Direct digital manufacturing

Online 3D Printing Service

Online laser cutting service

Capabilities

FAQ

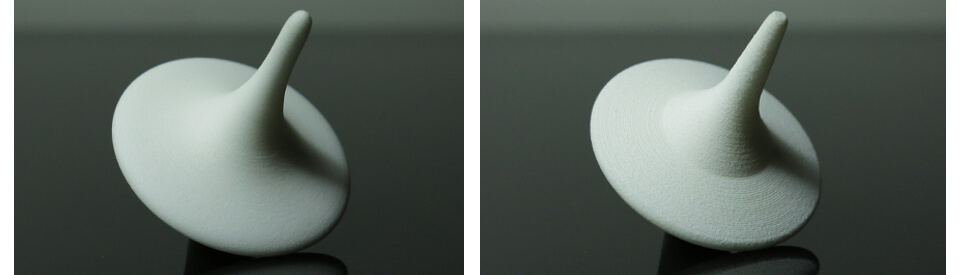

POLYMER POWDERS

PHOTOPOLYMER RESINS

POLYMER FILAMENTS

Get free shipping and 10% off your first order!

✖

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook