3D printing in very smooth polyamide thanks to the smoothing Beautifier

Posted By Hannah Bensoussan on Jan 25, 2017 | 0 comments

Do you know the Smoothing Beautifier? It’s the patent-pending process that our R&D team developed to make polyamide 3D prints as smooth as injection moulding parts. We are now taking this innovative 3D printing finish out of its beta phase, and making it available directly online. The new version of our smoothing beautifier is shinier, more performant, and available for black died objects.

Learn everything about this new offer!

What’s the Smoothing Beautifier process?

Smoothing Beautifier is a chemical treatment that smoothes the parts after their 3D print is complete. It is an additional finish for your 3D printed part, and it allows to achieve a very smooth surface, both in aspect and texture.

What benefits does it bring to my 3D printed parts?

This finish was designed to narrow the quality gap between 3D printed parts and injected molded parts. Indeed, one of the main limitations of 3D printing is the rough surface finish that it provides. With smoothing beautifier, the surface is as smooth as injection molded parts, which opens the door for new applications.

What’s different with the new Smoothing Beautifier version?

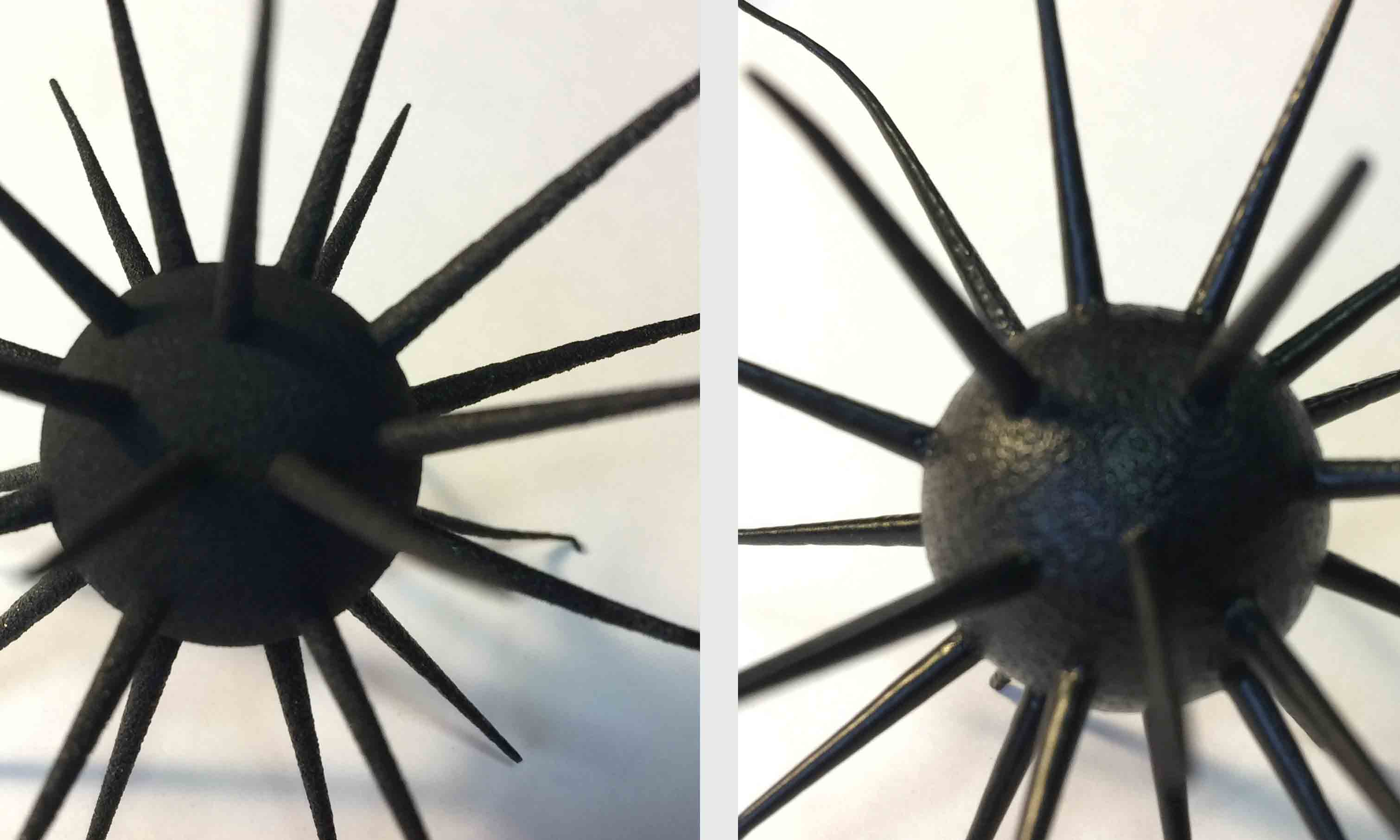

The first version of the Smoothing Beautifier was offered as a Beta Program in May 2016. In the past few months, we’ve experimented on this technique, and we’ve made it more efficient. In particular, it now provides an even shinier surface.

We’ve also learnt more about its limitations, and have overcome some of them. For example, it used to be difficult to processs long, flat surfaces, and it’s now much easier.

Can I use Smoothing Beautifier for all kind of 3D prints?

No. With this process, we can only smooth parts that have been manufactured in polyamide PA 12, in white powder, with the SLS (Selective Laser Sintering) technology.

Other materials (black powder SLS and grey powder SLS, all resins, metals and composites) and technologies (DMLS, SLM, CLIP, Polyjet, Multicolor,…) are not yet available with the smoothing beautifier.

Can I use Smoothing Beautifier with colored parts?

This is a new feature: you can now dye in black your smoothed parts! It even improves the aspect of your part even more.

Other dyes and all paints are still unavailable. Black powder polyamide and grey powder polyamide are also unavailable.

Are there design constraints for smoothed parts?

Yes! If you intend to use the Smoothing Beautifier on your part, you need to keep the following elements in mind.

Maximum size for Smoothing Beautifier

The maximum dimensions are 140x120x90 mm.

Specific shapes

Because of the nature of this 3D printing finish, some shapes should be avoided.

- Sharp angles and small details will be smoothed down during the process. They won’t disappear, but they might be lightened and become less visible.

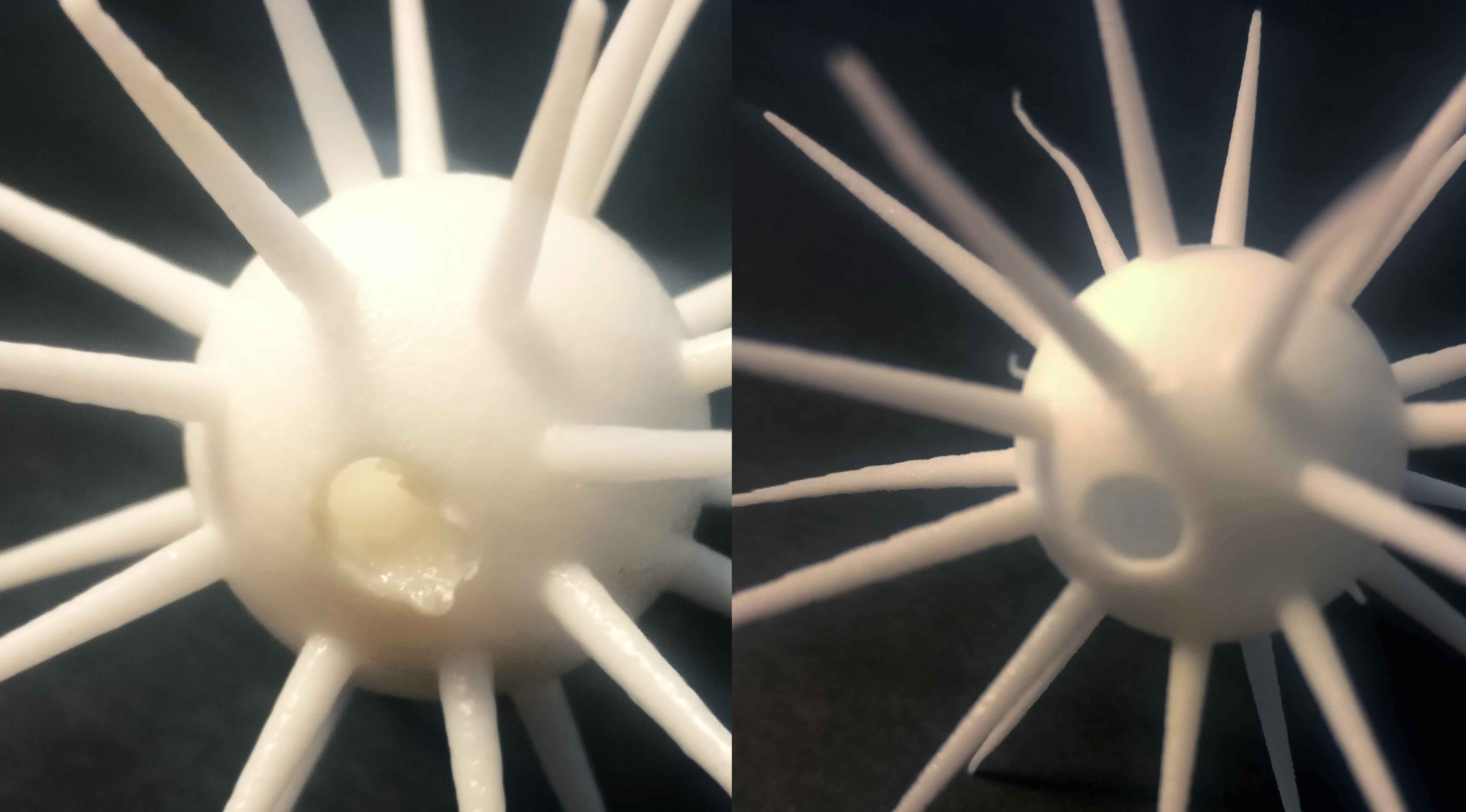

- Hollow parts can’t be smoothed with the smoothing beautifier. It would cause an irregular hollowing hole, as you can see below. Because we are committed to providing the best quality possible, we do not accept hollow parts for the smoothing beautifier process.

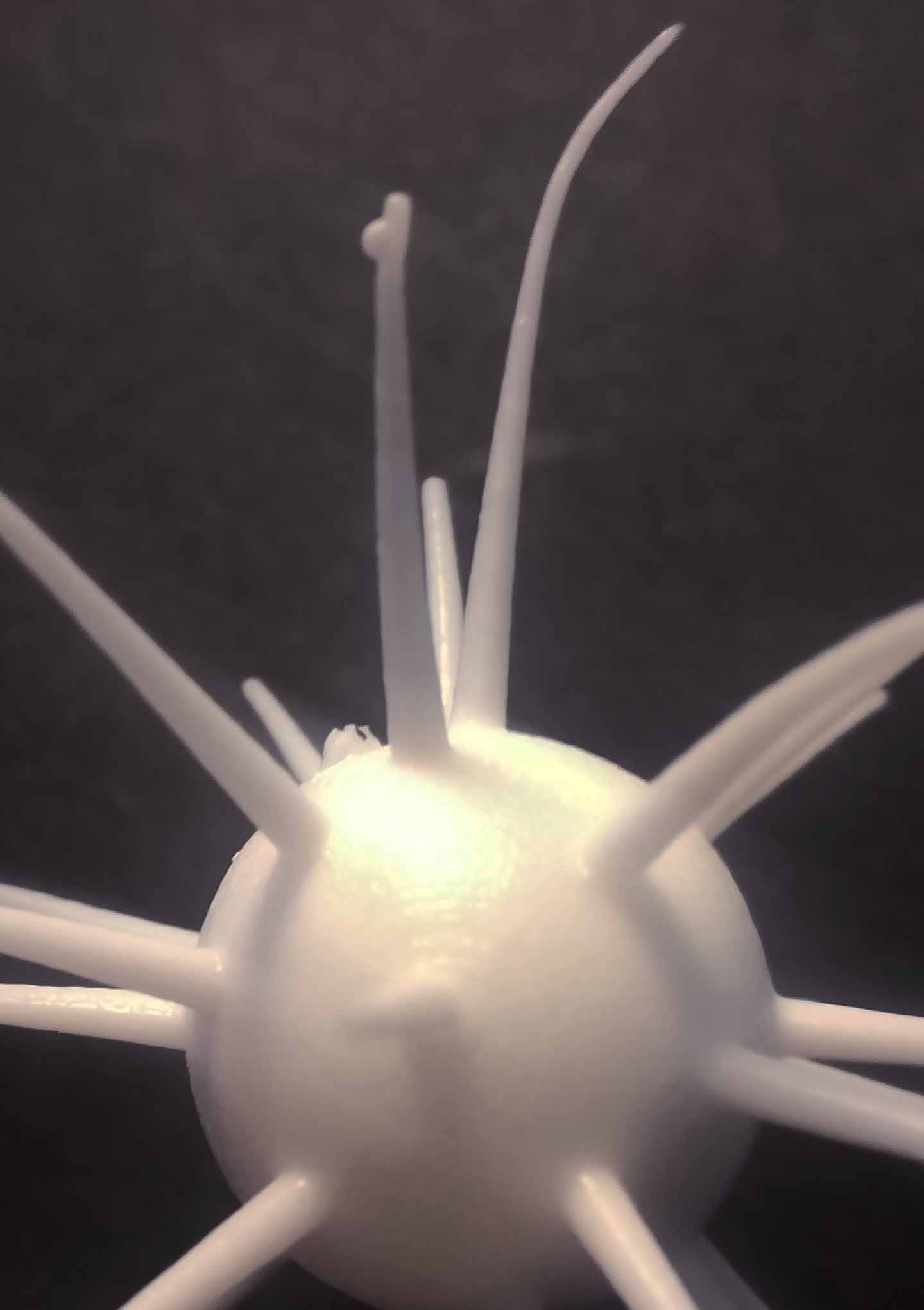

- Long thin parts run the risk of being deformed during the process, especially if they are on both sides of the object. As you’ll see below, the extremities of the long part are bent, and can even have droplet-shaped deformations:

Here are some more images of 3D printed objects which were made smoother to the eye and to the touch with our Smoothing Beautifier 3D printing finish:

We hope this new version of the smoothing beautifier will inspire you to create high-quality objects with 3D printing!

You want to learn more about our high quality 3D printing finishes? Read our finishes page, and our blog article about our new painting options.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook