Master your 3D printed jewelry: the best finishing options

Posted By Kat Plewa on Dec 10, 2019 | 0 comments

Additive Manufacturing can be a great asset to your jewelry business. When it comes to producing jewelry with 3D printing, it’s important for you to choose the right technology, material, but also the finish. What finishes are available for Additive Manufacturing? How can you improve the quality and look of your 3D printed jewelry? Today, we will discuss the advantages of certain finishes and how you can benefit from them. Let’s get started!

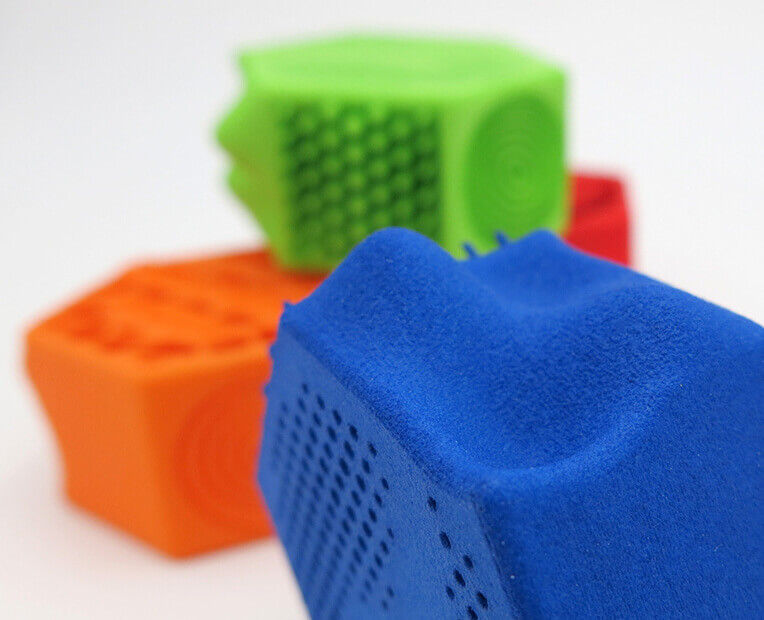

The most popular finishes for 3D printed jewelry are polishing, plating and coloring. There are various coloring methods for you to choose from: dying, painting, color touch, and color resist. There are also several color options available for plating. In the next chapter, we will introduce you to materials that can be polished and the materials that can be colored and plated.

Polish them out

One of the first 3D printing finishes that come to mind is polishing. Mechanical polishing will result in your 3D printed jewelry being smooth, leaving it more pleasant to the touch. This is an essential step as jewelry will have constant contact with the user’s skin. Which materials can be polished?

Nylon PA12

With SLS technology, your jewelry will be 3D printed layer by layer with fine plastic powder Nylon PA12. Originally, it will be white. This material offers a lot of finishes and polishing will smooth the surface of your object.

Nylon PA12 Grey

Parts printed in Nylon PA12 Grey are also manufactured with SLS technology. Thanks to the mechanical polishing process, your 3D models will barely show any layers. 3D printed jewelry with this material will be grey and can provide you with raw-looking, yet smooth products.

Nylon 3200 Glass-Filled

Nylon 3200 Glass-Filled, as the name suggests, has additional glass fibers the powder. This solution makes the material stronger and durable. This material is great for 3D printed jewelry projects thanks to its resistance. Polishing your parts will result in beautiful, white, yet robust and smooth jewelry.

Alumide

Alumide is a plastic one of a kind. It is a plastic powder mixed with aluminum which gives it an elegant, shiny look. It is also used with SLS technology. Polishing adds to the visual effects of Alumide in terms of brighter color and sleek finish. This material can be certainly beneficial for jewelry making, however, it’s not as strong. It will be more suitable for jewelry which doesn’t require elasticity such as earrings or pendants.

MultiJet Fusion PA12

MultiJet Fusion technology was developed by HP and it also uses plastic powder to produce the models layer by layer. However, to fuse the powder locally, it drops a binding agent instead of using a laser. This material produces great quality parts that are somewhat flexible. The polishing finish offers a very nice smooth finish, the difference is certainly noticeable when you touch the object, which is crucial for jewelry such as bracelets.

Steel/ Bronze 420SS/BR

Steel/Bronze 420SS/BR is a great material for decorative applications, made with Binder Jetting technology. As the name suggests, this technology jets a binding agent to produce your objects. Originally, the surface of this material is porous, so polishing it makes a great difference when it comes to the smoothness of your objects. With this material, you can produce beautiful 3D printed jewelry.

Stainless Steel 316

This 3D printing material is also used with the Binder Jetting method. However, it has different properties from the previous material. It’s great for small objects. In the raw state, Stainless Steel 316 has silver color and granular surface. Thanks to polishing, your object will be more smooth and shiny.

Casting materials

Silver, Brass, and Bronze are 3D printing materials used for Wax Casting. They are mainly applied for jewelry making as they give designers a possibility to explore 3D printing advantages combined with the beauty of precious metals. They all are available with a polished finish, giving them, even more, shine and stunning surface finish. We will come back to those materials with the plating options.

What are the solutions for finishing your 3D model in color?

If you aim to 3D print with just one color, you should also consider finishing options such as dying or plating. You don’t have to sacrifice the quality of color prints. The variety of materials is also larger with this solution. You can choose from plastics, resin, and metal. Let’s take a closer look at the options.

MultiJet Fusion PA12

Parts produced with MultiJet Fusion will be grey, but they can have black color achieved through one of the two dying options. The color will be resistant and will last long. What are the techniques to get your 3D printed parts colored?

- Dyed with color resist: color applied in a water bath where dye penetrates the plastic through a chemical reaction under pressure and heat

Available colors: black

- Dyed with color touch: the process is the same as color resist, additionally your parts will be polished for a smoother surface finish

Available colors: black

Nylon PA12

Nylon PA12 offers the most coloring options. There are 4 techniques to get your parts more colorful: dying, painting, color resist, and color touch. How are they different and which one is better for your 3D printed jewelry?

- Dyed: color applied in a heated dye bath

Available colors: blue, yellow, red, green, orange, black

- Painted: color applied through the surface coating

Available colors: blue, yellow, red, green, orange, black, stone grey, grey, gold, silver, violet, brown, pink

- Dyed with color resist: parts are dyed in a water bath where the color is applied through a chemical reaction. This dying option provides you will more durable effect

Available colors: blue, red, black

- Dyed with color touch: the dying process works just like color resist, additionally the objects are polished

Available colors: blue, red, black

Alumide

Alumide can certainly be an interesting option to produce your 3D printed jewelry. It gives you new possibilities when it comes to color 3D printing technology. Thanks to the addition of alumide, you will be able to achieve a surprising effect. The 3D printer will produce gray models that later are bathed in pigment and cleaned. Available colors: blue, red, green, and black.

VeroWhite

3D printed with PolyJet technology, VeroWhite resin provides you with various dying options for high-quality 3D printed jewelry. Thanks to a thin material layer, your 3D models will have a smooth surface finish and can achieve a great level of detail.

- Dyed: color applied in a heated dye bath

Available colors: black, light yellow

- Painted: color applied through the surface coating

Available colors: neon yellow, neon orange, neon pink, intense red, orange, marrow glace, pearl gray, odyssey blue, valley green

Steel/Bronze 420SS/BR

If you’re interested in getting your jewelry 3D printed with metal, don’t think you’re limited just to one color. Thanks to plating options, you can enjoy color 3D printing for metals too, for example with Steel/Bronze 420SS/BR. Your plating options are: gold, silver, and black.

Brass

Casting 3D printing technology allows you to achieve different colors with Brass material. Your 3D models will be 3D printed with wax to produce a mold, and then substituted with brass metal. Thanks to combining additive manufacturing and traditional manufacturing technologies you can achieve highly complex and detailed 3D printed jewelry. You can choose between pink gold, gold, black rhodium, and white rhodium platings.

Which finish do you choose?

As you can see your 3D printed jewelry can be improved either by polishing, coloring or even combining them. The 3D printing process doesn’t have to finish when your jewelry is manufactured, there are additional steps for the best quality products. Benefit from the design freedom 3D technologies offer without sacrificing the visual aspect! Have you made up your mind? Hopefully, this article made the finishing options more clear for you, but feel free to ask for advice from our 3D printing experts.

Have you decided on a finish already? Start 3D printing today! Simply upload your 3D file to our online 3D printing service and improve your production without leaving your house.

Stay up to date with the latest 3D printing, sign up for our Newsletter and follow us on Facebook!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook