3D printing black plastic: Nylon PA11 replaced by HP Multi Jet Fusion PA12

Posted By Lucie Gaget on Sep 26, 2017 | 0 comments

We are changing our offer to give you the opportunity to create 3D printed objects with high-quality material. The 3D printing black plastic available on our online 3D printing service will not be Nylon PA11 anymore, starting from september 30, 2017. HP Multi Jet Fusion PA12, which was a beta material until now, will be the only black plastic that we’ll be offering. We are going to explain you why, and tell you more about this new 3D printing black plastic.

3D printing materials available at Sculpteo are changing

Nylon PA11 will not be available anymore on our 3D printing service. If you want to 3D print black plastic, you can now use Multi Jet Fusion PA12 (HP Black Plastic). This 3D printing material was already available at Sculpteo, but it was a beta material. Now, our newest black plastic material, Multi Jet Fusion PA12, is available for everybody!

Why we chose to replace Nylon PA11 by HP Multi Jet Fusion PA12?

At Sculpteo, we are paying close attention to your needs and we want to offer you the best materials available on the market. That’s precisely why we chose to replace our black plastic material Nylon PA11 by HP Multi Jet Fusion PA12. This is a high quality material. For example, it is ideal if you want to create resistant objects or complex shapes.

Beta users had an exclusive access to this new material on Sculpteo. As they were enjoying HP Multi Jet Fusion PA12, and created good parts, we decided that all the users should have access to it. This is not a beta material anymore. We are really happy to work with HP in order to make 3D printing even more qualitative. That’s why HP Multi Jet Fusion PA12 is now our only 3D printing black plastic!

Multi Jet Fusion PA12, an efficient black plastic for 3D printing

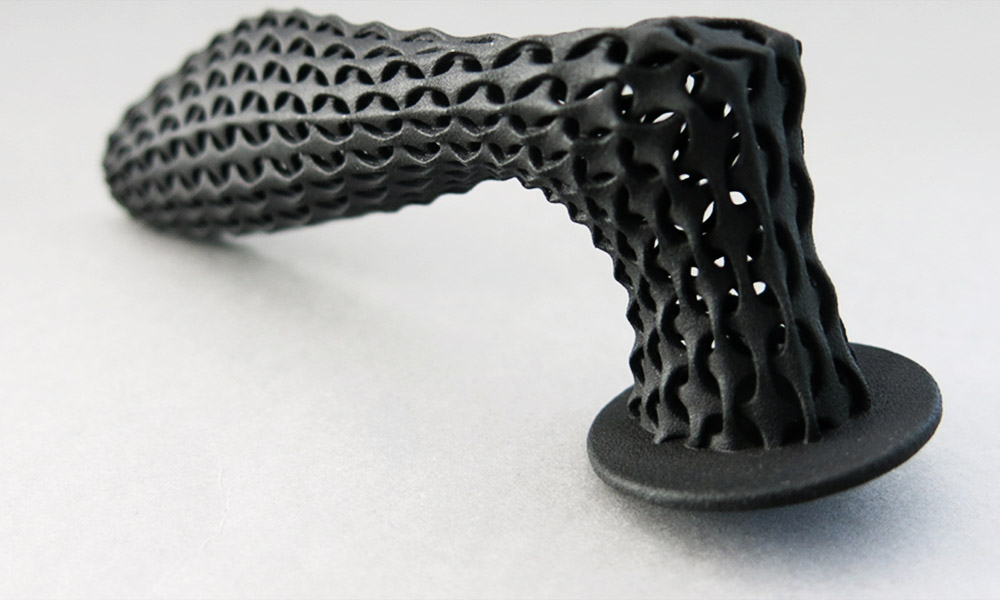

Multi Jet Fusion PA12 is created from a fine polyamide powder and is characterized by a great elasticity and a high impact resistance. The objects 3D printed with this black plastic are resistant to chemicals, scratches and abrasion. Multi Jet Fusion PA12 is light stabilized and is stable to every weather. It is also a good material as it allows a high precision for the 3D printing of your design!

To print this material, we use a process called Multi Jet Fusion, invented by HP, which creates parts using a multi-agent printing process. A printer head deposits selectively some drops of fusing agent and detailing agent on a powder bed, then an infrared light heats these parts to fuse the material.

If you want more information, read more about our Multi Jet Fusion PA12 material on our website.

Create a final product with HP Multi Jet Fusion PA12

You can create prototypes using this new black material for 3D printing. But it is also perfect to do fully functional plastic parts, especially for applications in the automotive sector, electronics, education or even in the medical industry. Multi Jet Fusion PA12 has good mechanical properties, thus it is often used to substitute injection molding plastics.

There is no particular finishing available for Multi Jet Fusion PA12. Nevertheless, this black plastic material is relatively smooth after coming out of the printer, thus it doesn’t need a special finish.

Feel free to upload your 3D model on our 3D printing service and enjoy the efficiency of the HP Multi Jet Fusion PA12. And if you want to have a better idea of the advantages of the different plastics, check our blogspot on the differences between polyamides PA11, PA12 and HP Multi Jet Fusion PA12

You still have questions about this new black plastic? Maybe this blogpost answering to 7 questions about Multi Jet Fusion PA12 will help you. You can also take a look at the other 3D printing materials available on our website!

If you need more precisions about this material, contact us!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook