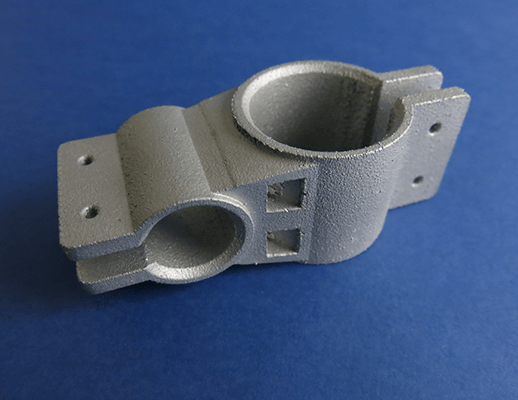

- To work on complex designs

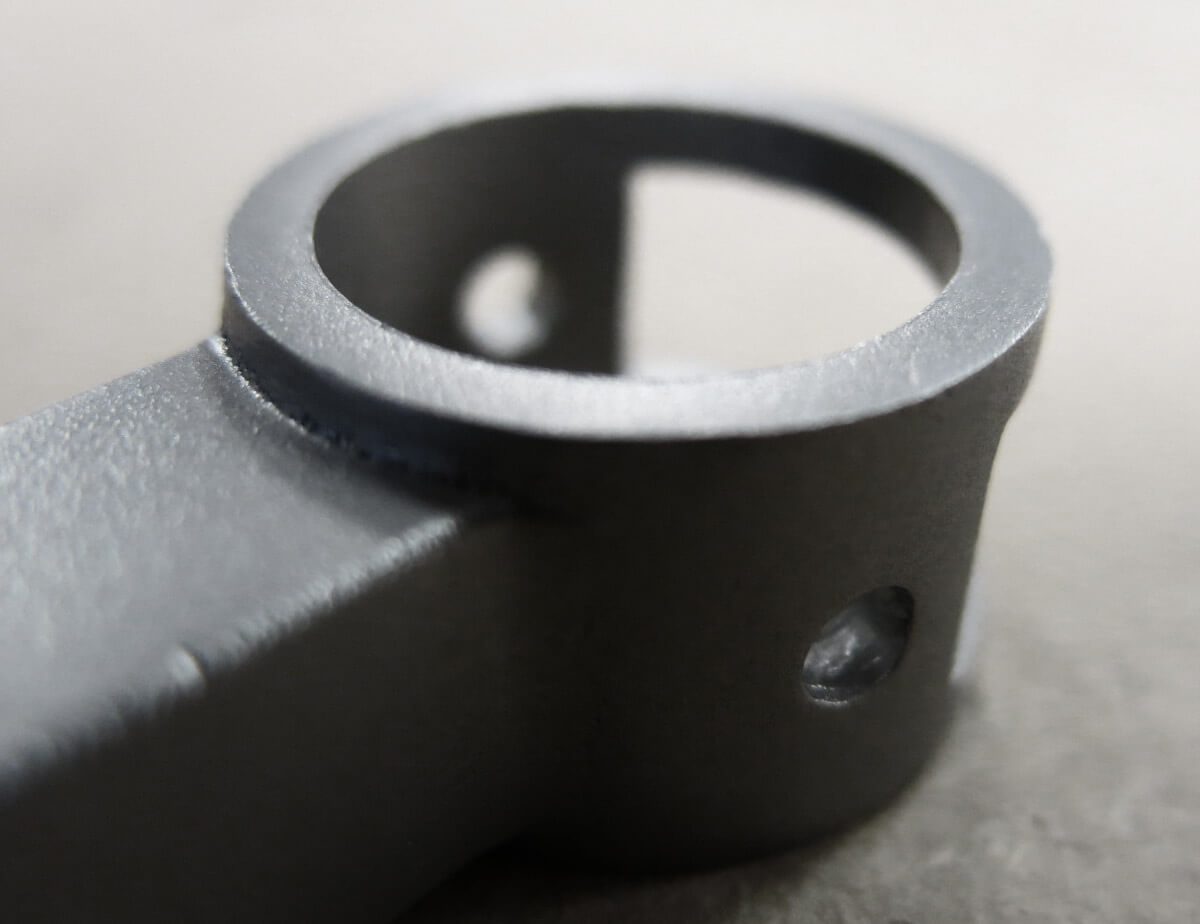

3D printing is a great way to elaborate complex designs. By using a 3D modeling software, you will be able to design any kind of projects. When designing your project for metal printing, you will have to pay attention to the design guidelines of the material you choose, in order to create a printable and viable part.

Additive manufacturing is the best solution if you need to manufacture custom-made objects. Indeed, this method will be quite cost-efficient for these projects, as you just have to modify your 3D design and print it using, for example, a 3D printing service such as Sculpteo.

Using a 3D modeling software offers many advantages. You have a total control on the object that will be manufactured. It is the perfect method to optimize directly the design of your project, by modifying the shape or adding structures such as lattices. 3D printing allows to optimize your part by reducing weight, or work on the resistance of the part.

- Short runs at a lower cost

Additive manufacturing is a really convenient and cost effective technique to manufacture short runs. Indeed, it can totally be a cost efficient method for your project, depending on the technology, on the 3D printing material Have you ever thought about applying these 3D printing benefits to your metal projects? You should certainly think about it.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook