3D printed tools: The most useful projects

Posted By Lucie Gaget on May 30, 2018 | 0 comments

Additive manufacturing can be used for various applications inside a company, from prototyping to production. It is possible to create a lot of different 3D printed objects, and among them: 3D printed tools. Indeed, companies can use 3D printing to manufacture useful tools.

Manufacturing these devices with 3D printers allows to get custom made tools, to print tools in a remote area and to work on the design of the tool. We are going to see how 3D printing can help all kind of industries to manufacture tools and we will show you a selection of the most useful tools created with 3D printing. Get inspired by these 3D printed tools and boost your competitiveness!

Why is it interesting to 3D print tools?

Improving your efficiency

3D printing has a major advantage: it will help you maximize your production efficiency. You certainly know it if you are reading our blog, but implementing additive manufacturing in your business will influence your productivity.

You will get a better product development process, as you will work on your computer, with a 3D software to create iterations of your products. And for your end-use products, you will access a wide range of 3D printing materials and efficient technologies. You will find the perfect material, with the perfect properties, that will match your expectations and fit your final project. You can totally elaborate prototypes for your tools, and then even use 3D printing to produce them.

Reducing your costs

Cost reduction is one of the most interesting assets of 3D printed tools. The tooling budget of companies is really important, and if you think about 3D printing to manufacture your products, you may not think about this additive manufacturing method to create your tools!

For example, Volkswagen Autoeuropa, the car manufacturer, is using 3D printing to manufacture some of its tools. The company estimates that thanks to 3D printing they saved 250,000€ in 2017. Reducing your tooling investment thanks to 3D printing could be the perfect solution.

If you use a 3D printing service such as Sculpteo, you will have the choice between numerous materials adapted to your needs and budget, and various options to save money, such as our hollowing tool.

Tools more adapted to your applications

Everything is 3D printable: tools, jigs, and fixtures. You have the choice, you can create your own tools from scratch or you can take existing tools and adapt them to your needs. Thanks to 3D software and the 3D printing technology, everything is possible. It could become a way to modernize your manufacturing process by improving your tools.

You can rethink totally your tools and make them lighter, you can modify their design to make them more convenient for your use. Regarding the design, you are completely free. You can create complex shapes, that would be impossible to make with traditional manufacturing methods. You can create the same object with little modifications each time. This custom made aspect is a real advantage for some industries, such as the medical industry.

What are the most useful 3D printed tools ever created?

3D printed tools for the automotive industry

3D printing is a great asset for car manufacturers, allowing to print tools but also car components. Here is, for example, a wheel protection jig used by Volkswagen Autoeuropa, that normally costs 800€ but can now be printed for only 21€:

https://3dprint.com/178994/volkswagen-autoeuropa-ultimaker/

We just told you about Volkswagen reducing their tooling budget, but it is not the only car manufacturer using 3D printing. BMW and Opel are also using the 3D printing technology to create tools for their assembly line. They make the most of this technology and this way, reduce time and costs, which make a big difference in the end!

These are three of the biggest car manufacturers in the world, it also shows that the 3D printing technology is a reliable method, that can be used by all kinds of companies.

3D printed tools for the medical industry

There are various applications of the 3D printing technology in the medical industry, even when it comes to tools. We will see that this technology allows to create devices adapted to the needs of surgeons, to create innovative designs but also to give an access to medical tools in remote areas.

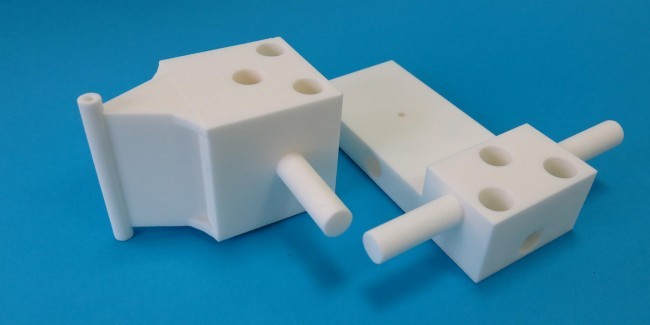

3D printing surgical devices

3D printing is a huge asset for the medical industry, to create 3D printed implants or prosthesis perfectly fitting the patient’s morphology. But additive manufacturing can also be used to create specific tools, such as surgical tools. Indeed, additive manufacturing appears to be the perfect method to manufacture medical devices as surgeons often need specific devices to find the best solution for their patients and save lives.

You may know this, but 3D printing allows mass customization, you can make various iterations of the same 3D model, with little modifications each time to adapt it. You can also just elaborate your 3D tools project, we had the example on our blog with Marc Soubeyrand. This surgeon is using 3D printing to create his own tools with plastic materials for orthopedic surgeries!

3D printed needles

Two researchers from the Temple University developed a 3D printed medical device that is really accurate and is specially made to reduce skin damages. They created a 3D printed needle. These 3D printed polymer needles have a design inspired by honeybee’s stingers.

Indeed, these needles have notches that are actually reducing the force of the needle’s insertion and extraction. It is painless and will leave a smaller mark on the skin. Thanks to 3D printing they are able to develop a needle with a new design and with very accurate details.

3D printed tools, saving lives in remote areas

The goal of the project started by the organization ReFab Dar is to manufacture 3D printed tools on-site with recycled plastic in Tanzania. First, it could allow to reduce plastic waste, and it would be the perfect solution to create low-cost tools and help to save lives, in an area where finding medical tools can be difficult as they have to import them. This is the perfect example of how useful 3D printing can be when it comes to medical tools!

3D printing tools directly in space

We just saw that 3D printing is quite convenient to manufacture tools and other devices for remote areas, as it is allowing to create some devices on-site, instead of transporting them in inaccessible places. What is the most inaccessible area where people could need tools? Space! Indeed, astronauts, during their missions, are always in need of some new tools.

https://www.think3d.in/introducing-amf-a-printing-device-that-prints-its-first-space-tool/

As you can imagine, sending some tools there is really expensive. That is one reason why they are implementing 3D printing and using 3D printers during their mission: it is the perfect method to manufacture tools directly in space, when they need it. Moreover, it is also a way for them to manufacture custom-made tools, adapted to their missions.

Made in Space, a company specialized in engineering and manufacturing in space, working with the NASA, made some experiments. For instance, they 3D printed this wrench:

https://www.nasa.gov/mission_pages/station/research/news/3Dratchet_wrench/

These tools will be really useful for astronauts, allowing them to get the right tools, exactly when they need it.

3D printing for farm tools

Do you know that additive manufacturing could be useful for the agriculture field? The Dr Joshua Pearce from the lab of Michigan Tech decided to create farm equipment, essentially for emerging countries. From hand tools to food processing and hydroponics, he created open source tools. This project could mostly help small-scale farmers.

There is still a lot of work to be done on this project, but it could allow to manufacture some adapted tools for people working in agriculture at a lower cost. They need adapted devices and they don’t have a big budget, that is why additive manufacturing can be the answer!

The future of 3D printed tools

It could become more and more common to 3D print for tooling. With the quick evolution of metal 3D printing, it could become really easy and convenient to manufacture metal tools in the future. However, for the moment, if you want to produce tools at a lower cost, a lot of resistant 3D printing materials can be used to create 3D printed tools and help you reduce the costs.

As you can see 3D printing tools has many benefits. In the upcoming years it could totally become a common 3D printing applications for various sectors! 3D printers still have a lot to offer to all of these industries.

Do you want to try 3D printing for your company? Do you need to 3D print your tools in order to improve your manufacturing process? You can upload your 3D models right now on our online 3D printing service.

Subscribe to our weekly newsletter to get all the news on 3D printing applications around the world.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook