Companies across sectors have already perceived the benefits of mass-customization and 3D printing. Here are some examples of very innovative projects that this technology made possible, to boost your creativity:

High-end furniture customization and 3D Printing: Poltrona Frau

Credits: Poltrona Frau

The exclusive Italian furniture company, Poltrona Frau, is one example of a company that makes good use of 3D printing for mass customization and allows customers to customize the furniture pieces themselves. Poltrona Frau offers customers a 3D tool on the website for them to visualize their furniture and then to be able to customize it. Because high-end furniture companies like Poltrona Frau already implemented manual customization even before the use of 3D printing, 3D printing allowed then for them to have a manufacturing technique that is faster and reduces labour (costs) in general.

3D Printing mass-customization in the Car industry: BMW’s MINI Yours

Credits: MINI Yours Customized

Mass customisation can even be implemented in the automotive industry. For BMW’s MINI series, the MINI Yours Customized service was brought into existence for BMW MINI users. This service is a fine-tuned and fully implemented mass customization service. A new online shop was set up where clients can indicate the customized changes they would like to have implemented for specific parts of the BMW MINI – such as the door handle or parts of the side plate. These customized parts are designed to the client’s creative style and made from the same high-quality materials that the actual car itself is made from.

Mass-customized scale models: 3D printed Skoda Fabia models

Staying within the automotive industry, Skoda’s mass customized 3D project is one to mention as well as it was part of their marketing strategy. In order to increase product awareness and traffic of their (partnered) car dealerships, Skoda invites clients to their website and lets them create a customized Skoda Fabia with a 3D modelling window implemented in their UI. The website and UI for this project were devised by Shivacom and our team at Sculpteo were in charge of 3D printing the customized Skoda models. This customized Fabia will then be produced but in pocket format. The possible client can then pick up the customized Fabia at one of the dealerships where he/she then experiences a real-life-test drive with a Fabia model: A perfect example of experience economy where customers try something out before purchasing and thus increasing the likelihood of an actual purchase.

Mass customization in the Electronics industry: 3D printed NORMAL earphones

Credits: NORMAL

Earphone producer Normal makes customized 3D printed earphones. The customization is done in a specific way. By downloading their app, one can take a picture of one’s ear, then upload it to the app which then allows the user to receive custom earbuds, fitted to their ear size and comfort preference. The picture of the ear itself is merely 2D but Normal is able to produce a custom-fit pair of earphones within 48 hours.

Mass customization in the medical sector

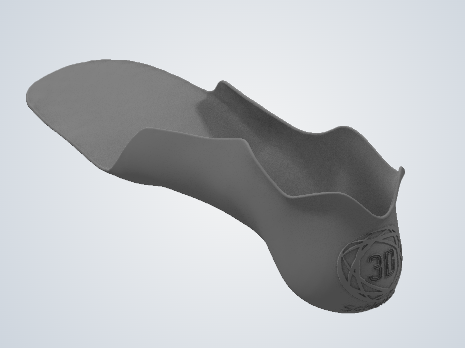

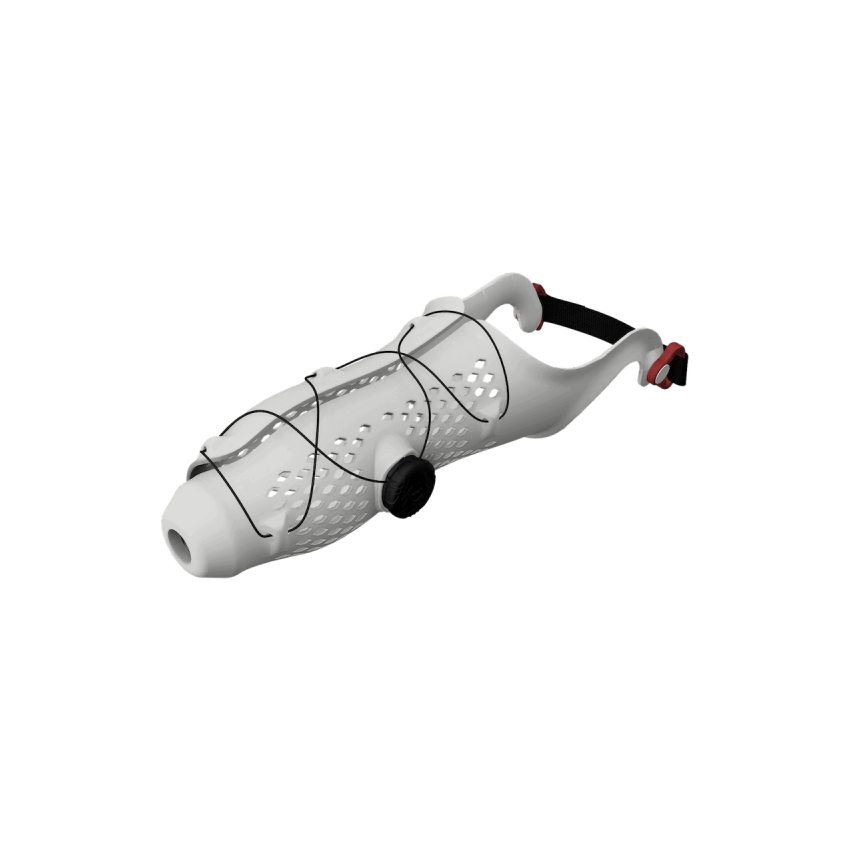

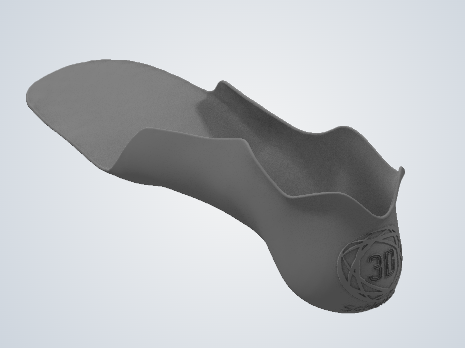

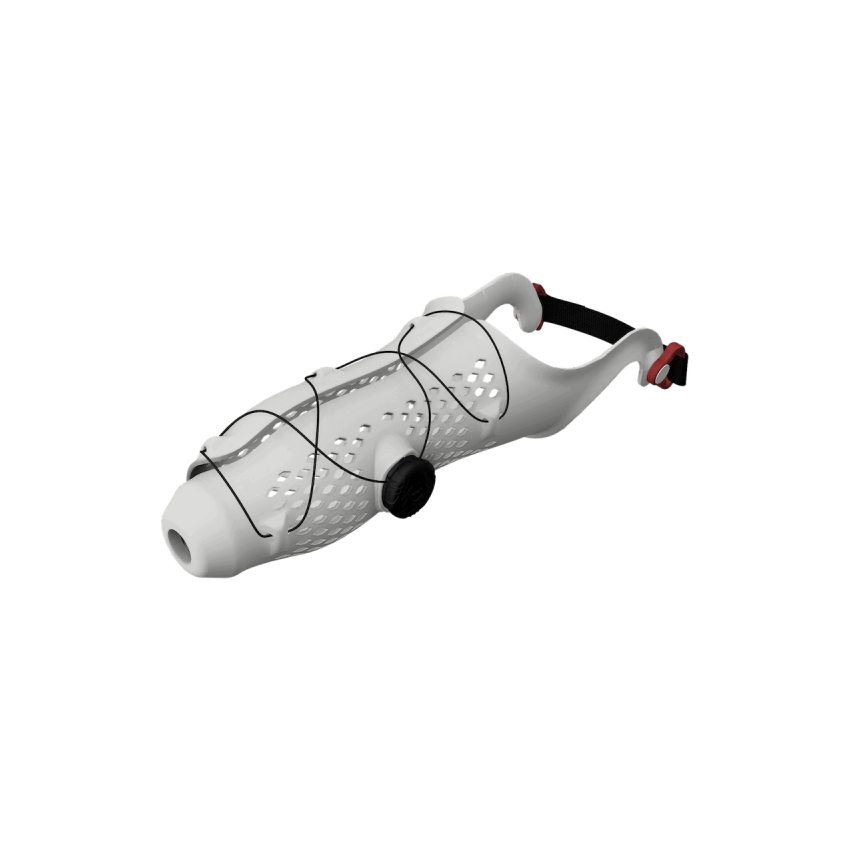

Mass customization is becoming a great asset for the medical sector, giving new perspectives and opportunities to healthcare workers. For example, Additive manufacturing became a real alternative for the creation of orthosis and prosthetics. Thanks to mass customization and the freedom of design allowed by 3D printing, it is possible to create medical aids perfectly adapted to the patient’s morphology and needs.

At Sculpteo, we are working with several companies creating orthotics and prosthetics to help patients live a better life.

- Schlather: Creating medical aids with additive manufacturing using PP material. The company developed a Dynamic Foot Orthosis (DFO) to correct various deformities such as clubfoot or extremely high arches.

- MacU4: Macu4 turns to the innovative potential of AM to create arm prostheses that are affordable, lightweight, and versatile.

- Daniel Robert Orthopedic: They explored 3D printing to offer a unique and custom device that allows for comfort, and breathability and is lightweight, while still maintaining flexibility in manufacturing and design.

Obviously, these examples of 3D printing mass-customized products are just a few. With professional finishing options and more than 20 Additive Manufacturing materials, Sculpteo enables you to customize products in many ways. Upload your 3D file on our online 3D printing platform or get in touch with our sales team and discover how your products can be mass-customized with Additive Manufacturing.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook