This Week in 3D Printing (17-25 Oct )

Posted By Alexia Toulmet on Oct 25, 2014 | 0 comments

As always, 3D printing made big moves this week. Here is a quick recap of the three news we preferred this week.

3D Printing was taken in the Time Capsule for 2064

Everyone can make a time capsule, with objects from childhood you can look at once you’re adult. But there’s something bigger about New York Historical Society’s one. They asked High Shool students to gather as many objects that should be contained to “pay it forward” to next generation of time-capsule explorers. Of course, people from 2064 will be able to find some books, newspapers, souvenirs, a Starbucks to-go-cup,etc. But it would have been representative of the 2014’s spirit without a 3D Print. That’s why they decided to put a small 3D printed World Trade Center in the box. We can’t help but wonder: will this print look as obsolete to the future generations just as it did for old photographs when we opened 1914’s time capsule?

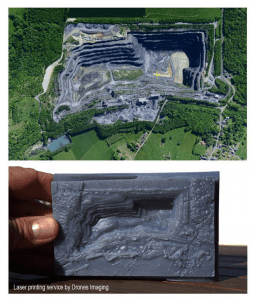

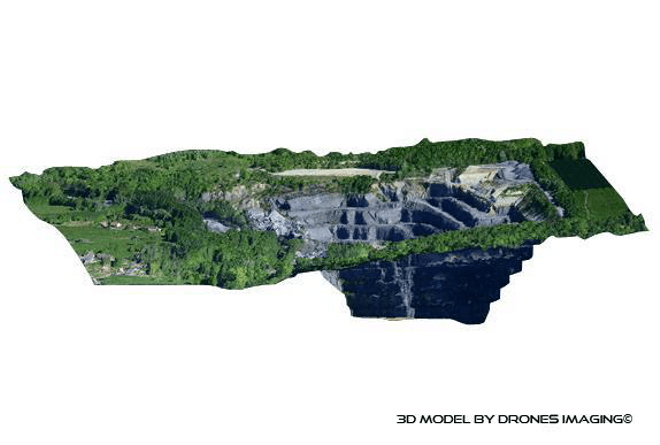

Using Drones and Photogrammetry provide Survey Data for 3D printable files

Collecting geological data is a really time consuming work. Now, this kind of operation can be simplified a lot by the use of drones. It also means 3D datas can be collected. That’s what the company Drones Imaging does, among other things: they use drone aircrafts to take over surveying projects. Photogrammetry allows them to create 3D printable models. Digital photogrammetry, the science of taking measurements from digital photographs, employs remote sensing and high-speed imaging to record precise positions of surface points in 2D and 3D. They ca use the collected data for public works, architectural, archaeological, and mining projects and has found it especially useful for acquiring data from areas that are traditionally more challenging to survey — rocky cliffs, for instance. Drones and 3D Printing definitely go along really well.

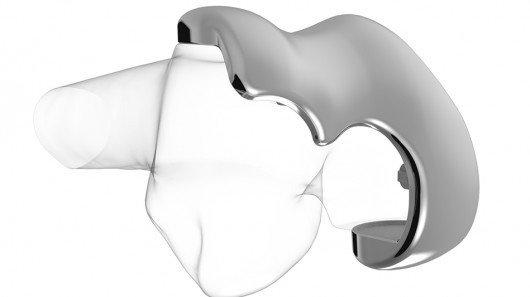

3D printing enables customized knee replacement surgery

3D Printing doesn’t stop from revolutionizing the medical sector. Every week brings its bundle of medical challenges met thanks to additive manufacturing. This week, it allowed to create knee implants, specifically adapted to each patient’s anatomy. The development could then help avoid complications that often follow the procedure, such as pain arising from instability of the joint. Another great news for the world of 3D Printing and medicine.

Sources :

Looking Forward to Looking Back: 3D Printed Object in Time Capsule for 2064

Industrial Drones and Photogrammetry Provide Survey Data for 3D Printable Models

3D printing enables customized knee replacement surgery

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook