Professional vs Personal 3D Printing Benefits: how 3D Printing can enhance our daily lives

Posted By Eole Recrosio on Sep 21, 2016 | 0 comments

Have you ever had this discussion with people about what to do with the 3D printing technology? Did you ever ask yourself what 3D printing can bring into our lives? As a professional, can you imagine how far the technology can improve both your efficiency and your customers’ satisfaction?

At Sculpteo, we are thinking about it every day. 3D printing, and especially the access to online 3D printing services, allows private individuals and professionals to go from an idea to an object faster, and to fulfill specific needs more easily, at a lower cost: all you need is a 3D file, and an idea of the design restrictions for the material you’ve chosen. Then, in a few clicks, you order, and receive your parts a few days later, or have them sent directly to your customers. It’s so simple that it’s sometimes difficult to understand. That’s why today we’ve put together a few examples of how 3D printing allows you to design what you need, create what doesn’t exist, and move forward in education and medical care, at the private and professional levels. This way, you’ll have examples to quote in case you’re asked what 3D printing is about, and how it can be used in our daily life.

If It Does Not Exist: Design It

As private individuals:

A month ago, I bought some vacuum packed bags to transfer my summer clothes to warmer ones into my closet. When came the time to use them, I found out that they did not fit into the end piece of my high-tech Dyson vacuum. I searched for a traditional solution on existing accessories and replacement parts but nothing was close enough to satisfy my demand. Then I thought about 3D printing. I designed myself with my own measurements a connector to fit into the vacuum and sent the model to an online 3D printing solution to finally receive an item that perfectly suited my expectations.

As professionals:

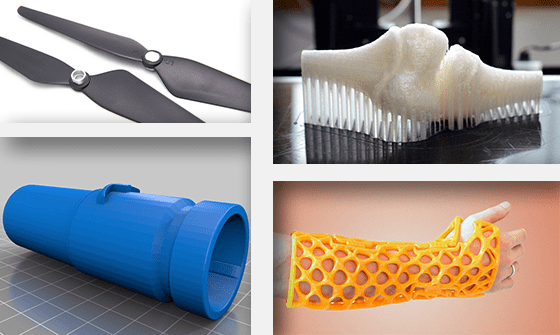

Along the same lines, 3D printing allows professionals new innovative ways to satisfy customer expectations to a common household matter. One good example is: the end of the toothpaste. From a need (not wasting the end of the toothpaste tube), the guys behind Squizmo found a way to deal with the rest of the toothpaste inside the tube. They were thinking about a small and clever device to allow them to seal a tube after they had refilled it. That’s why they naturally thought about 3D printing. At the same time, they fulfilled their expectations and solved a common problem. Not only do they offer the opportunity to buy a 3D printed Squizmo, but the chance to print it yourself if it breaks thanks to the supplied 3D model.

The Squizmo Squeezing a Tube

Create It Yourself

As private individuals:

This summer, a friend visited me and brought his new drone. We decided to go out for a fly and landed the device in a clear area. After a couple of minutes, it began to twitch and suddenly crashed against the floor. The hit wasn’t hard enough to break it completely, but one of the propellers broke in pieces. We just went back home and tried to order a new one online. The manufacturer was only shipping to his own country, and the overall cost was almost the price of a new drone. As a result, we decided to look into 3D printing. We found on an online library store a plan that perfectly fit the old propeller and we placed the order. 72 hours later, the new one was installed and for a negligible cost. We ordered three more to be prepared for the drone sessions to come.

As professionals:

It was not as easy for the team from Antsy Labs. As their Fidget Cube Kickstarter campaign was growing, they were facing a thousand questions from all around the globe about this little piece of plastic designed to help people control their anxiety. They explained how 3D printing helped them design and push their ideas into their hands. From each drawing attempt, they were 3D printing a cube to make sure everything was working. As they noticed it, the Fidget Cube could not have come to life without this process. As the prototypes were getting complex and closer to the final design, they had to have a working prototype in hands to make sure everyone feel good about both working parts and design. From the proof of concept to the final product and thanks to the amazing funding campaign, Antsy Labs created a huge need for everyone to fidget a little bit.

The Fidget Cube from Antsy Labs

3D Printed Science

As private individuals:

In North India, near New Delhi, high-school students are taking a science course on the human body. Instead of buying the traditional Oscar the skeleton, the head teacher decided to equip the school with a 3D printer. Students are carefully watching the plastic bones and human cells being printed to life.

“To see a practical demonstration of a physics concept like friction, we asked students to make a skateboard”, he explains. We can eventually go further and imagine the whole learning process engaged into the 3D domain, the manufacturing process and how a concept is applied to real life.

Exit cardboard cut-outs and old plastics course materials, hello 3D printers. With the growing demand of unique and customized designs, India started to drive its education on the way of 3D through animation and industrial uses.

As professionals:

We can also think about the thriving potential in the prosthesis and orthosis field. A large amount of these were printed inside hospitals to answer an urgent demand. Combined to a 3D scanner, a 3D printing tool can fill any need. The project Daniel is one of the most promising humanitarian projects related to 3D printing. Thanks to local Sudanese Fablabs or imported printers, health volunteers can 3D print functional and adjusted prosthesis to war wounded people. The overall cost is about $100 and can be even more reduced as the technology and techniques progress. Another example is of course Unyq, the personalised prosthetic cover creator, that provides customized prosthetic covers and braces, to go from “stigma to style”, a project made possible and affordable by 3D printing. They were recently featured at a White House event promoting inclusive design.

UNYQ team at the White House wearing UNYQ Align™ scoliosis white brace. (Photo: UNYQ)

Those examples encourage the idea of more common use of 3D printing in our everyday lives for hobbyists and the general public as well as professionals.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook