Metal 3D Printer: Manufacturers and Models of 2017

Posted By Eole Recrosio on Feb 14, 2017 | 3 comments

Which 3D printers are used for metal 3D Printing? At Sculpteo, we use powder melting technologies to create your metal parts in aluminum, stainless steel and titanium with a SLM280 and a EOSINTM280. In the industry, there are many more machine manufacturers using different technologies and materials. This article will give you a list of the main manufacturers and 3D printers, sorted by technologies.

Direct Metal Printing

The technologies we use at Sculpteo are Direct Metal Laser Sintering and Direct Laser Melting. These powder bed technologies are using a powerful laser and a powder feedstock to create 3D printed objects. You can learn more about the metal 3D printing technologies by downloading our free Complete Guide of Metal 3D Printing.

EOS

EOS is a German manufacturer that provides machines and materials for both plastic and metal 3D printing. Here is the list of their machines for metal 3D printing:

- EOS M100: entry model for metal 3D printing

- EOS M290: first production model of high-performance metal parts

- EOS M400: Industrial production model for large metal parts

- EOS M400-4: Faster version of the M400

- EOSINT M280: The model used by Sculpteo to 3D print your titanium and stainless steel parts. This model is a Direct Metal Laser Sintering machine.

- Precious M080: this one is used for high-quality precious metal 3D printing.

SLM Solutions

SLM Solutions is also a German manufacturer providing metal equipment for the industry. Their machines exclusively use a full melting process of the powder feedstock.

- SLM 125: the entry model that provides fast and compact metal 3D printing objects

- SLM 280 2.0: mid-range segment machines that allows metal parts into production. It is the machine we use at Sculpteo to 3D print in aluminum.

- SLM 500: Contains a multi-beam technology for fast production and a very large building envelope for industrial uses.

The SLM 280 Machine used by Sculpteo to 3D print Aluminum

3D Systems

This manufacturer is the precursor of additive manufacturing: their founder, charles Hull, holds one of the earliest 3D printing patents, the patent for stereolithography.

- ProX DMP 100: first model for small high quality metal 3D printing objects

- ProX DMP 100 Dental: the dental model enables to use the technology for metal dental prostheses

- ProX DMP 200: allows faster and larger metal 3D printed parts than the DMP100 model

- ProX DMP 200 Dental: this model offers Cobalt Chromium material for dental prostheses.

- ProX DMP 300: industrial production model for metal 3D printing

- ProX DMP 320: an upgraded version of the DMP 300 model

3D Systems Direct Metal Printing 320

Trumpf

Yet another German 3D printing company that provides metal 3D printer. Trumpf is also manufacturing with laser metal deposition and laser welding.

- TruPrint 1000: entry model for powder-bed based laser melting

- TruPrint 3000: large production model for laser metal fusion process.

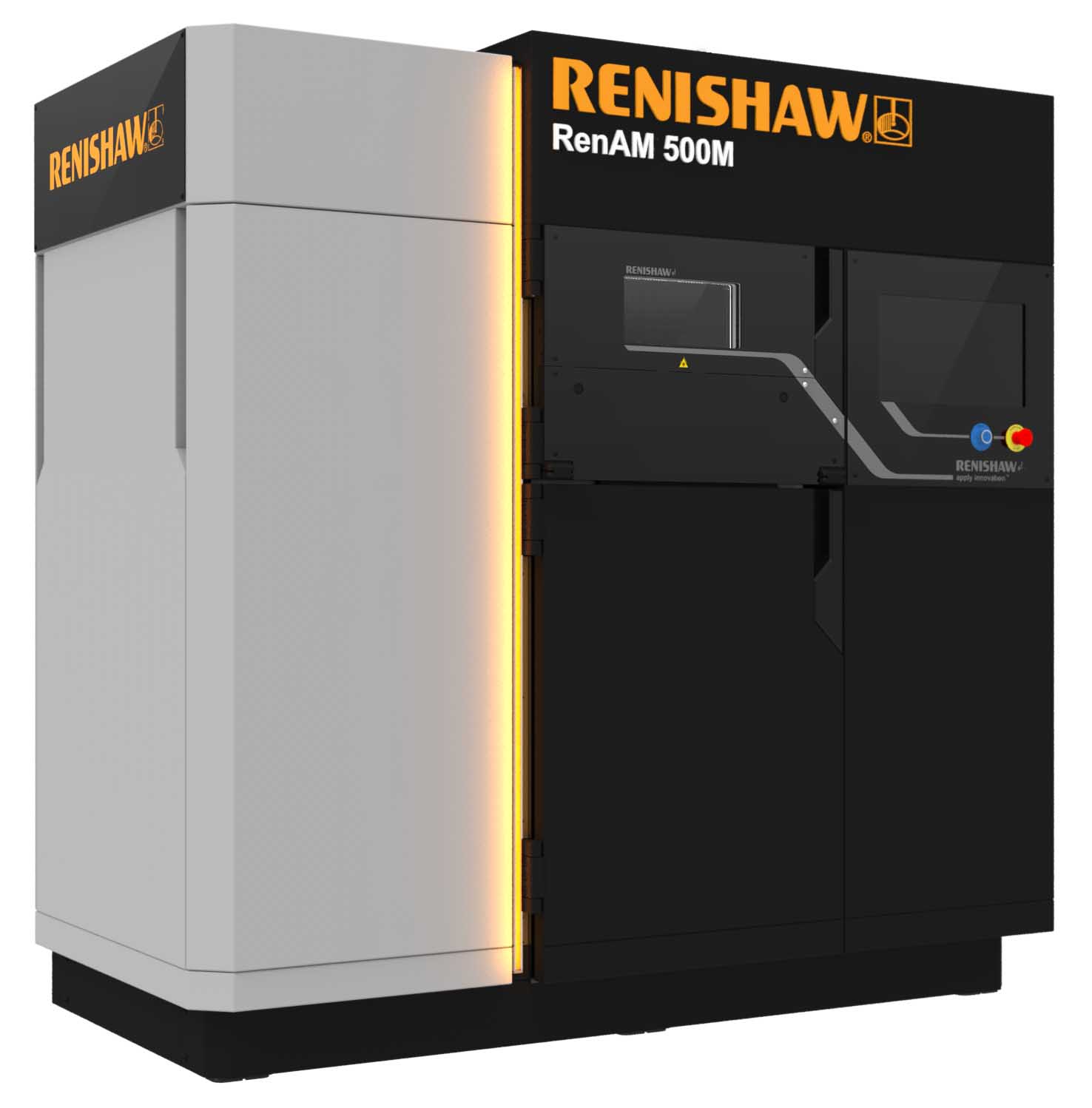

Renishaw

This British engineering company builds additive manufacturing solutions with powder-based technology.

- RenAM250: industrial entry model for direct metal additive manufacturing

- RenAM400: higher version of the AM250 model. More powerful laser and larger building volume.

- RenAM 500M: the industrial production model for metal additive manufacturing improved with automated features for the industry.

The Ren AM500 M

Electron Beam Melting

The Electron Beam Melting technology works with a powder bed feedstock and computer-controlled electron beam as a power source. This technology allows very fast production thanks to the multiple electron beams. However the building volume is smaller than the direct metal printing. To learn about this technology, check our glossary page or our Complete Guide of Metal 3D Printing.

Arcam

- Arcam Q10plus: model designed for medical purpose

- Arcam Q20plus: model designed for aerospace components

- Arcam A2X: R&D model for aerospace and titanium alloys.

Sciaky Inc, an additive manufacturer has made an in-house model called the EBAM 3000. This model combines the Electron Beam technology and the laser deposition to create metal parts.

Direct Energy Deposition

The direct energy deposition technology is a combination of welding and additive manufacturing. It allows very fast and large scale metal parts mainly for aerospace and engineering purposes. To get more information about this technology, get our free ebook about metal 3D printing.

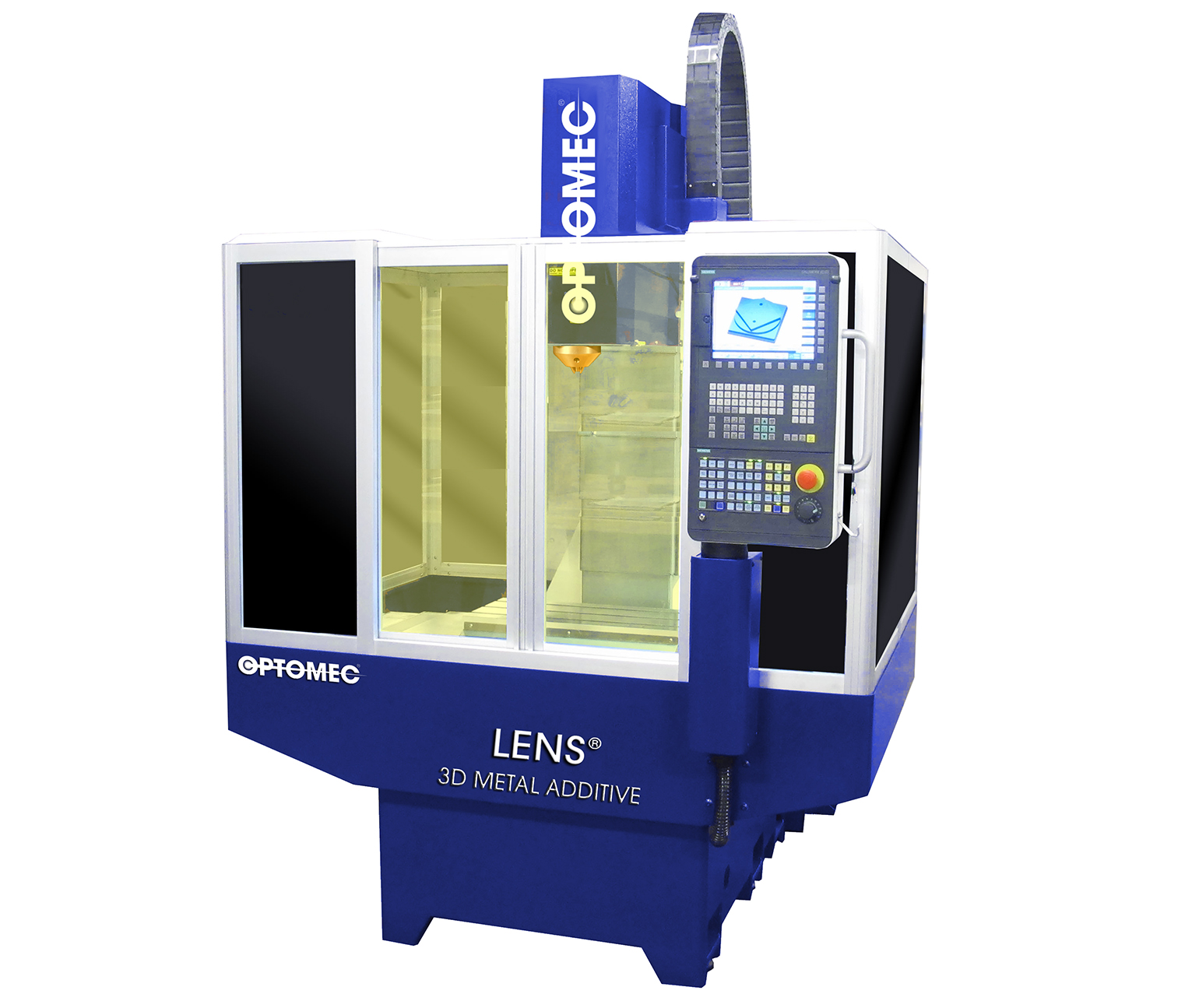

Optomec

Optomec provides manufacturing solutions from the US with direct energy deposition technology. Their LENS project was one of the first DED patents of the metal additive manufacturing.

They offer 3 range of machines:

- The classic lens program

- Lens 450: Low Cost Entry Level System

- Lens MR-7: Material Research & Prototyping System

- Lens 850-R: Large Part Repair System

An Optomec Machine from the LENS program

- The Lens Print Engine for integration with CNC-machine and industrial purpose

- The Lens Machine Tool series for metal hybrid and additive manufacturing.

Trumpf

- TruLaser Cell 3000: This machine is built for compact but precise 3D printing objects but also welding and cutting. It has a 5-axis platform to produce prototypes or larger series.

- TruLaser Cell 7000: This improved model allows three dimensional cutting, welding and laser metal deposition. You can work with multiple components simultaneously.

Binder Jetting

The binder jetting technology allows very large, fast and cheap 3D printed objects. The objects are however less strong, usually fitted for aesthetic uses such as jewelry. It relies on a liquid binding agent deposited by one or more inkjet heads on a powder feedstock. The object is then cured to give solidity and evacuate the binding agent. You can learn more about the binder jetting technology on our glossary page or in our new free ebook on metal 3D printing.

The S-Print Machine by ExOne

ExOne

Exone is the main manufacturer of the binder jetting technology. It offers very large machines and possibilities for industrial integration.

- Exerial: industrial production of metal molds

- S-Max: Very efficient in-production machine

- S-Max+: Same as S-Max with a very large build platform and mold option

- S-Print: compacted model for improved productivity

- M-Print: Industrial size model for metal 3D printing

- M-Flex: complete solution for metal additive manufacturing produced in record time

These are the main machines and manufacturer of the metal additive manufacturing industry. If you want to discuss about it, please leave us a comment.

If you liked this article, please feel free to share it on Facebook, Twitter and Linkedin

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook