3D printing for the energy industry: The best projects

Posted By Lucie Gaget on Apr 4, 2018 | 0 comments

We saw in a previous blog post that 3D printing is useful to print solar panels. But more globally, the 3D printing technology can help the energy industry for both prototyping and production, in diverse sectors and for many different applications. For example, renewable energy is becoming a priority and 3D printing could clearly help to develop new devices. But the additive manufacturing technology could help the energy industry even more globally: gas and oil companies, or creation of wind turbines and solar cells. Additive manufacturing is becoming a great ally of the energy industry.

What we can say is that 3D printing is allowing new experiments in many different sectors. In this blog post, we are going to see what are all the benefits of the 3D printing technology and we’ve selected a few examples of projects created thanks to additive manufacturing for the energy industry.

Additive manufacturing and energy

Using 3D printing in the energy industry

Prototypes and production

Additive manufacturing is becoming an efficient method to produce any devices, in any industry. The energy industry is not an exception! Indeed, this cutting-edge technology is now used to create energy devices and it is now an asset both for the prototyping and the production process. You will see thanks to the examples that we’ve selected that additive manufacturing can have a lot of benefits.

3D is allowing to work more efficiently on different levels. For example, you can use 3D printing, but you could also just use a 3D modeling software to get a better visualization of your project, or create new simulations. But you could totally use 3D printing to create models of your energy projects in order to get a better visualization for you, your team but also for you customers.

Customized parts at a lower price

If additive manufacturing is attracting a lot of companies, it is because this manufacturing technique creates parts totally adapted to your needs. It will fit your projects quite easily as you make custom parts.

Last but not least, if additive manufacturing is more and more present in the energy field to create reliable and sustainable devices, it is also because it is a cost effective method, especially for the prototyping process. It will allow you to make as many iterations as you want.

Developing new devices using 3D printing

We already saw in a previous blogpost that 3D printing is quite a revolution for the renewable energy industry, as it is helping to create new devices such as 3D printed solar panels. We discovered that these 3D printed solar panels are 20% more efficient than regular solar panels. The work on new materials and new designs is allowing to get more efficient devices. New 3D printing materials are developed, like for example, there is a new way to conceive solar panel and photovoltaic (PV) cell manufacturing. It is possible to print solar cells to collect solar energy.

If you want to 3D print for energy, you have various possibilities, but you have to get 3D printing materials with special properties. It clearly depends on the final use of the parts, sometimes, these parts have to resist stress, pressure, chemical products, or heat.

The best projects made thanks to 3D printing in the energy industry

Here is a selection of the best projects regarding the energy industry using 3D printing. Thanks to these example, you will get an overview of what it is possible to do in the energy industry today, using additive manufacturing.

3D Printing for solar energy

3D printed palms to collect solar power

A company in Dubai chose to 3D print the parts of their Smart Palm trees project. The idea is to create some stations in the street, on the beaches, where people will be able to recharge their phone, access wifi, etc. These trees have an elaborated design and will collect solar power for anyone.

https://inhabitat.com/

The 3D printed version of these Smart Palms will be made with fiber reinforced plastic. First, it has been planned to create them with steel, but the creators were also looking for lighter materials to 3D print this project, that is why they choose to 3D print them.

Watch the video below to get more information about these Smart Palms:

Simusolar

At Sculpteo, some of our customers are working on solar energy using 3D printing. On the blog, we already told you about Simusolar, a company created in 2014 and willing to bring solar energy to the rural population of Tanzania. They develop and implement small-scale sustainable solutions to help local people in their everyday life. Check out this blog post for more information about the project.

They decided to use 3D printing because they needed a lot of custom made parts. Their clients are farmers, fishers, or rural residents looking for various equipments powered by solar energy.

In the video below, you will see the testimonial of one of their customers, explaining how solar energy changed his daily life. Discover the project here:

Simusolar Intro from Michael Kuntz on Vimeo.

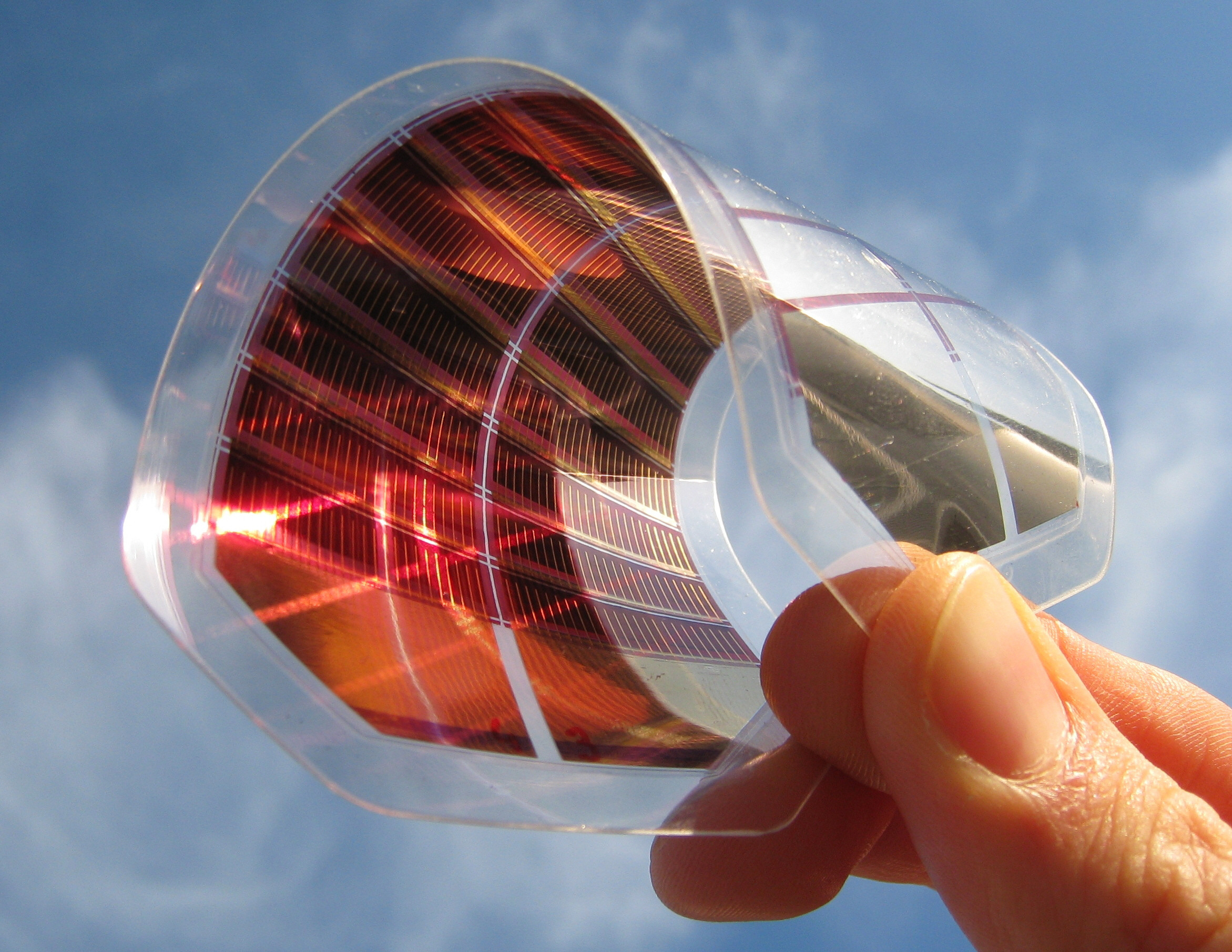

3D printed solar cells

At the CSIRO (Commonwealth Scientific and Industrial Research Organisation) they use industrial 3D printers to print rolls of solar cells. These Australians scientists succeeded in creating A3 sheets of solar cells, that can be used on many different surfaces such as windows or buildings. It really offers new possibilities. These are truly efficient solar panels and the 3D printing technology helped them to produce an accurate system. We know now that solar panels made with 3D printed solar cells are 20% more efficient than traditional solar panels.

3DPrint.com

These solar cells are the largest ones, and they are created with flexible lightweight plastic. The scientists developed a photovoltaic ink, that they drop off on the flexible plastic strip. This whole process includes gravure coating, slot-die coating and screen printing.

3D Printing for wind energy

3D printed micro-turbines

This manufacturing process allows to create new wind turbines. These are efficient devices but Orange Silicon Valley made an experiment: they wanted to see what it was possible to do with micro turbines and what was the best method to manufacture them.

Traditional wind turbines are really difficult to transport, that is why they decided to create micro-turbines. It will be possible to send these turbines more easily in areas where people can’t use traditional turbines. For example, these micro-turbines are perfect for urban setting!

To create the prototype of this project a desktop 3D printer has been used, using ABS plastic.

3D printed wind turbines

A startup had the idea to develop the use of 3D printing to manufacture wind turbines. As we just said it, it is really complicated to transport a wind turbine. The goal of the project developed by RCAM Technologies is not to make a micro-turbine, but a much taller turbine. Indeed, if the wind turbine is taller, it will be even more efficient. The idea here is simply to 3D print some parts of the wind turbines on spot.

With the quick evolution of XL 3D printers, it is now possible to print bigger projects, and to manufacture them directly on spot. This project could allow to create taller wind turbines. In other words, 3D printing could help to create more efficient wind turbines. For the moment, the test is to 3D print the prototypes of the wind turbines using a robotic arm.

3D printing for batteries

Rechargeable batteries made with graphene

We already saw this, but 3D printed batteries are a reality and they are even faster and cleaner. Researchers for the Manchester Metropolitan University, and University of Chester and Central South University in China actually created a new energy storage device.

Inside of these devices, the disc electrodes have been 3D printed using graphene. If you don’t know about this amazing 3D printing materials, check out our blog post about graphene. It is showing that it is becoming possible to get a little bit of freedom regarding the designs of electrical devices, and it will offer new possibilities regarding energy. It also becomes possible to use many different printing materials, adapted to the projects. This little discovery is actually a new method, much easier and viable to store renewable energies.

3D printed liquid batteries

IBM and ETH Zurich researchers created the first liquid battery that can produce energy and cool at the same time. It is called the “redox flow” battery and it has been created thanks to the 3D printing technology.

The team of researchers actually used 3D printing to produce a micro-channel system to supply the battery with electrolytes. It minimizes the need of pumping power and this system eliminates internal high temperature.

3D printing for gas

Siemens and the 3D printed turbine blades

Engineers from the Siemens facility in the UK decided to 3D print the finished blades of their gas turbines. These blades have to resist to intense pressure. The 3D printed turbine blades travel over 1,600 km/h, and can withstand 1,250°C of surrounding heat with rapid cooling at 400°C.

https://www.siemens.com/innovation/en/home/pictures-of-the-future/industry-and-automation/additive-manufacturing-3d-printed-gas-turbine-blades.html

What are the advantages of the 3D printing technology to manufacture these kind of equipments? By using this technology, the process to manufacture the blades was up to 90% faster! This is a typical example of how 3D printing can be used to create parts of equipment for gas or oil companies.

Steel components are expensive and 3D printing can be the solution, as it is a great method to manufacture parts totally adapted to the machine you are using. You can make any parts, to any dimensions. This tribune affirms that by 2019, 10 percent of oil and gas companies will be printing parts and equipments. The future of the use of 3D printing for the energy industry is really promising.

We hope that this overview helps you to see what are, more concretely, all the benefits of 3D printing for the energy industry. Are you ready to try additive manufacturing to prototype or produce you energy projects? You can upload your 3D model right now on our online 3D printing service and access our professional 3D printers.

If you want to receive more information about 3D printing applications, don’t forget to subscribe to our weekly newsletter.

Credit: https://www.siemens.com/innovation/en/home/pictures-of-the-future/industry-and-automation/additive-manufacturing-3d-printed-gas-turbine-blades.html

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook