3D Printing Material: Multi Jet Fusion PA12 in 7 Questions

Posted By Hilmiyati Kusnadi on Aug 9, 2017 | 0 comments

Since we launched our new material Multi Jet Fusion PA12, we can proudly say that it generated a lot of enthusiasm, especially from those who were waiting to experience HP’s Multi Jet Fusion technology. For now, there’s only one material available: Multi Jet Fusion PA12, allowing you to 3D print black plastic parts of high quality, but more 3D printing materials should be launched soon! Today, we will tell you more about this 3D printing material in 7 questions!

What is Multi Jet Fusion PA12?

After releasing this material as a part of our BETA program, our Multi Jet Fusion PA12 is now available on our 3D printing service. The objects 3D printed using this new material, made from a fine polyamide powder, have a good elasticity and high impact resistance. This new material allows you to get great details thanks to the detailing agent that is used during the printing process. Thus, you can create complex designs.

Moreover, Multi Jet Fusion PA12 is water-resistant, but not waterproof. It is adaptable to every weather, light stabilized and resistant to chemicals.

Which 3D printing technology is being used for Multi Jet Fusion PA12 parts?

To 3D print your parts in Multi Jet Fusion PA12, we use HP’s newest technology: Multi Jet Fusion.

How does the Multi Jet Fusion Technology work?

The Multi Jet Fusion technology is a method invented and developed by HP. It is a powder-based technology which creates parts using a multi-agent printing process.

The 3D printing process begins when a fusing agent is deposited on a powder bed, then followed by drops of a detailing agent to improve the part’s resolution (thus creating fine details and smooth surface). The area is then exposed to an infrared light to heat these agents and the material in order to create the objects.

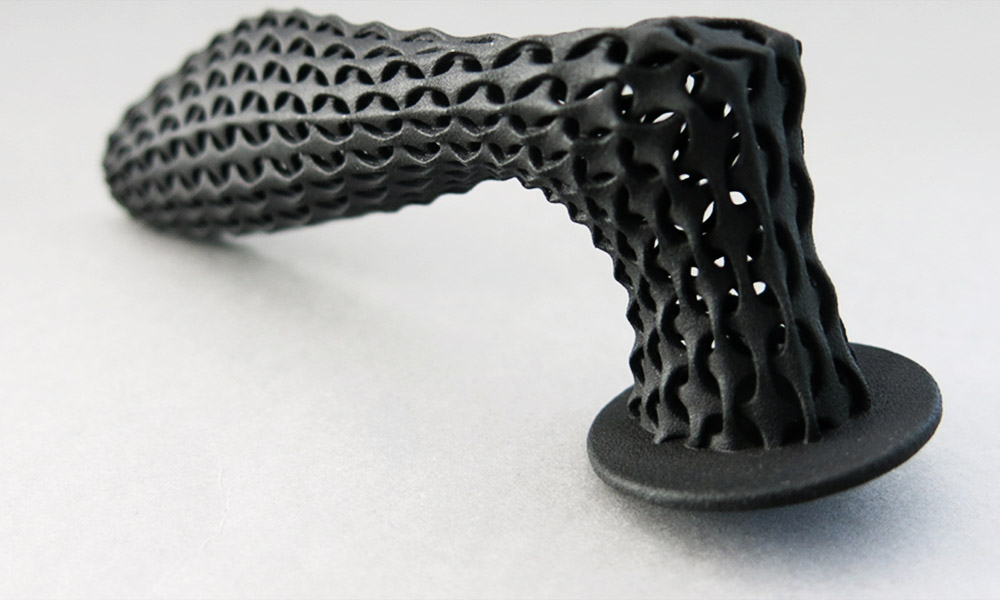

What does Multi Jet Fusion PA12 look like?

Our Multi Jet Fusion PA12 creates black plastic 3D printed parts. Unpolished is the only finishing option available on our online 3D printing service. However, the surface is exceptionally smooth after coming out of the printer.

For what kind of 3D printed parts is Multi Jet Fusion PA12 a good choice?

Marked by an excellent strength and high impact resistance, the objects 3D printed with Multi Jet Fusion PA12 can be used for mechanical purposes such as prototypes or finished products like geared systems.

Our Multi Jet Fusion PA12 is also perfect for applications in the automotive sector, electronics, education or even in the medical industry.

What are the size limitations and design guidelines to successfully 3D print parts with Multi Jet Fusion PA12?

In order to 3D print your parts with our Multi Jet Fusion PA12, the maximum size to build an object is 274 x 370 x 349 mm (10.8 x 14.6 x 13.7 in). Designing several objects and including them in an assembly mechanism can be the best solution if you need to build an object which is larger than the maximum size. Multi Jet Fusion’s strength can be seen in its resistance to assembly and disassembly. However, you need to have a distance of at least 0.5 mm between different parts of the objects.

Moreover, the HP Multi Jet Fusion 3D 4200 printer allows to print with a layer thickness of 80 µm (0.08 mm). The technical properties can vary depending on the thickness of the model. If you set a minimum wall thickness of 0.6 mm, your 3D printed parts become more flexible. On the other hand, a 2 mm wall thickness can make your object become fully rigid.

Learn more about the design guidelines in the page dedicated to Multi Jet Fusion PA12.

You can also find some of our best tips about wall thickness to help you design your 3D model.

How should I prepare my file for 3D printing with Multi Jet Fusion PA12?

Before using our online 3D printing service, you need to create a 3D model using a CAD software. The good thing using Sculpteo’s online 3D printing service is that we also offer you online 3D printing software tools. These tools allow you to edit, optimize, repair and review your model without having to go back to your modeling software. To be able to use our 3D printing software tools, simply upload your 3D file to our platform.

For those who are tempted to experience 3D printing with this amazing black plastic material, benefit from 10% off your orders on Multi Jet Fusion PA12. Use code: MULTIJET and upload your 3D file here.

So, are you ready to 3D print your parts with our Multi Jet Fusion PA12? Upload your file here!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook