3D printing in space: The next revolution?

Posted By Lucie Gaget on Nov 29, 2017 | 0 comments

3D printing is beneficial for aerospace applications in many aspects. Indeed, it could become a significant asset for space travels in the future. On earth, research is already evolving quite fast. Step by step, researchers are also finding different applications for this cutting-edge technology in space. 3D printed parts are sent to space, but some technologies, able to 3D print directly in microgravity or in the vacuum of space, are also developed. Additive manufacturing in space is a real challenge. It requires new technologies and resistant materials.

This blog post will show us what it can do in space today. We’ll see the different challenges of 3D printing in space regarding the conditions, the machines, and the materials. You’ll learn about the last experiments and the most promising technologies developed in this sector. Finally, we’ll give you a sneak peek of the future of 3D printing in space, with some impressive projects that could emerge in the upcoming years.

The challenges of 3D printing in space

Why is it attractive to 3D print in space?

First of all, why should we use additive manufacturing in space? Just for research and experimentation? Additive manufacturing is exciting when it comes to the aerospace field. 3D printing directly in space could be a fantastic opportunity.

There are two different axes of applications and two benefits of this technology: 3D printing inside and 3D printing outside the station. Inside of the station, it will help the astronauts significantly in their daily life in orbits during space explorations. For example, when something is broken, and they need to replace a part, it can be long and expensive to send them what they need. They could simply 3D print it. It is the same thing if a tool is missing. It would be much easier and time-saving if they could 3D print their screwdriver when needed!

The additive technology outside of the station could also simplify logistics. A 3D printer working in orbit would allow for the creation of satellite structures. These machines could be integrated inside nanosatellites. Pascal Martinelli, professor at the IUT of Cachan and working on additive manufacturing and nanosatellites projects, explained, “Additive manufacturing will help the crew during their space missions. Big structures are quite difficult to stock on board and to put in orbit. That’s why 3D printing is a good solution. Nanosatellites could allow 3D print structures directly in space. ”

Nanosatellites, as you can guess by their names, are smaller than traditional satellites. Thanks to their cubic shape, they don’t take much space inside a rocket. They offer many possibilities, one of which is to create 3D printed objects in space.

It is one thing to work with a 3D printer inside a spatial station, but doing additive manufacturing outside of the station is a new challenge that could change the working methods of the astronauts.

Why is it such a challenge to 3D print in orbit?

Additive manufacturing in space can’t use the same process as additive manufacturing on earth. It is just impossible to use a traditional 3D printer with zero gravity. The machine has to work in a different environment. The first thing is, when 3D printing in space, the part has no support, and it’s impossible to put down the part on the build tray. The machine has to shape the part literally in the vacuum of space.

The printing technology in orbit is an entirely different experience. The printing material and the machine used to have to be more resistant, with other characteristics to last a long time. A 3D printed part, whatever its use and even if it is published on earth, must be resistant to evolve in space conditions. Thus, the printing material matters.

Current experiments regarding off-Earth manufacturing

Different experiments are developed thanks to additive manufacturing. Here, we’ll focus on two specific and promising projects, aiming to create 3D printers able to 3D print directly in the vacuum of space. We’ll talk about the SpiderSat and the Archinaut.

Spidersat: What is it, how was it built, and how does it work?

Spidersat is a nanosatellite developed by the students of the University of Paris Sud (IUT of Cachan) based on an idea from the CNES. Professor Pascal Martinelli has already worked on a project with his students: the Eyesat. If you want more information on this satellite, you can check our previous blogpost about Pascal Martinelli’s work on the Eyesat. These nanosatellites are part of the JANUS project, a program promoting spatial technology and allowing students of more than ten french schools to work on nanosatellites.

Spidersat is a nanosatellite conceived by Pascal Martinelli and his students. He has been working on it for three years now. In the beginning, the aim was to create a functional prototype, but it would take a lot of time. For the moment, it is more practical to work on 3D printers that are functional in space, working with the FDM (Fused Deposition Modeling) technology. As you can imagine, dealing with powder to do some Selective Laser Sintering without gravity could quickly become an absolute nightmare!

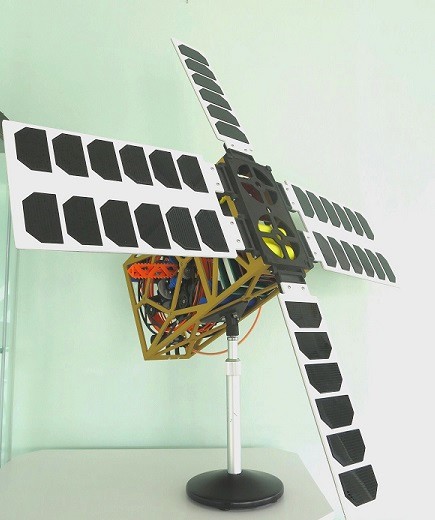

What you can see in the picture below is the prototype built by Pascal Martinelli and his students:

This prototype is impressive and shows all the mechanical parts of the nanosatellite. It has been created thanks to 3D printing with our online 3D printing service. All the parts, except the solar panels and the aluminum structure, are created thanks to additive manufacturing technology.

Pascal Martinelli stated, “I’ve been working with 3D printing since 1998. Additive manufacturing is the best way to give life to ideas. You can quickly transform a CAD model into a physical object at a lower cost.” Regarding the CAD software used for this project, Pascal Martinelli said that Solid Edge was appropriate, quite similar to Solidworks, but more focused on a mechanical aspect.

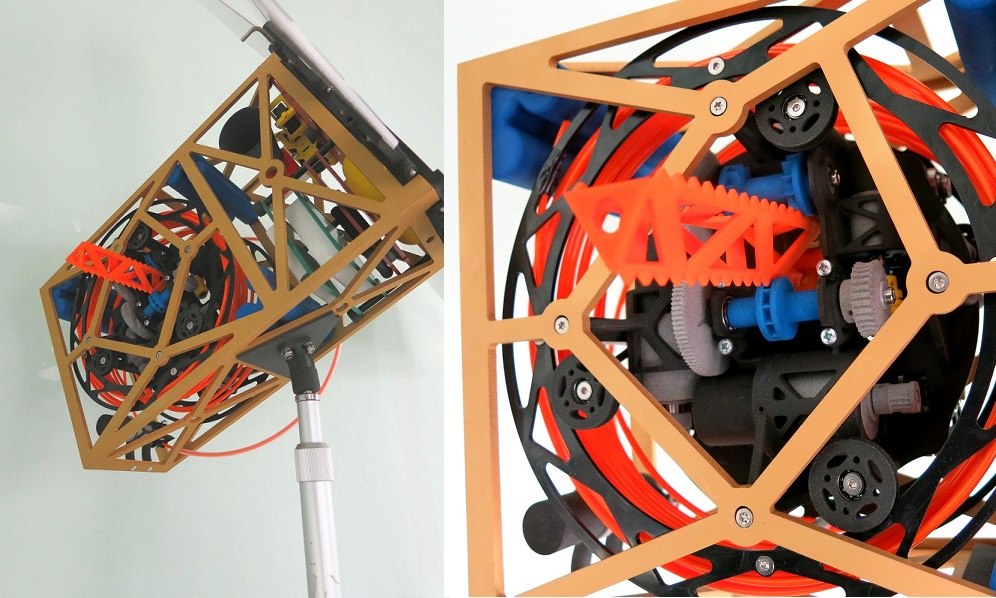

In the picture below, you can see the triangular profile created with FDM technology. It is a piece of the final part printed by SpideSat. The tooth will be linked to a cogwheel. They will make the part go out of the machine. It will create new teeth gradually, which are here to pull out the part.

On earth, there is gravity. The part can lay on a build tray that will progressively go down during the printing process. Here’s one major problem: How can the printing process start in orbit if the feature needs a tooth to be pulled out? Unfortunately, it can’t. That’s why, for the moment, the very beginning of the structure has to be printed on earth. Then the rest of the process works perfectly well in space.

“SpiderSat could be able to manufacture a continuous part of 20 meters long – but we could be able to create longer parts in the future. It just depends on the reservoir!” states Pascal Martinelli.

The construction of a functional Spidersat could come soon. We’ll keep in touch with the IUT of Cachan and show you the future demonstration of this project in a new blog post.

Made in space and the Archinaut 3D printer

Made in space is a California-based company that has already worked with NASA to create a 3D printer inside the International Space Station (ISS).

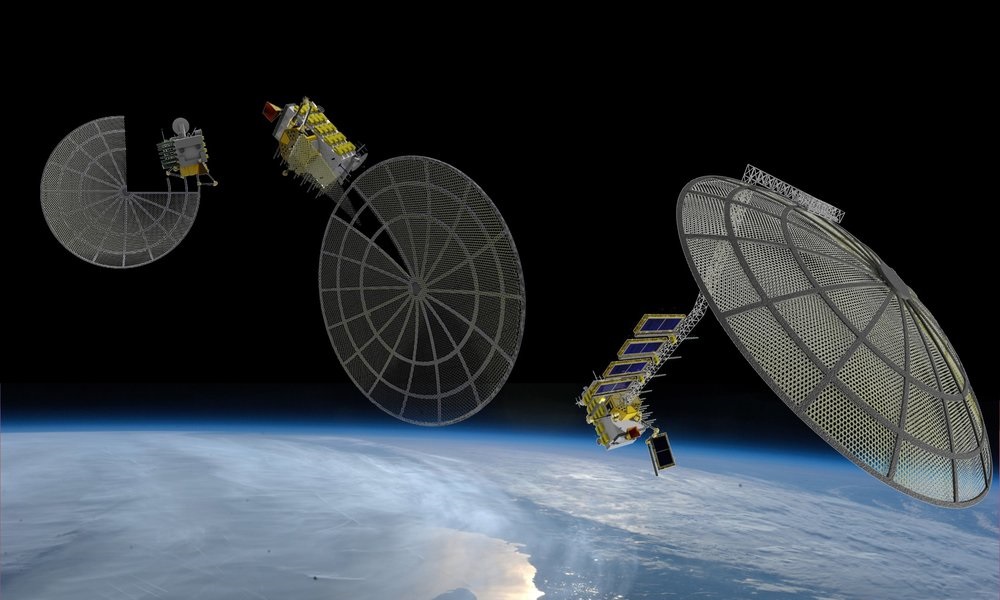

Made in space is working on a new 3D printer, Archinaut, that can 3D print an entire satellite outside the station. It will be launched in 2018. With a bit of patience, we will be able to see the result of their experiment. This impressive machine is composed of a 3D printer and robotic arms to assemble the parts of the structure.

Moreover, the advantage of this machine is that it is dedicated to large-scale manufacturing. It could create parts that are not even transportable! This machine’s gravity is totally out of the equation, and new satellites could be built directly in space. The Archinaut system could even repair existing satellites.

This ambitious project is a natural step forward for additive manufacturing technology.

You can watch its presentation video below:

What are the 3D printing materials that we can use in space?

Creating large-scale structures thanks to plastic

Is it possible to use 3D-printed plastic in space? Actually, yes, but you can’t use all of them.

For example, PLA and PVA are incompatible with additive manufacturing in space because those kinds of plastic are not resistant enough to space conditions. To be printed in space and create a tool or a part of the structure of a satellite, the printing material has to be quite resistant to low and high temperatures.

For their experiment with Archinaut, the team of Made in Space is planning to use a new kind of plastic. This unique material is made of polyetherimide/polycarbonate or PEI/PC. It is several times stronger than the traditional plastic printed inside the International Space Station.

Polyetherimide and polycarbonate are two different thermoplastics primarily used in engineering. These are very resistant plastics and easy to model, which is particularly good for 3D printing to create the shapes you need with great precision. Also, these materials have great thermostability and resilience, perfect for experiencing space conditions.

“In a vacuum, [PEI/PC] is not going to [emit particles], it’s resistant to the UV environment, it’s resistant to atomic oxygen so that it can perform actual uses in space,” says Matt Napoli, vice president of Made In Space.

3D printed metal in space: What can we expect?

- Metal 3D printing without gravity

Thinking about a resistant 3D printing material without thinking of metal is impossible. Indeed, metal is a great solution. Researchers at the German Federal Institute for Materials Research and Testing and TU Clausthal are working on a project to 3D print metal parts without gravity. This project is called “Powder-based additive manufacturing in zero gravity.”

As it’s not possible to 3D print the same way on earth and in space, researchers had to develop a brand new technology. How is it possible to the 3D print metal without gravity?

These researchers are using a 3D printer based on binder jetting technology. And instead of gravity, a powerful air jet is used to stabilize the part. This process has been tested in the ZERO-G Airbus A310 from Novespace. There are many parameters to consider, such as preventing the powder from escaping the facility. The layer application process must take place in a hermetic enclosure.

- The AMAZE project to print 3D metal parts

AMAZE project (AMAZE for Additive Manufacturing Aiming Towards Zero Waste & Efficient Production of High-Tech Metal Products) is also working on a project to 3D print metal parts. Their will is to put this metal 3D printer in the ISS. It would be the first time a 3D-printed metal object could be created inside the station, in space.

This project is unveiled by the ESA (European Space Agency). It will allow the creation of complex 3D printed parts that couldn’t have been created with traditional manufacturing. The will of the ESA is to be able, in the future, to 3D print significant parts, like an entire satellite in one part. Thanks to this 3D printing process, no need to assemble the parts. It is perfect for reducing the costs, and it can be helpful for little parts for engines, but also significant parts. For example, they printed a 2-meter-long part for wings.

One of the main advantages of metal is the possibility of printing parts that are extremely resistant to heat. At least parts can resist temperatures up to 1 000 degrees. For example, parts in tungsten were conceived. It is a highly heat-resistant metal. Details of the ITER Tokamak, a nuclear fusion reactor, were developed with this impressive metal. Also, the ESA mentions that 3D printing metal is an efficient solution to reduce metal wastes: you only have to get the weight of metal that you need to 3D print your object! In the future, they aim to be able to recycle 3D printing material. It would be easier to use materials like tungsten, which is extremely expensive but could allow them to initiate impressive 3D projects in orbit.

We can already see how incredible and helpful metal 3D printing can be on earth or during space explorations. This technology will become more mature in the future of 3D printing and will continue to surprise us. For the moment, researchers are still looking to solve some problems to get perfect industrial parts: the major problem is the porous aspect of the final parts due to air bubbles.

There are still some imperfections, but they will indeed be overcome soon!

The ISS and 3D printing: The Zero-G Experiment

Some experiments have already occurred inside the ISS regarding additive manufacturing technology. Little by little, 3D printing has become a must-have element inside the station during space missions. Why is this technology so helpful in space?

In 2014, NASA did what they called the Zero-G experiment with Made in Space. The 3D printer they made for the International Space Station allows astronauts to 3D print objects themselves. The significant difference between this printer and technologies such as Spidersat or Archinaut is that this 3D printer doesn’t have to experiment with extreme conditions like pressure, vacuum, or temperature changes in space.

This project emerged because of a problem: astronauts needed to find a way to get their tools in orbit without transporting them. Moreover, sending them material is a pretty long and expensive process. It is a problem when they have to fix a single element or need a specific tool they could ideally create by themselves.

But it could also be a way to get medical devices on board when someone needs them. It simplifies quite a lot of situations. Julielynn Wong founded 3D4MD, a company offering medical devices thanks to new technologies, in an area where they don’t have any access to it. She tried to use the 3D printer of Made in Space, which was quite successful. It is good news for the astronauts. They won’t have to wait to get health care on board.

This experiment aimed to see the environments and microgravity of the additive manufacturing process. It was also to show that astronauts could print room wrenches, screwdrivers, natural functional satellites, and life support systems.

To go further: What is the future of 3D printing in space?

NASA will undoubtedly use 3D printing more frequently in the future for all of the reasons we saw previously in this article. But other incredible projects might be feasible in a bit of time.

Let’s see quickly the most exciting projects linked to 3D printing that will be developed in space in the upcoming years:

- The Refabricator is a project which will be experimented with in 2018. This machine can print and recycle the printing material. It will allow to recycling of plastic and waste. It will significantly help reduce the costs of space travel and the impact of those travels on the space environment.

- Creating a 3D printed base on the moon is a project of the ESA. The aim is to build a little city in regolith on the moon, thanks to 3D printing. This project will eventually start in 15 years. Humans will be able to walk and 3D print on the moon.

- Lunar Quattro is a project developed by Audi with additive manufacturing. It is a robotized vehicle that will be sent to the moon to take 360° pictures.

- Companies like SpaceX already test 3D-printed rocket engines, showing all the additive manufacturing capacities. Soon, it could be even more familiar to 3D print a machine, even for a rocket! It could be possible to create 3D or partially 3D printed rockets.

If you want to know more about space and 3D printing, you can check one of our previous blog post about how 3D printing technology will change space travel.

The next step for space-based 3D printing is to build massive structures in space, thanks to new technologies, and apply what was already tested in parabolic flight in orbit.

Many promising experiments will be done in the upcoming years, and we will keep you informed of the results. To get all the 3D printing news directly, don’t forget to subscribe to our weekly newsletter.

Photo credit: http://madeinspace.us/

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook