Indirect color 3D printing applies the color from an external source during the printing process. This technology is much more precise and allows for a more realistic appearance of the 3D prints, but in most cases, the process requires professional knowledge. It is important for you to remember that indirect color 3D printing uses CMYK color mode and you need to take that into consideration when preparing your model.

ColorJet technology

With ColorJet technology you have a choice of 36 000 colors! Your 3D files need to carry the color and texture information before it’s sent for multicolor 3D printing. During the 3D printing process, fine, sandstone-like powder is used. A layer of the material is spread, then the printing heads apply color that adheres to the layer. The next layer is spread and the process repeats.

The results are pretty impressive! Thanks to the wide range of colors, you can achieve so much more than with direct color 3D printing. This solution is especially interesting for designers to present proof of concepts to their clients, architects to produce visual models, and for game character production.

PolyJet technology

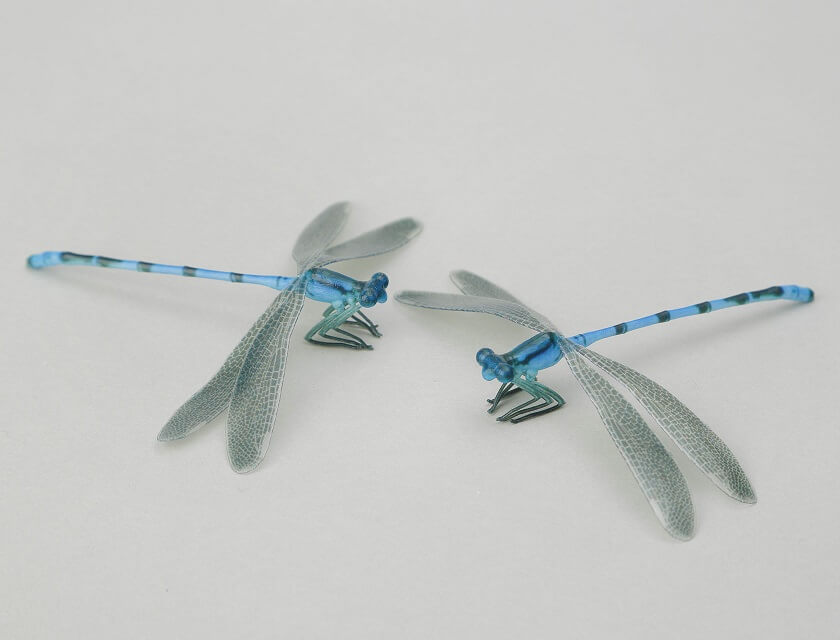

PolyJet technology works with liquid resin and prints at impressive 16 microns which assures very fine detail and good surface finish of your 3D models. In between the layers, color is applied and cured with UV light. This technology lets you adjust even the level of transparency of the colors.

HP’s 3D printing solutions are revolutionary in the world of Additive Manufacturing. HP’s engineers started by studying light and how to use it in order to produce evenly colored 3D printing, at the quality of regular 2D printers.

Their color 3D printer uses an innovative binding agent to fuse the plastic powder locally. The color is applied at a level of 3D printing DNA called the ‘’voxel’’, a three-dimensional pixel. Thanks to that you can achieve color 3D printing even with very complex objects.

Mimaki

https://mimaki.com/special/3d_print/gallery.html

This company is a true champion of color 3D printing. When we talk about full-color 3D printing, they are a real winner, bringing to the market machines capable of using over 10 million colors! Their technology is based on UV light which was originally developed for regular, paper printers.

A layer of powder material is spread, and then pigmented resin is dropped with the inkjet head of the 3D printer. The next step is UV curing the resin into a solid-state. The process repeats and your 3D prints are produced in great, vibrant colors.

Desktop 3D printers for indirect color 3D printing

Some companies take yet another take on indirect color 3D printing in order for it to be reachable from your desk. There are a few ways to deal with that. One of them is actually using paper. CMYK inks are dropped on the paper and then the layer of paper is die-cut and fused with the next one. The downside is a risk of the ink spreading or bleeding.

Another solution is the ink absorbent filament. FDM 3D printer lays a layer of the filament and before the next layer is applied, it drops CMYK ink. This technology is impressive, although the results can be quite soft and translucent. Check out Da Vinci Color to discover more.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook