Carbon : FPU CLIP Resin is Available on Sculpteo

Posted By Eole Recrosio on Mar 15, 2017 | 0 comments

All the CLIP resins are now out of our BETA program, and directly available on our online 3D printing platform! The Flexible Polyurethane (FPU) is now available for all our users on our interface. In this article, find out all you need to know about Flexible Polyurethane and the other CLIP resins: how to use the resins and how to design with CLIP.

What is CLIP

CLIP stands for Continuous Liquid Interface Production. CLIP is a unique photochemical process developed by Carbon that carefully balances between light and oxygen to rapidly 3D print resin parts. It works by projecting light through an oxygen-permeable window into a reservoir of UV curable resin. As a sequence of UV images are projected, the parts solidifies and the build platform rises.

The CLIP resins are technical engineering materials that enable the production of prototypes and functional parts in many industries.

Carbon CLIP Engineering Resins

Thanks to the Carbon M1 machine, we can produce object in FPU and 4 other 3D printed mechanical resins:

- The Rigid Polyurethane (RPU) is the most robust CLIP resin. It is very stiff and strong with material properties that outperform ABS plastic and rivals Nylon. This material is perfect for mechanical parts that need to be tough, heat-resistant, and abrasion-resistant.

- The Prototyping Acrylate Resin (PR) comes in 6 different colors that can be mixed on demand to create smooth and shiny prototypes. PR can be used for both visual and functional prototypes of end use products.

- The Elastomeric Polyurethane (EPU) is a high performance rubbery material. It exhibits excellent elastic behavior under cyclic tensile and compressive loads. EPU is useful for demanding applications where high elasticity, impact, and tear resistance are needed such as cushioning, gaskets, and seals.

- The Cyanate Ester (CE) is a special resin with a very good glass transition temperature (up to 225°C [437°F]). Marked by stiffness and long-term thermal stability, CE is useful for under-the-hood applications, electronics, and industrial components.

Flexible Polyurethane (FPU) CLIP Resin

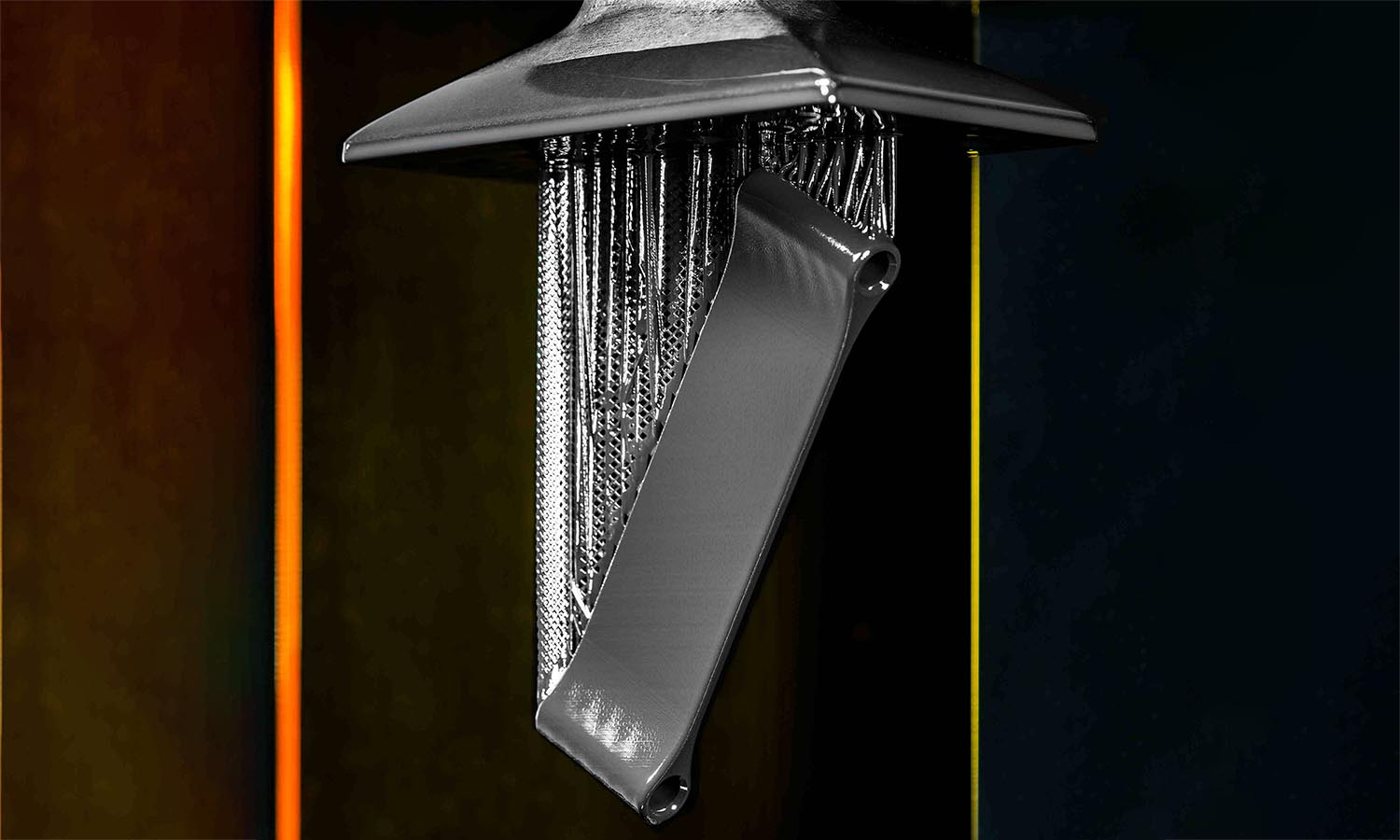

Our FPU resin is a black semi-rigid material with good impact, abrasion and fatigue resistance. The final material has a black colored and smooth surface. The object has to be cured to obtain its final mechanical characteristics.

How to Use the FPU CLIP Resin

FPU is a material close to the injection-molded polypropylene. It is excellent for housewares, toys, rigid packaging, living hinges, and anything that requires a lightweight and flexible plastic material. On the other hand, FPU is not an elastic rubbery material as EPU. It cannot be used for seals.

Design rules

With 3D printing, CAD design requires some specific rules and guidelines to be followed. Each material has its own design guidelines you can find on the adequate material page.

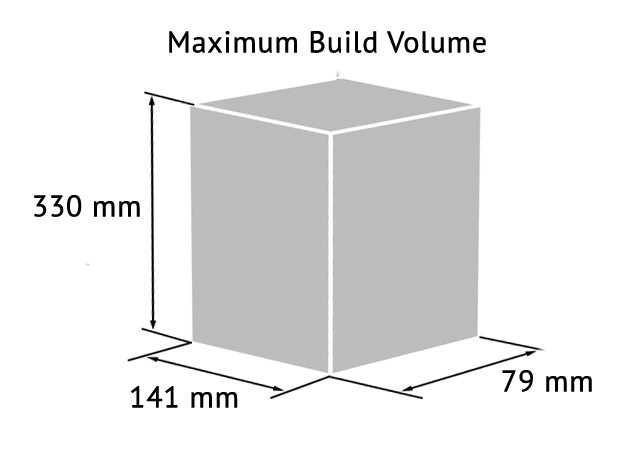

The Carbon M1 3D printer allows to print with a layer thickness of 0.1 mm (100 µm) in a building volume of 144 x 81 x 330 mm (5.7 x 3.2 X 12 in).

With CLIP resins, it is recommended to avoid wall angles above 40 degrees as it will need to be supported by extra supports. When a part is self-supported, it uses less resin, it is 3D printed faster and requires less post process (as less supports need to be removed).

Sharp angles are also to avoid when designing with CLIP. It is better to smooth them and to add fillets or ribs to support and smooth 90° angles.

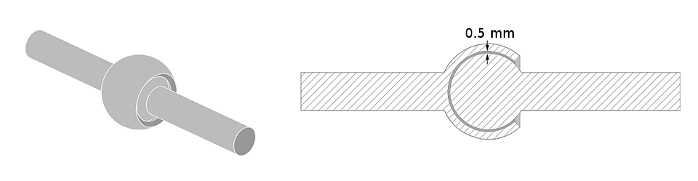

Minimum thickness of the walls for the FPU resin is 0.5 mm. At this thickness, the object will be quite flexible. If you need to be sure your object will be both flexible and resistant, you’ll need a minimum wall thickness of 0.8 mm. For the object to be fully rigid, a 1.0 mm wall thickness is required.

To learn more in depth about the thickness and geometry guidelines, please check this section on the FPU material page.

If you liked this article, please feel free to leave a comment and to share it on Facebook, Twitter and Linkedin

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook