3D printing with plants: How is it possible?

Posted By Lucie Gaget on Oct 5, 2018 | 0 comments

3D printing is constantly evolving, new 3D printers, new 3D printing materials are unveiled regularly. Today, we chose to talk about a brand new 3D printing material that might surprise you: a vegetal 3D printing material. Discoveries made in the additive manufacturing industry are always more and more surprising but always allowing new impressive applications. It is now possible to 3D print with plants and it could soon become an alternative to petroleum-based materials.

What is this mysterious vegetal material? What could it be used for? All you need to know about this astonishing discovery is in this blog post.

3D printing with plants: A new challenge for researchers

What is this new vegetal 3D printing technique?

This new 3D printing discovery comes from Tennessee, in the United States and has been made by the Oak Ridge National Laboratory (ORNL). This laboratory is particularly interested in 3D printing, for example, they worked on an XL 3D printer in order to create a 3D printed excavator in 5 hours only.

But the nature of the new discovery mode this team of researchers is quite different. Indeed, they made the astonishing bet to develop a new printable material, made with plants. This special material is composed of rubber, carbon fiber, ABS (Acrylonitrile Butadiene Styrene) and lignin, a complex organic polymer. Lignins are present in the formation of cell walls, especially in wood and bark. It is offering a great rigidity and doesn’t rot that easily.

Why are all these materials needed to create this lignin-based material? Rubber and ABS are here to bring tensile strength, while carbon fiber is giving more strength, and is also allowing to make the whole composite easier to print. The final material is made of 40% of lignin.

3D printing, the perfect solution to manufacture lignin-based composite

3D printing is always going further. Wanting to work with a new material is amazing, but manufacturing it, shaping it can be a real challenge. Researchers from the ORNL perfectly took this challenge and found solutions.

The ORNL team want to composite to be used to manufacture at an industrial scale, but it can be quite complex as this material cannot fit with all manufacturing technologies. Indeed, compressing molding and casting are the most used techniques when it comes to organic polymers.

But for this first experiment, researchers had to find another way to work this new material, as it is quite hard to process.

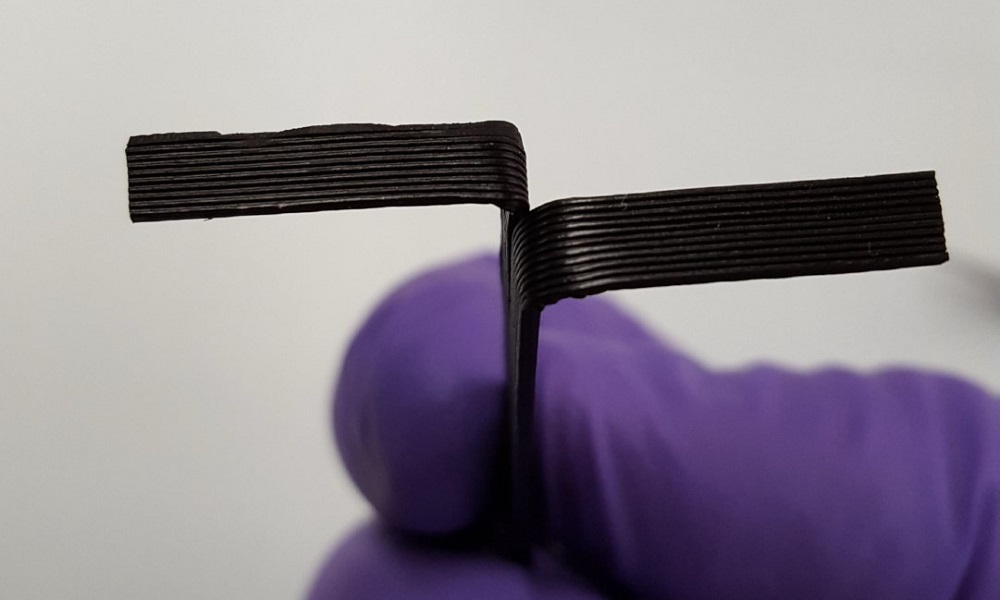

They were looking for the best manufacturing process for this new composite. What about 3D printing? The team decided to 3D print the plant-based material, using the FDM (Fused Deposition Modeling) to create their parts. A real success, as you can see in the video below:

By mixing the lignin with ABS, rubber and carbon fiber, it has been possible to create a 3D printable filament. It is for the moment this only way to print a plant-based material, but here at Sculpteo, we know that new vegetal 3D printing methods will emerge in the upcoming years!

Plant-based materials: An alternative to biofuel?

You are certainly wondering how this vegetal 3D printing material could be useful. Actually, this 3D printable lignin could be a great alternative to petroleum-based materials. It has the same mechanical properties and could even be better than traditional biofuels.

Indeed, this lignin composite is a byproduct of producing biofuels. This organic polymer enables a better adhesion between the ABS layers, making the product more resistant.

The goal of these researchers is to use this process and this new material at an industrial scale, to replace traditional plastic. Additive manufacturing is making it possible, and the use of vegetal 3D printing could spread in the upcoming years!

Amit Naskar, a researcher from the ORNL explained that the development of this material took 5 years, but they are still working on this lignin-based material to make it even more resistant. This first experiment is really promising for the 3D printing industry.

The will to create new eco-friendly solutions is present in all the different industries. Scientist and researchers all have in mind this hope of avoiding pollution and reducing wastes. Additive manufacturing is maybe the perfect technique to develop green manufacturing, eco-friendly materials, and so on!

The development of new 3D printing materials like this one is offering new possibilities. Researchers are allowing to bring to reality better and more efficient materials, which will help to create projects with new incredible properties. Vegetal 3D printing is only at its early stages, but regarding its potential, it will surely evolve quite quickly.

What do you think about the use of plants to 3D print? Would you be ready to manufacture your product thanks to vegetal 3D printing? Share your views with us in the comments.

If you want to receive all the 3D printing news, be sure to subscribe to our weekly newsletter!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook