Discover our team’s favorite 3D printing projects!

Posted By Lucie Gaget on Dec 6, 2017 | 0 comments

As an online 3D printing service, we see a lot of different 3D printing projects and we keep an eye open, to see all the innovations appearing in this sector. There are amazing projects and, some of them can stay in your mind for a long time because you find it revolutionary, innovative, or just because it makes you laugh.

At Sculpteo, we asked to some of our team members to tell us about their favorite 3D printing project. All the members chose very different projects. It can be a poetic one, a useful one, it can be linked to their passion or their convictions. Sometimes, these 3D printing projects are even more personal, as some collaborators decided to develop their own projects with this amazing technology. There is a contrast between all the projects that have been chosen by the team, and it shows how diverse the applications of additive manufacturing can be.

Here are the favorite 3D printed projects of our team, here, at Sculpteo!

Our team’s favorite 3D printing projects

This list of our favorite projects reveals that behind the cold aspect of a manufacturing process, 3D printing keeps a creative and poetic side. Indeed, 3D printing allows to create useful things as well as more fun projects. It is always a way to go further with innovation, whether to be useful or not. This blogpost will show you all the possibilities offered by a technology such as additive manufacturing.

-

Marine Coré-Baillais, Deputy CEO, and the 3D printed paper airplane gun.

Marine chose the 3D printed paper airplane gun as her favorite project. This amazing project was created by Dieter Michael Krone, a german man, who visibly keeps following his childhood dream. He created a first model of this curious weapon in 2014, but did some updates recently to make it even more efficient.

Take a look at the video below to understand this fantastic project and see how this PFM A5 v2.0 works:

Why does Marine love this project? She explains: “This project symbolizes for me one of my favorite things: technical mastery at the service of a dream. The perfect combination of poetry and mechanics. Because M. Krone is not a conceptual contemporary artist, it makes me think his project is even more beautiful.”

This 3D printed gun is able to pull 120 paper airplanes by minute, it is quite a performance, and it is possible thanks to an ingenious mechanism that folds the paper and throws it in the air.

“We must be able to keep time to do unnecessary things.” concludes Marine.

-

Alexandre d’Orsetti, industrial designer, and the Solar Sinter Project

Instead of Selective Laser Sintering, could it be possible to use Solar Sintering? That is the point of this project created by Markus Kayser, and chosen by Alexandre.

“Contrary to a lot of additive manufacturing projects, this project is experimental and artistic. It has no industrial significance. The parts don’t have an incredible technicity. Nevertheless, I find this project interesting and poetic” explains Alexandre.

The Solar Sinter Project is a machine developing a new additive manufacturing process, only using sand and sun. When silica sand is heated to its melting point and then cooled down, it solidifies as glass. The idea is to create a real object only using a natural technology.

“First of all, this is a local project, it is very contextual. The artist uses all the elements available in this environment: silica sand and sun. Moreover, we clearly see the transformation of the material, the fusion of the sand becoming glass with the beam of light. This project is a didactic method to understand laser sintering. Here, the laser is the sun, and the powder is the Sahara’s sand.

There is a startling contrast between the technological aspect of the machine, nearly spatial, and the rustic dimension of the desert. The fact that this process can create a real part is a bit of magic, alchemy. I like the evocative side of this project, it invites us to think about scenarios of auto-production, micro-architectures and some kind of technological nomadism”

-

Ludovic Coues, software engineer, and the 3D printed Totem

This 3D printed totem is available on thingiverse and will help you to organize your messy desk!

“A lot of designs are available on thingiverse, but this Totem is my favourite. I had a crush on this project, it means a lot to me, especially in the little details. I have the habit to pile stuff up everywhere. My desk is covered with pens, felt pens, cuddly toys, unfinished electronic projects or other objects waiting to be transformed. I hardly stay in an area without a bit of untidiness. But sometimes, a lack of organisation make these spaces impracticable.”

This Totem appears like a real solution to organize his work space, and that’s why Ludovic particularly likes this 3D printing project. It is the answer to a personal need, and it fills the space in an unusual way.

“The possibility of a column where I could tidy all of my gadgets allows me to take up the space in a vertical way, with all of them being easily accessible.

I also like the way it looks, and its name, referring to a theme I love. I like the use of wood in its simple way, coming from an industrial process, and its alliance with plastic, taking complex shapes thanks to 3D printing.” concludes Ludovic.

-

Sylvain Ryser, 3D printing technician, and the 3D printed K9 vision system

This K9 vision system has been partially 3D printed thanks to our online 3D printing service.

This helmet is also a way to show that 3D printing can be useful in diverse sectors. If Sylvain chose this project, it’s because the K9 vision system is closely linked to his passion.

“I love this project, because I personally love dogs. I am actually a volunteer in a Kennel club.

This helmet is really interesting, it allows to search for explosives, or for people. The dog is guided by a loudspeaker and the owner of the dog can see in real time what the dog sees thanks to a camera.” explains Sylvain.

“It’s a cool project and it shows how 3D printing can improve working methods, even with animals. The helmets are small and adapted to the dogs, so it’s not uncomfortable for the dog.”

Indeed, these 3D printed helmets are the proof that additive manufacturing can make working methods evolve. In this precise case, it is a good solution to create helmets adapted to the small morphology of the dogs and it shows, once again, that 3D printing is a good technology to make end-use products.

-

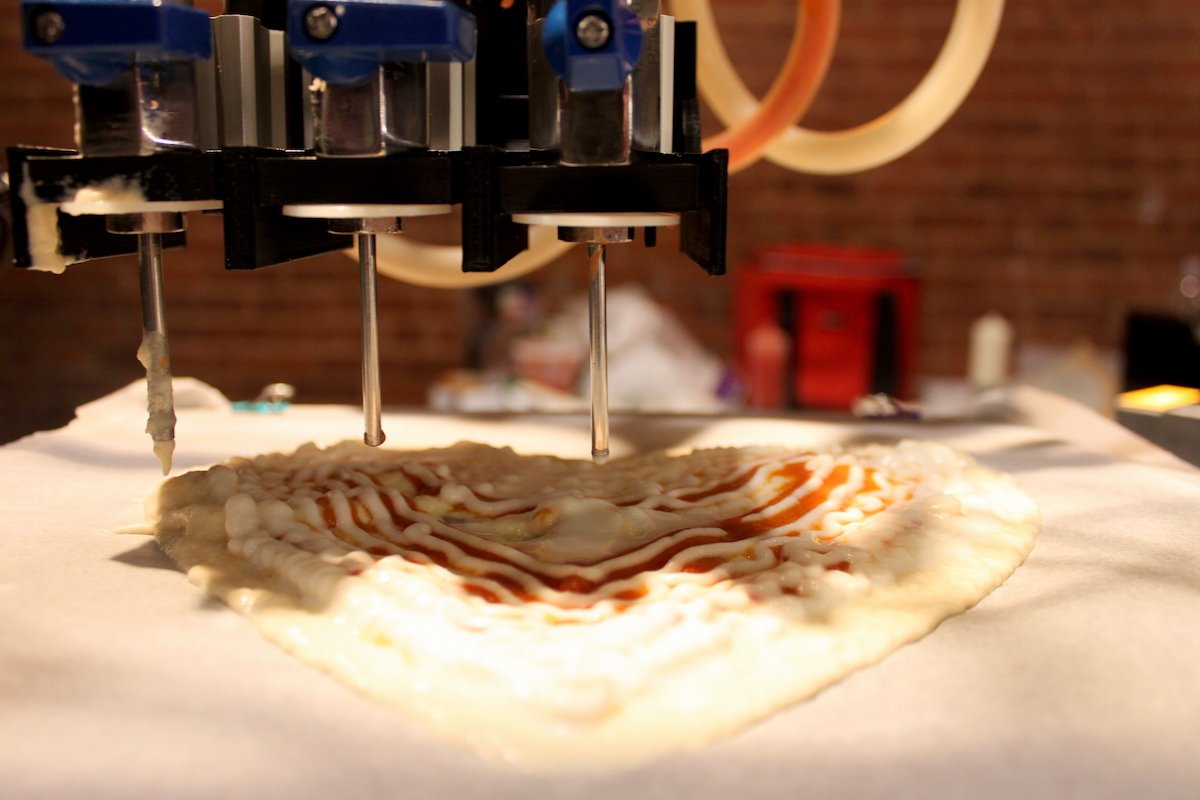

Amandine Richardot, Content Manager, and the pizza 3D printer

The choice of a favourite 3D printing project is often linked to a passion: that’s why Amandine choose to talk about 3D printed pizzas. This technology is way more serious than what you may think!

Amandine explains: “Beehex created the first pizza 3D printer, called Chef 3D. I find it quite fun to imagine that you could use such a machine to get your own pizza in only 6 minutes, with various options in terms of recipes. But this project is way more useful and ambitious than what you could think: they recently raised 1 million $.

It was initially backed by the NASA, and its goal was to find a more efficient way to feed astronauts while they’re on a mission. Using food 3D printing, in that case, could answer one major issue: astronauts could finally eat something tastier than traditional space food. But Beehex also tries to enter the regular consumer market.”

But this technology could be developed to go further with 3D printed food and fit your nutritional needs. Mass-customization could be everywhere, even in your plate.

“Since their goal is to develop food 3D printers (not just pizza ones), it could be very interesting for personalized nutrition: the 3D printer can already make gluten-free pizzas, and could adapt to your nutritional needs, based on data collected from your connected devices, for instance”

The future of 3D printed food appears to be quite promising. If we know how to 3D print a pizza, we could be able to 3D print a lot of different food.

3D printing: The creations of the team!

Sometimes, working in the 3D printing industry can give some ideas to our collaborators. That is the case with two of them today! They decided to talk about their own 3D printing projects.

-

Chris Lau, 3D printing engineer, and his own 3D printer built thanks to… 3D printing!

Chris created his own project: the 3DPrintMi. This is a 3D printer, created with 3D printed parts.

Chris explains the first idea of this project: “3DPrintMi is an open source Reprap 3D printer where it’s primary goal was to incorporate the maximum number of printed parts, thus enabling self replication.”

You can also check out our previous blogpost to learn how it is possible to 3D print a 3D printer.

“3DPrintMi was one of the most challenging yet satisfying DIY projects I have ever worked on. Throughout this project, I have gained an array of skills and knowledge, such as soldering, programming, mechatronics, and of course additive manufacturing.”

“This project never really ended for me because I would constantly implement improvements to the 3DPrintMi but also, I just wanted to keep building more 3D printers!”

We can’t wait to see the next projects that Chris could create thanks to 3D printing.

-

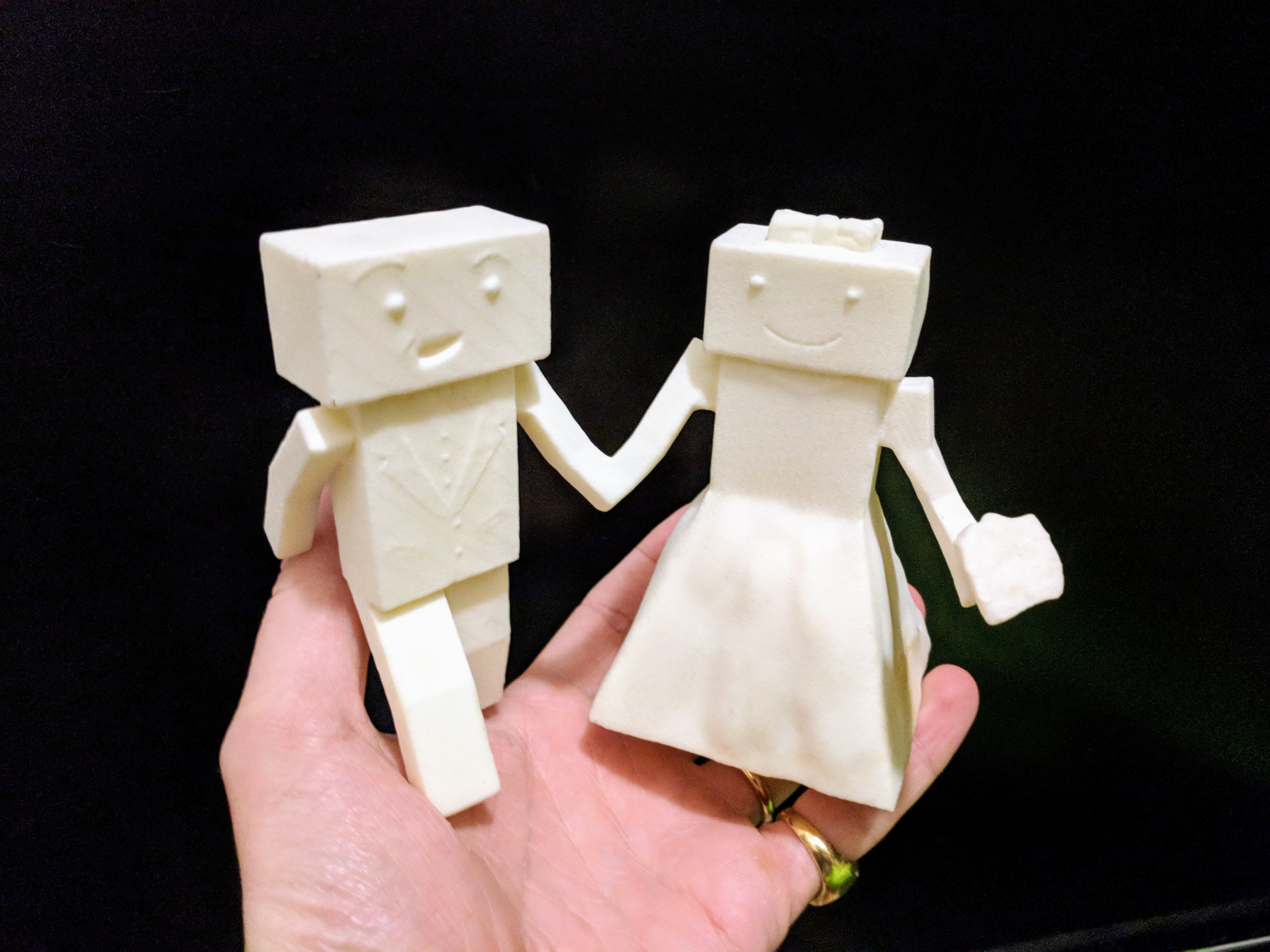

Alex Gryson, UX designer, and his 3D printed figurines for his wedding

Some 3D prints can be very personal, and that is the case here with these figurines created by Alex.

“For our wedding in 2015, the graphical theme for our invitations was a pair of cartoon characters my wife and I designed to represent us.” explains Alex.

“We thought it would be cool to see those characters on the cake. So I created the characters in Blender and cleaned up the mesh in MeshMixer before using Sculpteo’s hollowing tool to save material.”

“This gave us a more personal touch to our special day than a generic (and creepy) pair of porcelain dolls could have!”

To see more of it, check out his website!

And you, what is your favorite 3D printing project? Feel free to leave a comment and share your discovery with us.

If you want to discover more amazing 3D printing projects and news about additive manufacturing, don’t forget to subscribe to our weekly newsletter.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook