grow as 3D printing is always changing. The 3D printing industry continues to innovate its hardware as well as the materials and processes to create objects or parts. Depending on many factors such as budget, design or function, choosing the appropriate 3D printing process as well as the right material is important. 3D printing can create many different 3D printed objects that were previously only fabricated through mass manufacturing methods.

An online 3D printing service like Sculpteo exists due to the complexity, time and skills required for the printing and Finishing steps. This complexity may hinder people from using this wonderful technology, but at Sculpteo we apply our knowledge to serve anyone willing to try 3D printing, as we want to broaden access to additive manufacturing technology.

FDM or Fused Desposition Modeling is certainly the most popular 3D printing technology, the most known by the general public. This the most used 3D printing technology as it is the most accessible one at the consumer level.

Carbon Fiber Reinforced Nylon merges the strength augmentation from carbon fiber additives with the resilience and durability of nylon. This combination results in a 3D printing material known for its overall strength, making it one of the most robust options available.

Get the latest 3D printing news delivered right to your inbox

Subscribe to our newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook