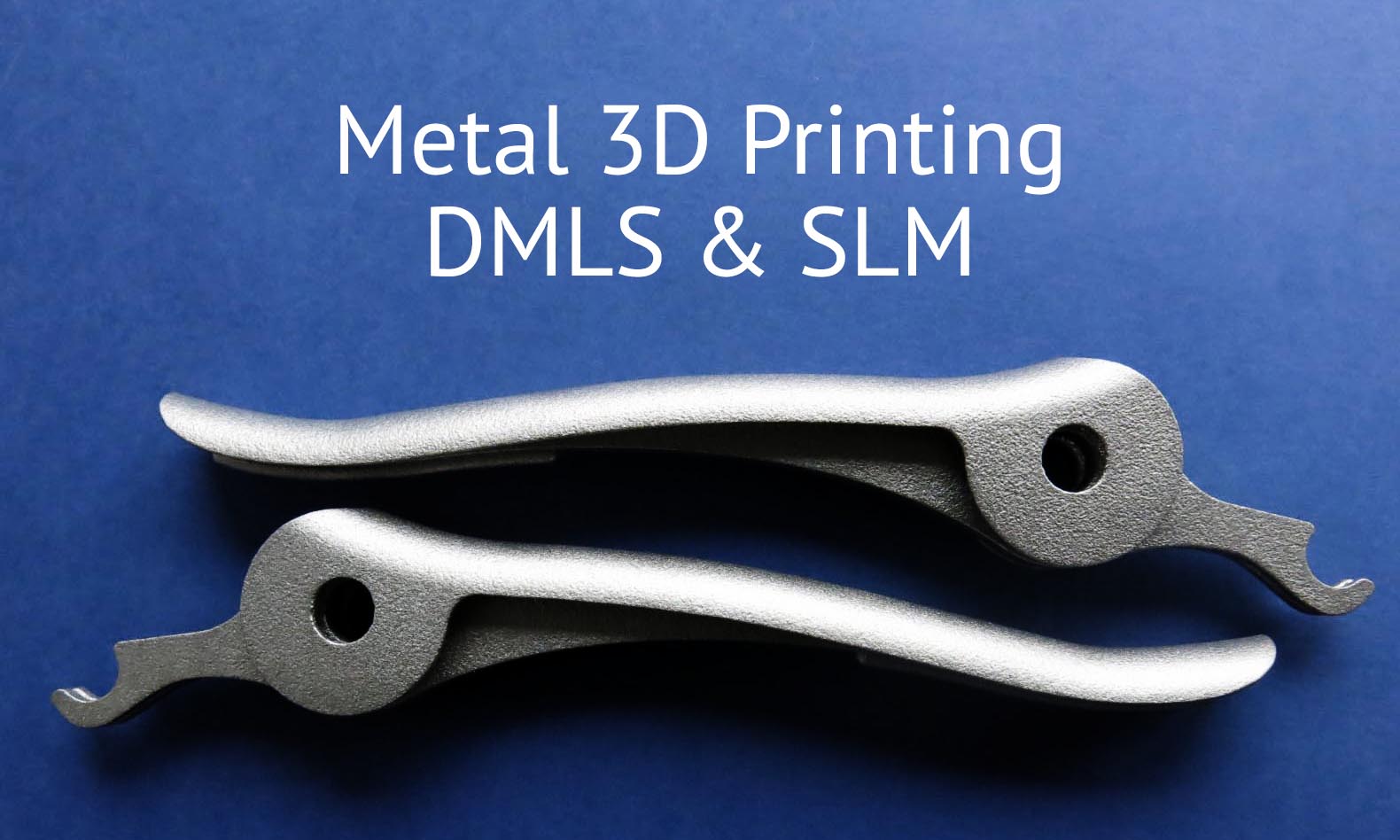

3D Printing Aluminium, Stainless Steel, and Titanium with the DMLS and SLM technologies

Posted By Hannah Bensoussan on Jan 5, 2017 | 0 comments

Metal 3D printing is now available on our online 3D printing service, with the DMLS and SLM technologies! By putting our expertise and intuitive platform at the service of 3D Printing Aluminium, Stainless Steel, and Titanium, we are opening new possibilities for the manufacturing of high-quality parts. Learn all about this new offer in 7 questions.

Why is an online Metal 3D printing service a big deal?

Metal 3D Printing is gaining popularity in manufacturing, and not only in the fields of aeronautics and aerospatial, and of medicine. It allows the fast production of high-quality functional parts with geometries that would be impossible otherwise. It fosters innovation by enabling new ways to conceive parts, with lighter, more intricate shapes.

But metal 3D printing is complex: it goes along with specific constraints, especially thermic and structural ones. That’s why making metal additive manufacturing available online, as a service, is essential: it frees businesses from having to worry about the operating of the machines. Our service will also provide the necessary support and advice on how to design your objects so that they are optimized for laser melting printing, thanks to the expertise of our metal dedicated team, and to our new software suite for metal 3D Printing: Agile Metal Technology (more on this below).

Didn’t Sculpteo offer metal 3D printing already?

Yes, we already provided silver and brass 3D printing, but it doesn’t use the same technology. These two metals are 3D printed using lost wax metal casting, whereas our new service uses DMLS and SLM, for three new materials: Aluminium (SLM technique), Titanium (DMLS) and Stainless Steel (DMLS).

What’s the difference between the powder bed techniques (DMLS and SLM) and metal casting?

In lost wax metal casting 3D printing, the object that is 3D printed is actually a wax model of the object, not the object in metal itself. The model is then used to create a cast, in which the metal is poured. The objects thus created are not as strong as objects fully 3D printed in metal, and are mostly used for aspect (in jewelry, for example).

The DMLS and SLM techniques are closer to the SLS technology, that we use for plastic: metal powder is locally sintered (in Direct Metal Laser Sintering) or melted (in Selective Laser Melting) by a laser, layer by layer, to create the object according to the 3D CAD model.

These two 3D printing technologies create fully functional metal parts, with much higher accuracy than lost wax metal casting can provide. The objects have a better strength and can be used as mechanical parts, exactly as metal parts produced with traditional manufacturing techniques. These technologies are used in many applications. Aeronautics and aerospace have been the first industries to have a wide usage of metal 3D Printing (as you can read in this article), but many other industries are already using it for tooling, masters for molding or producing end-use parts.

Which metal 3D printing materials and finishes are available?

You can now 3D print 3 metals, directly online, on our platform:

- Aluminium AlSi7Mg0,6 (SLM technique)

- Titanium TiAI64V grade 5 (DMLS technique)

- and Stainless Steel SS316L (DMLS technique)

For now, the 3 materials are offered with raw finish: the supports are manually removed and the parts are blasted.

My project is more complex that producing raw parts – can I talk to a human?

Metal 3D Printing is a serious challenge. That’s why we created at Sculpteo a dedicated metal team that combines modeling and engineering skills to help you on your project. Based on your requirements of accuracy, the function of your part, we will advise you the best design and the best material. We are able to study and quote your project on demand for the following materials:

- Maraging Steel

- Stainless Steel: SS17-4 or SS15-5

- Titanium Ti6AI4V grade 23

- Cobalt-Chrome CoCrMo

- Inconel Alloy 718

- HastelloyX

We’ll establish the most appropriate finishing strategy for your specifications, such as:

- polishing

- grinding

- turning

- milling

- drilling

- threading

- heat treatment

If you are planning to print short series, we strongly recommend you to contact us – even if you need raw finish. We’ll come back shortly with good technical advice.

How can I know if metal 3D printing is best for my application?

Metal 3D printing can be quite costly and complex, and doesn’t fit every application. To advise you on your 3D printing projects, check feasibility, optimize your design and establish the most appropriate finishing strategy, we are creating the Agile Metal Technology Suite.

This suite, and in particular, its first tool, Agile Metal Business Case, will help you figure out whether metal 3D printing is best for your project, and, if it’s not, which aspects of it you should change to make it work.

What is the Agile Metal Technology Suite and the Business Case tool?

To be more precise, the Agile Metal Technology Suite is a group of 6 tools for metal 3D printing:

- Agile Metal Business Case, which is already available: an Artificial Intelligence that will audit your additive manufacturing project and give you recommendations and actionable advice. To learn everything about Business Case, click here.

The 5 other tools are still in development and will be released in the next months:

- Smart Design Optimizer helps you make sure your design is optimized for metal 3D printing, in particular when it comes to thermal constraints.

- Automatic Lattice Generator helps you to optimize your design by proposing lattice structures depending on the forces applied to different zones.

- Support Generator helps you to choose the most appropriate support strategy for metal 3D printing.

- Post-Processor helps you assess the best finishing strategy.

- Batch Control for Metal helps you reduce your series cost.

All of the tools are more detailed in the Agile Metal Technology article, and the first tool, Agile Metal Business Case tool, is explained in details in this article. You can also try it out right away!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook