How much does a 3D Printer cost VS a 3D Printing Service? Cost Analysis

Posted By Antu Nehuen on Jun 25, 2015 | 8 comments

It’s been over an year since the last study about 3D printing costs for personal and professional use so we have decided that a new, updated and improved version was necessary.

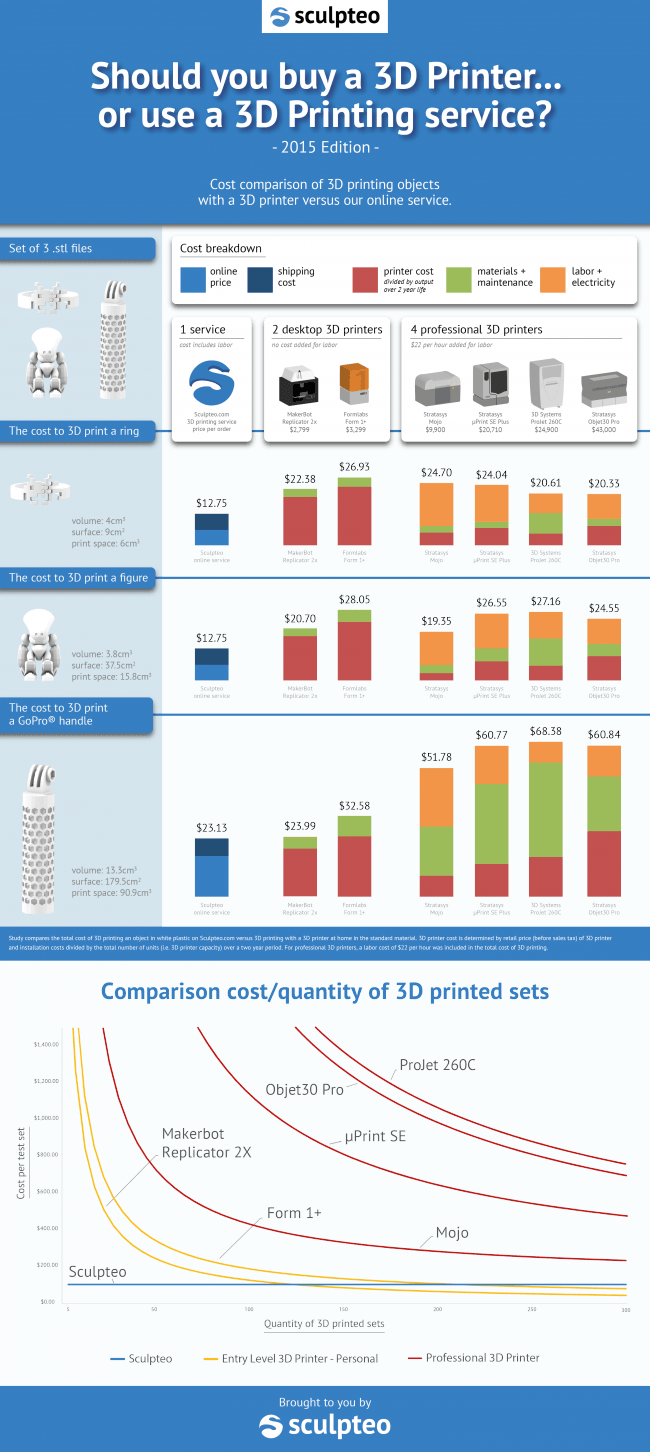

First of all we started with the basics; as 3D printing technologies evolve more and more printers become available and/or affordable and at the same time, some manufacturers seize the opportunity of an upgrade to increase their prices (or adopt proprietary consumables which results in the same). To achieve a fair comparison with last year results we use the same 3D designs but this time we also went a step further using a few other designs to show you a different approach to this costs analysis. For the initial part of this study we also used last year’s printers but with their newer version when possible (Form 1+ and ProJet 260C).

Finding the cost/print

The cost to produce an individual object will come up by simply adding up all the investment necessary + consumables + workforce divided by the number of objects printed over a 3 years period. This includes the current price of the printer (plus installation costs on professional printers), maintenance and replacement parts over 3 years, consumables and a person in charge of the printing process for professional uses (20€/h, same as last year).

Following some suggestions from last year’s readers we also changed two additional points:

- Sculpteo shipping: although including a unique shipping rate along all the study can be tricky given the variability of these numbers, we decided to move our hypothetical customer to the US and include the cost of an express shipping to achieve a more accurate final price.

- Previously the number of parts printed on each job of a personal desktop printer was dependent on the size of the object. This turned out to be unrealistic, as most users reported that they print exactly the part they need and not a large quantity of it “just because it fits on the printer”. In this new analysis, a desktop printer user prints a single object per job, saving time and money but reducing the previous number of prints over the 3 years period. On the other hand, professional users will print larger quantities to minimize costs while taking advantage of the usually larger build size.

Number of jobs and total parts considered

Here is where there is no other option than to take assumptions. For the selected printers and under different circumstances (personal or professional use) we considered the following workload:

| Printer | Type | Jobs/3 Years | Total parts / 3 Years |

| Makerbot Replicator 2X | FDM | 156 | 156 |

| Form 1+ | SLA | 156 | 156 |

| Stratasys Mojo | FDM | 300 | 600-2,400 depending on model size |

| Stratasys µPrint SE | FDM | 300 | 900-3,600 depending on model size |

| 3D Systems ProJet 260C | MJP | 500 | 2,000-10,000 depending on model size |

| Stratasys Objet30 Pro | PolyJet | 250 | 1,500-5,000 depending on model size |

| Sculpteo | SLS, SLA, MJP | ||

Is important to note that the number of job for the desktop printers is an average value based on a personal use. Arguably this number could be higher in cases like shared printers, power users or a commercial environments, but those cases are not a majority. Similarly, for some people 52 prints/year (once a week!) would exceed their needs, causing the price per part to increase. The question to be asked by a potential 3D printer owner is: “Am I going to be printing steadily every single week during a 3 year period?”

Yet another note on quality

People often say one should not compare apples to oranges and yet on many of these cases that’s exactly what we are doing (unfortunately). For the sake of simplicity and because quality is not always easily measurable we are leaving it aside, but it is important to remark a few things:

- Surfaces of objects printed by Selective laser sintering (SLS) and Stereolithography (SLA) are almost always smoother than Fused deposition modeling (FDM or FFF), even using professional printers on both sides.

- Thanks to the way objects are printed with SLS, there is also a significant advantage when it comes to print designs with big overhangs compared with FDM or SLA, as there is no need for additional support material at all.

- The strong layering effect on FDM objects (within the bulk material) often affects the mechanical strength of the part, despite using strong materials. This is significantly less of an issue on SLS prints and almost imperceptible on SLA prints.

You can read a bit more about these technologies here.

Materials and maintenance

Following last year’s study, material cost is calculated individually for each design and maintenance costs are estimated based on the experience of consulted users, ranging from 5% to 50% of the cost of the printer, and finally divided by the number of objects printed.

Labor and energy

Only for professional printing an added cost of $22/hour (€20/hour) was included. The operator-time consisted only on the time necessary to prepare the printing job and post-process the printed object at the end, not the printing time itself.

An additional energy cost of 0.18 $/kWh was considered although this contribution was negligible on almost all the printed items.

Another approach to the question

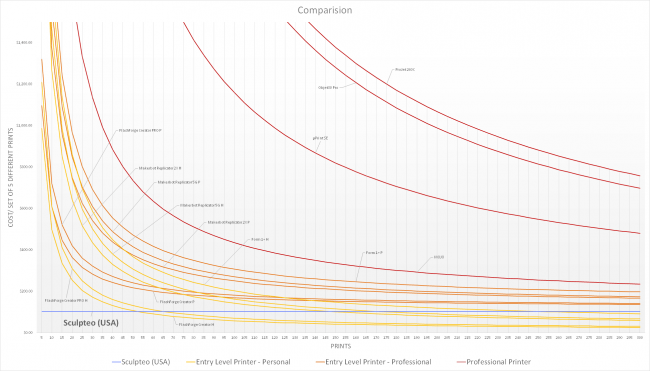

We believe it is safe to say that most people will print all sorts of objects, of different sizes and shapes. We also know that the number of prints over 3 years used so far, either 156, 300 or 500 is just what we found to be most accurate for an average user, but.. “on average nothing is average” so what if we could free all these factors and still get some useful information?

5 Designs selected

Space Invader ring by Geekrings, Robot mini-figurine by Emmanuel Eymond, GoPro grip mount by Fabrice, Windmill by fclem33, Brain Gear by mitchlee11

To do this we grouped 5 of our previously used designs and calculated the cost to print each set of 5 for a number of different printers depending on how many copies of this set are printed. As more and more items are printed, the investment dissolves on all of the prints, making each of them individually cheaper to produce. On the other hand, there is a (approximately) constant cost/print for the consumables required.

(For this analysis, each of the 5 items of the set is shipped separately)

This way of seeing the problem allow us to easily find what option fits your needs better from a strictly financial point of view. Just be careful not to get ‘orange’ when you tried to print ‘apple’ 😉

Conclusions

Although this is not a simple analysis if one pretends to consider even the slightest detail, we went to great lengths to be as comprehensive as possible. We found that there are options out there for the people who needs to print extremely cheap, regardless of anything else, as well as options for people with unrestricted budgets aiming for the best possible quality. But it also seems clear that online services like Sculpteo can offer a bit of both worlds, with the added simplicity of not having to deal with often rather complicated devices nor spending a good time in the process.

All the calculations and automatic plots are available here

(It’s a Excel 2013 file which can be opened with older versions but some visual differences may appear)

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook