The ultimate guide to the best industrial 3D printers on the market

Posted By Kat Plewa on Oct 17, 2018 | 0 comments

Sometimes 3D printing is mistaken for being just a hobby, but it actually has a huge impact on different industries and is being used more and more. With Additive Manufacturing we can already 3D print organs, bones, but also mechanical parts for cars or construction parts for airplanes. And let’s not forget about 3D printing an entire house! This industrial revolution wouldn’t be possible without the best industrial 3D printers.

We will give you an overview of the most innovative industrial 3D printers on the market and why you should use them for your production process. Also, we will talk about a situation where you can’t or simply don’t want to invest in industrial 3D printers, but you still see the potential and benefits of Additive Manufacturing. In that situation, the perfect answer for you is an online 3D printing service such as Sculpteo. Let’s discover all your options.

What are the benefits of industrial 3D printers?

First of all, industrial 3D printers are very powerful in various aspects. They can produce your parts with exceptional precision. Some of them are extremely accurate with the capability to 3D print the models at 28 µm layer thickness. In comparison, the thickness of a single hair is between 17 to 180 µm, which places 28 µm at a pretty impressive resolution of Additive Manufacturing uses.

This aspect of industrial 3D printers also allows for the production of highly complex objects. With Additive Manufacturing you can reach an absolutely new level of design freedom. Thanks to 3D printing you can now design new solutions for your production needs, and with a very wide range of 3D printing materials and techniques, you will surely find the perfect one for your manufacturing requirements. Now, your parts can be highly customized, which was unachievable with traditional production methods.

One of our client’s fully functional Carbonmide part.

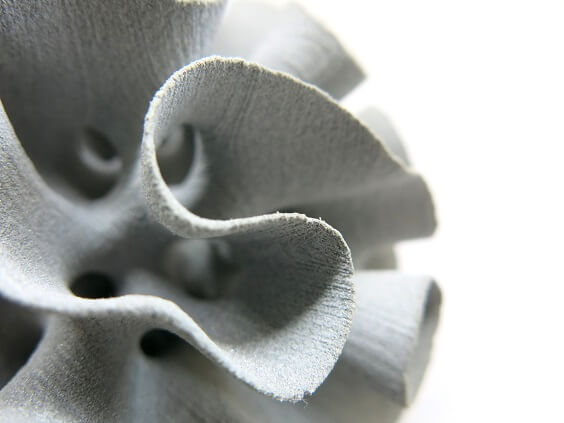

An example of highly complex and detailed Alumide for SLS 3D printing.

Industrial 3D printers are also more economical as they allow for the production of multiple objects. They can be set to manufacture whole batches of products, with the best optimization for low material waste. Not only that but in most cases 3D printed objects are ready to use coming straight out of the industrial 3D printers. Those factors mean lower production costs.

Switching from traditional manufacturing methods to using industrial 3D printers also means much faster production process. 3D printers are quicker, sometimes reducing the manufacturing process from weeks to just days. They don’t involve molding or casting, eliminating a lot of time-consuming processes. Very often, the 3D printed parts are also fully functional and ready for you as soon as the 3D printing process is finished. That means no wasting time on assembling your parts.

Let’s have a look the best industrial 3D printers on the market!

The best SLS printers

SLS is a 3D printing technology based on using plastic powder. The objects are created with a laser beam at a high temperature providing you with strong, robust and fully functional objects. With this Additive Manufacturing method, it’s the design that defines the production, not the other way around. SLS is perfect for low-volume production and prototyping.

EOS P396

One the most powerful industrial 3D printers producers is EOS. The company is one of the pioneers for manufacturing plastic industrial 3D printers. Their EOS P396 has been named the best SLS printer 2017. EOS prides the printer for using 38% less energy at the same time being up to 32% faster. The industrial 3D printer also is known for a better build process, which reduces the component costs. We use this machine on daily basis and would highly recommend it.

| Price | 450 000$ |

| Material | 11 materials: PA 2200, PA 3200 GF, PA 2201, Alumide, PrimePart PLUS (PA 2221), PA 2202 black, CarbonMide, PrimeCast 101, PrimePart ST (PEBA 2301), PrimePart FR (PA 2241 FR), PA 1101 |

| Build size | 13.4 x 13.4 x 23.6 in / 340 x 340 x 600 mm |

| Build rate | Up to 48 mm/h / 1.9in/h |

| Layer thickness | 0.06 mm/ 0.00236 in, 0.10 mm/ 0.00394 in, 0.12 mm/ 0.00472 in, 0.15 mm/ 0.00591 in, 0.18 mm/ 0.00709 in |

| Printer’s dimensions | 72.4 x 46.3 x 82.7 in / 1840 mm x 1175 mm x 2100 mm |

EOS Formiga P110

The latest version of this machine is claimed to be 20% faster thanks to new software and hardware features. This industrial 3D printer is faster and cheaper but at the cost of your print size. We use an older version of this printer, Formiga 100, and it’s serving its purposes properly.

| Price | 100 000 – 250 000$ |

| Material | 9 Polymer materials |

| Build size | 7.9 x 9.8 13in / 200 x 250 x 330mm |

| Build rate | Up to 1.2 l/h / 40.6 oz/h |

| Layer thickness | 0.06- 0.10 – 0.12mm (0.0024- 0.0039 -0.0047) in depending on material |

| Printer’s dimensions | 1320 x 1067 x 2204 mm / 126 x 137.8 x 118.1 in |

EOS P 770

This industrial 3D printer stands out for its build size. It also gives a great choice of 10 polymer materials and 5 thicknesses, which might be crucial for your production. At Sculpteo we use a 760 version and it performs very well with large prints.

| Price | 800 000$ |

| Material | 10 Polymer materials |

| Build size | 700 mm x 380 mm x 580 mm / 27.6 x 15 x 22.9 in |

| Build rate | up to 32 mm/h* (1.3 in/h); up to 10.5 l/h*typical build rate for PA 2200 for 120 μm (0.00472 in) layer thickness |

| Layer thickness | 0.06 mm (0.00236 in), 0.10 mm (0.00394 in), 0.12 mm (0.00472 in), 0.15 mm (0.00591 in), 0.18 mm (0.00709 in) |

| Printer’s dimensions | 2250 mm x 1550 mm x 2100 mm (88.6 x 61 x 82.7 in) |

EOS P 500

This industrial 3D printer is the ultimate solution for the production of high-quality parts at the lowest cost-per-part, as the manufacturer says. It is suitable for aerospace and automobile industries as it stands out for its thermal and optical monitoring as well as its sensor technology. It also allows for processing of advanced polymer materials thanks to high temperature operating (up to 300°C).

| Price | Starts at 250 000$ |

| Material | White polyamide powder or PEKK |

| Build size | 500 x 330 x 400 mm (19.7 x 13 x 15.7 in) |

| Build rate | up to 40 mm/h (1.6 in/h); up to 6.6l/h |

| Layer thickness | 0.06 mm (0.00236 in), 0.10 mm (0.00394 in), 0.12 mm (0.00472 in), 0.15 mm (0.00591 in), 0.18 mm (0.00709 in) |

| Printer’s dimensions | 3,400 x 2,100 x 2,100 mm (133.9 x 82.7 x 82.7 in) |

MultiJet Fusion by HP

HP is mainly known for regular printers we have in the offices or at home. But this global tech giant saw the potential of Additive Manufacturing and couldn’t miss the opportunity to enter the market. HP flipped the 3D printing industry upside down with their innovative MultiJet Fusion technology.

The revolutionary manufacturing technique was invented by HP in a multi-agent printing process. With their development, the 3D pints are very detailed and at a great accuracy. The MultiJet Fusion 3D printing process is explained in the video below.

Jet Fusion 300/ 500 series

The newest development of HP is the industrial 3D printers series 300/ 500. What is so revolutionary about those industrial 3D printers? It is the capability to 3D print in full-color your engineering- grade parts. Also, their price catches attention, making Additive Manufacturing more accessible to small and medium businesses. The series includes:

- HP Jet Fusion 340 (Black and White)/ 380 (Color): which has a smaller build size

- HP Jet Fusion 540 (Black and White)/ 580 (Color): meets heavier production needs

| Price | 20 000$- 120 000$ |

| Material | HP 3D High Reusability CB PA 12 |

| Build size | 340/ 380: 7.5 x 10 x 9.8 inches (190 mm x 254 mm x 248 mm)540/580: 7.5 x 13.1 x 9.8 inches (190 mm x 332 mm x 248 mm) |

| Build rate | up to 52 parts in 15 hrs |

| Layer thickness | 0.08 mm (0.003 in) |

| Printer’s dimensions | 61.6 x 37.6 x 59.3 inches (1565mm x 955mm x 1,505mm) |

Jet Fusion 3D 4200 Printing Solution

This series of industrial 3D printers is aimed for large volume. If your production needs are to manufacture 130- 599 parts per week, HP’s innovative take on Additive Manufacturing technology is the right solution for you. We use this industrial 3D printer for our business and we can surely recommend it for precise and robust parts as well as functional prototypes.

| Price | Starts at 200 000$ |

| Material | HP 3D High Reusability CB PA 12, PA 11 and PA 12 Glass Beads |

| Build size | 380 x 284 x 380 mm (15 x 11.2 x 15 in) |

| Build rate | 4115 cm³/hr (251 in³/hr)15 |

| Layer thickness | 0.08 mm (0.003 in) |

| Printer’s dimensions | 2210 x 1200 x 1448 mm (87 x 47 x 57 in) |

Jet Fusion 3D 4210 Printing Solution

The second generation of industrial 3D printers from HP is just as efficient but aimed for high volume production, 600- 1000 parts per well. With this 3D printer, you can achieve the best optimization between manufacturing costs and quality at a larger scale.

| Price | Starts at 200 000$ |

| Material | HP 3D High Reusability CB PA 12, PA 11 and PA 12 Glass Beads |

| Build size | 380 x 284 x 380 mm (15 x 11.2 x 15 in) |

| Build rate | 4115 cm³/hr (251 in³/hr) |

| Layer thickness | 0.08 mm (0.003 in) |

| Printer’s dimensions | 2210 x 1200 x 1448 mm (87 x 47 x 57 in) |

Resin technology

If you are looking for the ultimate smoothness of your parts and the best looks of your 3D models, the resin materials are the way to go. They will provide you with very sleek parts. Resin industrial 3D printers are recommended for small parts and rapid prototyping.

Stratasys Object30 Pro

Stratasys’ industrial 3D printers use PolyJet technology is based on using resin materials and for this industrial 3D printer they can be clear, high-temperature and simulated polypropylene, which will provide you with highly complex parts. Object30 Pro also offers very high accuracy and beautiful surface look. At Sculpteo we also provide with the ability to use Object30 Pro with our online 3D printing service, and we suggest this technology is highly beneficial to produce accurate parts for prototyping and low-volume production.

| Price | Starts at 20 000$ |

| Material | VeroClear Transparent, RGD525 High Temperature, VeroWhitePlus Opaque, VeroBlue Opaque, VeroBlack Opaque, VeroGray Opaque, DurusWhite Polypropylene-like |

| Build size | 54 x 251 x 203 mm (10 x 9.88 x 7.99 in) |

| Build rate | 4115 cm³/hr (251 in³/hr)15 |

| Layer thickness | 0.028 mm (0.0011 in) |

| Printer’s dimensions | 825 × 620 × 590 mm (32.28 × 24.4 × 23.22 in) |

Carbon M2

Carbon offers unique CLIP technology which stands out for highly precise prints and a wide range of materials, including high performance, flexible resins. The M2 industrial 3D printer is an improvement to the previous M1 edition for its twice the build size, higher throughput, and lower production costs.

| Price | 50 000$ per year |

| Material | CLIP materials: Rigid Polyurethane (RPU), Prototyping Acrylate Resin (PR), Elastomeric Polyurethane (EPU), The Cyanate Ester (CE), Flexible Polyurethane (FPU) |

| Build size | 7.4 x 4.6 x 12.8 in (189 x 118 x326 mm) |

| Layer thickness | 0.075 mm (0.029 in) |

| Printer’s dimensions | 540 x 654 x 1734 mm (21.2 x 25.7 x 68.2 inches) |

ProMaker L6000

This industrial 3D printer by Prodways was designed for high volume production of small parts or complex large parts. The manufacturer promises highly detailed products at a fast speed. The printer actually has a very large printing bed, twice the size of its previous version L5000.

| Price | Starts at 250 000$ |

| Material | PLASTCure: Model 100, Model 300, Model 310, ABS 2800, ABS 3650, Cast 100, Cast 200, Clear 100, Clear 200, Rigid 10500 |

| Build size | 800 x 330 x 400 mm / 31 x 13 x 16 in |

| Layer thickness | 25 – 150μm / 0.001 to 0.006 inches |

| Printer’s dimensions | 2285 x 1266 x 2230 mm / 90 x 50 x 88 in |

Metal 3D printing: SLM technology

SLM technology was specially developed to produce metal alloys. Your objects are created layer by layer with metal powder locally fused in full melting process. The building chamber is filled with inert gas to keep the ideal conditions for melting the powder.

SLM Solutions

SLM Solutions has been developing their industrial 3D printers for the past 12 years, giving them a lot of experience and a good understanding of their clients’ needs. Their machines are available in different configurations, allowing for the best choice for your manufacturing needs.

SLM Solutions 500

This industrial 3D printer is highly recommended for the production of complex build parts. It has fully automated powder management which brings un the efficiency of the machine. It’s a powerful printer with a good size build size and easy solutions for powder removal.

| Price | Starts at 250 000$ |

| Material | Metal, such as Aluminium |

| Build size | 500 x 280 x 365 mm (19.7 x 11 x 14.3 in) |

| Build rate | Up to 171 cm³/h |

| Layer thickness | 0.02 mm (0.0007 in) to 0.075 (0.0029) |

| Printer’s dimensions | 5200 x 2800 x 2700 mm (205 x 110 x 106 in) |

SLM Solutions 280 2.0

SLM Solutions 280 2.0 was designed keeping high- performance manufacturing in mind. It has a smaller bed than the SLM Solutions 500 but comes in various configurations

| Price | Starts at 250 000$ |

| Material | Metal, such as Aluminium |

| Build size | 280 x 280 x 365 mm (11 x 11 x 14.3 in) |

| Build rate | up to 88 cm³/h |

| Layer thickness | 0.02 mm (0.0007 in) to 0.075 (0.0029) |

| Printer’s dimensions | 2600 x 1200 x 2700 mm (102 x 47 x 106 in) |

SLM Solutions 125

SLM Solutions 125 is the most compact out of the 3 industrial 3D printers. It is precise and economical, aimed for lower volume production of metal build parts.

| Price | Starts at 250 000$ |

| Material | Metal, such as Aluminium |

| Build size | 125 x 125 x 125 mm (4.9 x 4.9 x 4.9 in) |

| Build rate | up to 88 cm³/h |

| Layer thickness | 0.02 mm (0.0007 in) to 0.075 (0.0029) |

| Printer’s dimensions | 2600 x 1200 x 2700 mm (102 x 47 x 106 in) |

DMLS technology: metal sintering

DMLS 3D printing process works just like SLM, but at a lower temperature, the metal is not fully melted. That effects in shorter cooling time after the laser beam sinters the metal powder.

What makes the EOSINT M 280 printer so good?

We already mentioned the pioneers of 3D printers EOS. Turns out they produce not only plastic industrial 3D printers but also metal. The machine in concern uses DMLS technology and stands out for being the most reliable and advanced on the market.

It is compatible with different materials giving you a lot of options to choose from. It’s the right solution for parts that have complex architecture. We also use it to 3D print our client’s orders and we can surely say the parts are fully functional with a smooth finish.

| Price | Starts at 250 000$ |

| Material | Metal, such as Aluminium, Stainless Steel, Titanium, Nickel and Cobalt Chrome alloys |

| Build size | 250 mm x 250 mm x 325 mm (9.85 x 9.85 x 12.8 in) |

| Layer thickness | 0.1 mm (0.004 in) |

| Printer’s dimensions | 2500 mm x 1300 mm x 2190 mm (98.4 x 51.2 x 86.2 in) |

4 laser RenAM 500Q

British MAnufacturer Renishaw developed highly efficient industrial 3D printer RenAM 500Q with the technology of using 4 lasers at the same time. This improvement means significantly faster production and lower cost per part.

| Price | Starts at 600 000$ |

| Material | Metal, such as Aluminium, Titanium alloys |

| Build size | 250 mm x 250 mm x 350 mm (9.85 x 9.85 x 13.78 in) |

| Build rate | up to 150 cm³/h |

| Layer thickness | 0.075 mm (0.0029 in) |

ProX DMP 300 by 3D Systems

3D Systems an American industrial 3D printer producer and is very well known in the industry. ProX DMP 300 is highly recommended for manufacturing temperature resistant industrial parts that require also corrosion resistance. It also has an automatic recycling system.

| Price | Starts at 500 000$ |

| Material | Metal, Ceramic |

| Build size | 250 x 250 x 330 mm (9.85 x 9.85 x 13 in) |

| Layer thickness | 0.01 to 0.1 mm (0.0003 to 0.003 in) |

| Printer’s dimensions | 2400 x 2400 x 2200 mm (94.5 x 94.5 x 86.6 in) |

Upgraded ProX DMP 320

This industrial 3D printer is similar to the previous version, however, stand out for bigger build volume. It also comes with an optional external system and a second module for fast material exchange.

| Price | Starts at 650 000$ |

| Material | Metal, Ceramic |

| Build size | 250 mm x 250 mm x 330 mm (9.85 x 9.85 x 13 in) |

| Layer thickness | 0.01 to 0.1 mm (0.0003 to 0.003 in) |

| Printer’s dimensions | 2350 x 2300 x 2300 mm (92.5 x 90.5 x 90.5 in) |

Last but not least: Binder Jetting technology

Binder Jetting varies from SLM and DMLS and the two previous technologies use a sintering laser, whereas Binder Jetting is based on a binding agent. Between each layer, the metal powder is lightly cured for solidification.

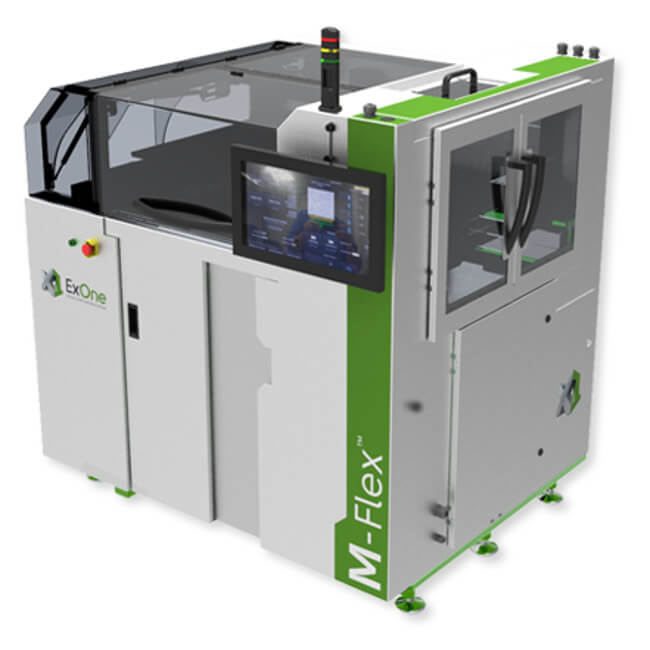

The well known M- Flex by ExOne

This industrial 3D printer provides you with great design freedom and the manufacturer claims it’s 10 times faster than the previous version. It’s fairly quick and is ideal for both end products and prototypes. The 3D prints are at a very good quality and level of details. We use this industrial 3D printer and it’s a relatively cheap metal 3D printing option for smaller and medium businesses.

| Price | Starts at 450 000$ |

| Material | Metal, such as stainless steel, steel, bronze |

| Build size | 400 x 250 x 250 mm (15.7 x 9.8 x 9.8 in.) |

| Build rate | 30-60 seconds/layer |

| Layer thickness | 0.1 mm (0.004 in) |

| Printer’s dimensions | 1675 x 1400 x 1855 mm (66 x 55 x 73 in) |

Larger volume with S-MAX

S-Max is also produced by ExOne, but compared to M’Flex has larger building bed, however, the layer thickness is bigger. Your choice should depend on your production needs and if you prioritize the complexity and level of details or the scale of your parts.

| Price | Starts at 1 000 000$ |

| Material | Metal, ceramics |

| Build size | 1800 x 1000 x 700 mm (70.9 x 39.37 x 27.56 in) |

| Build rate | 60,000 to 85,000 cm3 /h (2.12 to 3.00 ft3 /h) |

| Layer thickness | 0.28 to 0.50 mm (0.011 to 0.0197 in) |

| Printer’s dimensions | 6900 x 3520 x 2860 mm (271.7 x 138.6 x 112.6 in.) |

The whole 3D printing station

Ex One went even as far as investing in providing their customers with fully functional Additive Manufacturing station which includes two job boxes, mixer platform, operator panel, and access platform. With an enormous building bed, this industrial 3D printer is the monster ready for mass production.

| Price | Starts at 500 000$ |

| Material | Metal, ceramics, sand |

| Build size | 220 x 1200 x 700 mm x 2 / (86.6 x 47.2 x 27.6 in) x 2 |

| Build rate | 10.6–14.1 ft3 /h (300–400 L/h) |

| Layer thickness | 0.011 in–0.0197 in. (280–500 µm) |

| Printer’s dimensions | 329.9 x 158.7 x 194.9 in / (8380 x 4030 x 4950 mm) |

What if you don’t want to invest in buying an industrial 3D printer?

Sculpteo is an online 3D printing service and we do our best to give you the ultimate Additive Manufacturing experience. We provide you with a choice of 8 3D technologies and 18 materials to meet your production needs. Some of them are very strong and robust, others have high heat or chemical resistance.

Using an online 3D printing bureau can be very beneficial for your production. All you need is a CAD file. We take care of the whole production process for you, as well as post-production if required. And you simply get your ready to use parts delivered to your door. With us, your manufacturing process can be more efficient, faster and at a lower cost. You will also have absolutely new production possibilities.

Start 3D printing before your competitors do!

Investing in industrial 3D printers might be just what your company needs. With Additive Manufacturing you can produce your parts much quicker at a very high precision and complexity if needed. 3D printing also means less material waste and therefore is more cost effective.

But you can also start using Additive Manufacturing without purchasing an expensive industrial 3D printer. Using our online 3D printing service is simple, you just need to upload your CAD file. And if you have a project, but no 3D experience, we are also here for you with our design studio and can help to develop your ideas. Don’t wait any longer, contact us now!

Don’t forget to sign up to our Newsletter and follow us on Facebook to get the best 3D printing tips and tricks!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook