Multicolor 3D printing: How does Multi color 3D Printing Work and What Is It For?

Posted By Hannah Bensoussan on Mar 22, 2017 | 0 comments

What are the options to 3D print in colors? Of course, you can paint a monochrome part created with SLS (Selective Laser Sintering), SLA (Stereolithography) or another technology. You can also use a multi-nozzles FDM (Fused Desposition Modeling) 3D printer to have several separated colors directly in your 3D print. Or you can 3D print directly in multicolor, directly in the 3D printer, with pretty much as many colors options as you have in a traditional 2D printer. Today we explain how multicolor 3D printing works, and what you can do with it.

What is multicolor 3D printing?

We call multicolor 3D printing or “full color” 3D printing a process in which the colors are directly applied in the object while it is 3D printed, and that allows color combinations, just like a paper 2D printer allows color combinations, with several colored inks.

There are three main 3D printing technologies that allow to 3D print in multicolor: Binder Jetting, Selective Deposition Lamination and a variation of Polyjet technology. The one that is most used (and used by Sculpteo for our multicolor 3D printing) is Binder Jetting. This is the technology we are going to focus on and explain in this article.

How does the Binder Jetting multicolor 3D printing technology work?

The Colorjet 3D printing technology

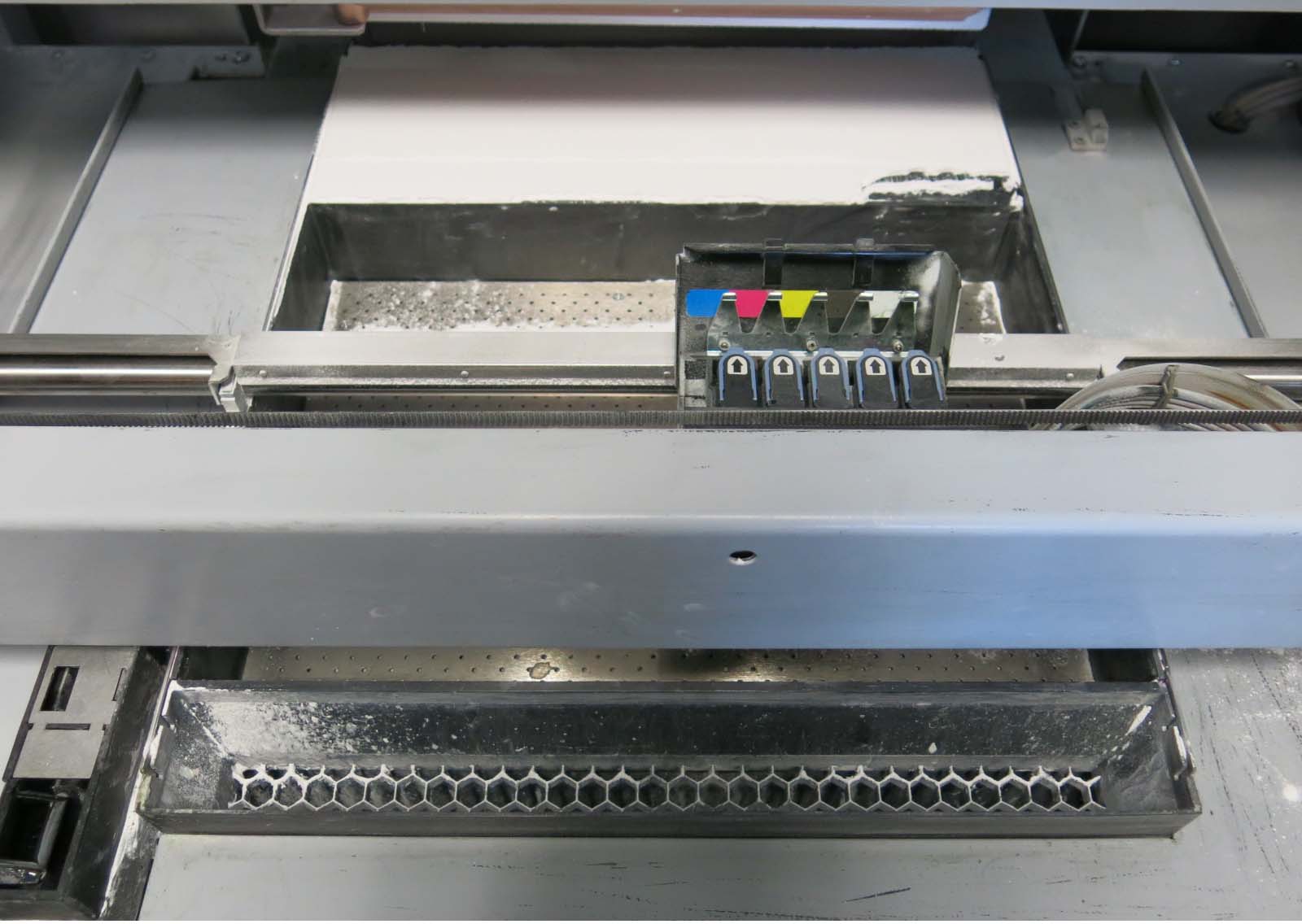

Here at Sculpteo, we use a ZCorp 3D printer for our composite multicolor prints. The process of our Colorjet 3D printing technology goes as follows:

- 3D Model transferred to the 3D printer

Before the actual printing process begins, you need to create a 3D model using a program dedicated to 3D modeling. You will need to export not one but two files from the 3D modeling program, one will include the physical shape and size of your object, the other needs to include the texture and color details. Those two files can then be uploaded to our website in one .zip file.

Your 3D model and its texture details are then sent to our 3D printers and arranged for the next available batch. For composite multicolor prints, the model will be placed in the batch meant for a ZPrinter 650s by 3D Systems.

- The Object is getting 3D printed

During this step, your object is actually being printed layer by layer. A rolling batch will create a uniform layer of a sandstone-like powder. From there on, two printing heads pass over the batch, coloring and adhering the object at the same time. The batch of powder then makes another pass, until the object is completed.

- The Object is removed from the batch

During this step, the objects are manually removed from the batch. The excess powder from the print is kept for a future print in order to prevent material waste.

- Cleaning and gluing

The process is nearly finished. During this step, the excess powder that could not be removed by hand will be removed with pressurized air. The object is then put in a cyanoacrylate bath, which results in further solidifying the object and also enhances the colors even more.

- Varnishing

During the last step, your object will be given an anti-UV varnish to protect it from extensive light exposure. If you choose a different varnishing option for your object, it would also be applied during this final stage as well.

What colors can multicolor 3D printing create?

The combination of colored glues can create a very wide range of colors: up to 390 000 different colors, with the machines we use!

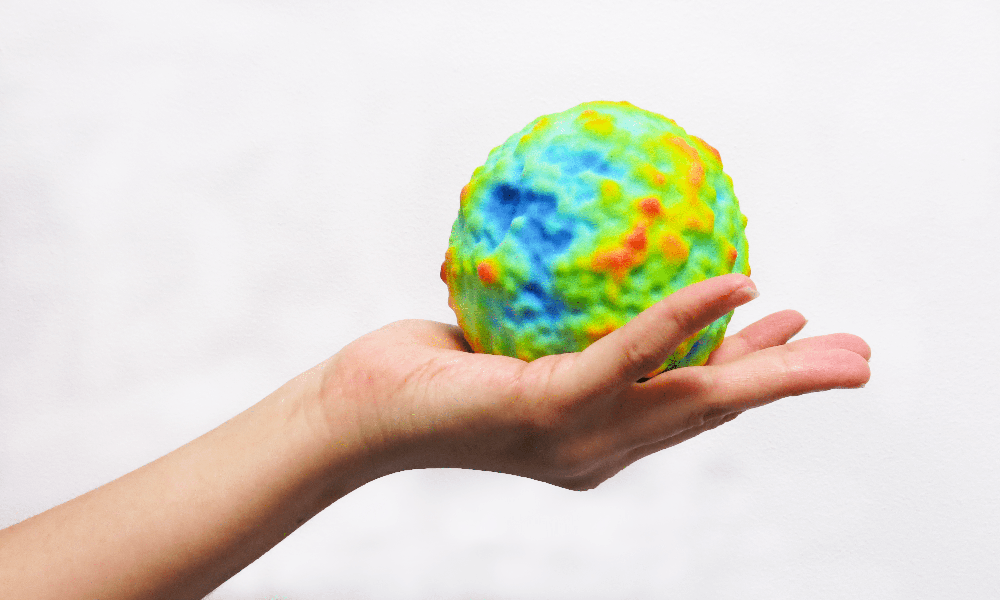

This is a thermic map of the universe, that we 3D printed. You can read the article about this here.

Which material is used for multicolor 3D printing?

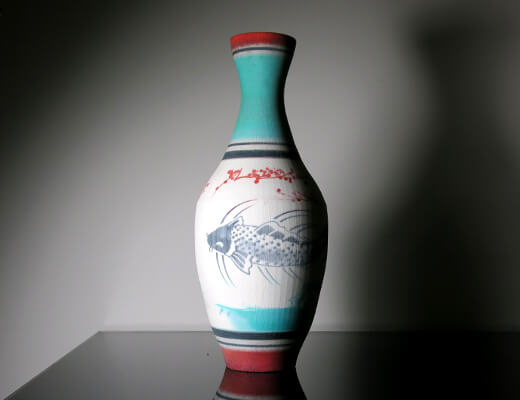

The 3D printing material used is a composite material that resembles sandstone. To the touch, the prints have a gritty, rugous texture, and are relatively porous.

What finish can be applied to a multicolor 3D print?

At Sculpteo, we offer three finishes: raw (no additional finish after the gluing), matte varnish or glossy varnished. The varnish we apply is anti-UV, and protects the object from extensive light exposure.

Which 3D printer is used for multicolor 3D printing?

The multicolor 3D printers we use are ZCorp 650 machine and 3D Systems’ ProJet 660Pro. There are other professional full-color 3D printers, such as 3D Systems’ ProJet 4500, or the MCor IRIS.

For a full guide to professional 3D printers, click here.

What type of 3D file needs to be used for a multicolor 3D print?

For multicolor 3D prints, we recommend using a .OBJ or .WRL 3D file format for the 3D design. This 3D file comes with a texture file, which is an image, that will add the colors to the 3D object. The texture file can be in the following formats: jpg, gif, png, bmp, tiff, xpm, tga, ico, wmf, pcx, [or] xbm.

The two files are then compressed together into a .zip. You upload this .zip file onto our online 3D printing platform. It’s important to keep the weight of the file low in order for it not to be rejected.

An interesting question is: which resolution is best for the texture file? In a previous article, our team made tests with various texture file resolutions, to check when a higher resolution produces a better quality of the print, and when it’s not necessary (and makes the file too heavy for not much result). They came up with the following conclusions:

- For any prints with a height smaller or equal to 15 cm use a 1000 x 1000 pixels texture resolution

- For any prints with a height included between 15cm and 20cm use a 2000 x 2000 pixels texture resolution

- For any prints with a height included between 20cm and 30cm use a 4000 x 4000 pixels texture resolution

- For any prints with a height included between 30cm and 38cm use a 8000 x 8000 pixels texture resolution

To read the full experiment that led to this conclusion about the resolution of your texture file for multicolor 3D printing, click here. This article will also tell you more about the compression of your file and the size it needs to be.

To read more about the file requirements for multicolor 3D prints, click here.

To learn more about what a texture file is, you can go to our g3D printing glossary.

What are the design guidelines for a multicolor 3D print?

The size of your 3D printed object must be below 254 x 381 x 203 mm, and above the minimum size of 2 x 2 x 2 mm. The minimum wall thickness is 2mm, and 3mm if the part is isolated (self-supported). Two walls need to be spaced by at least 0.9 mm. Details can’t be smaller than 0.4 mm.

For all design guidelines for our multicolor 3D prints, check out our multicolor 3D printing material page.

What resolution can be expected of a multicolor 3D print?

The layer thickness for our multicolor 3D prints is 100μ. Because of the limitations of multicolor 3D printers, there may be some imprecisions in the print: we ensure a maximum precision of ± 0.5mm for pieces 99mm or smaller and a global precision of ± 0.5% for pieces 100mm or larger.

Read everything about the 3D printing resolution for multicolor parts here.

What are the technical properties of a multicolor 3D print?

Objects 3D printed in multicolor have a porous surface, which means they shouldn’t be exposed to water, at the risk of the colors running. They can resist temperatures up to 60°C. Submitted to higher temperatures, they will probably be damaged. They are quite fragile (comparable to porcelain) and should be handled with caution.

For more precise technical specifications, check out our multicolor 3D printing material page.

What are the advantages and drawbacks of the “full color” technology?

Advantages:

The full color 3D printing technology is an extremely advantageous way to create multicolor objects: fast, inexpensive, and simple (especially when using an online 3D printing service). It builds very aesthetic objects, and gives the inventor a lot of creative freedom: you can imagine colors, tints, changes in the shades that would probably very difficult to achieve with other coloring techniques, and they arrive directly on your object, ordered by the 3D file and texture file you’ve created. It is also faster and sometimes more accurate than hand painting, and allows creators with few experience in hand modeling and hand coloring to develop their 3D modeling skills instead, and let the machine do the material work.

Drawbacks:

The fragility that we’ve mentioned is quite a large drawback, and means multicolor 3D printed objects are, for now, mostly destined to be ornamental. We’ve also mentioned its lower dimensional accuracy (compared to SLS or SLA). It’s also difficult, using Binder Jetting, to achieve color consistency: from one print to the other, with the same 3D and texture files, the colors might change slightly. This means it is wiser, when you want to 3D print 10 times the same object, to do one job of 10 objects than to do 10 jobs of 1 object.

What are the applications of an object 3D printed in multicolor?

In conclusion, multicolor 3D printing is a great way to create artistic, ornamental objects, such as figurines (often realized with a 3D scan), avatars, reproductions of historical objects or buildings or famous characters. It also allows to create, at a low cost and with a much-simplified process (coloring is removed from the steps) proof of concepts and prototypes of aspects. For those two last examples, it is important to remember to handle and transport with caution.

I hope this article inspired you to create a multicolor object, or to look into our other 3D printing materials. If you wish to try out our online 3D printing service, you can upload a file now.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook