Laser cut acrylic: The 8 best projects!

Posted By Jessica Van Zeijderveld on May 18, 2018 | 0 comments

In one of our recent posts we hope to have inspired you on the use of laser cut wood for one of your next laser cutting projects. If you haven’t read it yet, you can find 10 amazing laser cut wood projects here! Now, we would like to inspire you regarding a different laser cutting material, acrylic. Acrylic has several benefits and interesting technical properties which we will explain first in this blog post. After that, we will show you some examples of companies and professional designers who have already implemented acrylic for their laser cutting projects and products. After giving you some inspiration, we will explain to you how you can start your very own acrylic laser cutting project today, here at 3D printing and laser cutting service Sculpteo.

What is laser cutting?

The laser cutting process includes processing a 2D file into a real life object with the help of a high-powered laser beam’s output, generated through optics and then directed onto a small zone of material – in this case, acrylic. This laser source can then cut and engrave the material according to the 2D file’s cutting lines with high precision – even being able to cut parts with a thickness up to 10mm. As for the required 2D file, you can use a 2D vector file for the laser cutting process, made with vector graphics software. You can find a lot of free 2D laser cutting files on online marketplaces. Find a list of these marketplaces here.

The benefits of laser cutting and engraving

If a rapid production form for your company’s product line is important, laser engraving and cutting can be a great solution. Traditional manufacturing methods are not very efficient and precise when it comes to parting or cutting a specific material or an area of a material. However, a process that involves a precise laser system is very effective, and cost friendly. It saves material due to its precision and it can cut a wide range of complex parts, thicknesses, and other kinds of laser cutting materials.

Laser cut acrylic

The process of laser cutting acrylic involves a focused acrylic laser that gives off heat – allowing to partially melt the specific area and outlining of an acrylic surface. The computer and cutting technology behind this laser will direct the laser on a pre-programmed path that is included in the 2D file.

The material itself has many benefits when it comes to its ease of use and its durability. Acrylic’s mechanical properties are influenced by the chosen thickness but no matter the thickness, the material will stay stable and high in resistance against bumps and cracks. Acrylic is also waterproof so it can be applied to projects that may be subject to water or similar liquids.

The best laser cut acrylic projects

Of course, there are already companies, designers and engineers out there that made use of laser cut acrylic. Below, you can find some examples which allow for you to see for yourself why using laser cut acrylic was ideal for that specific project:

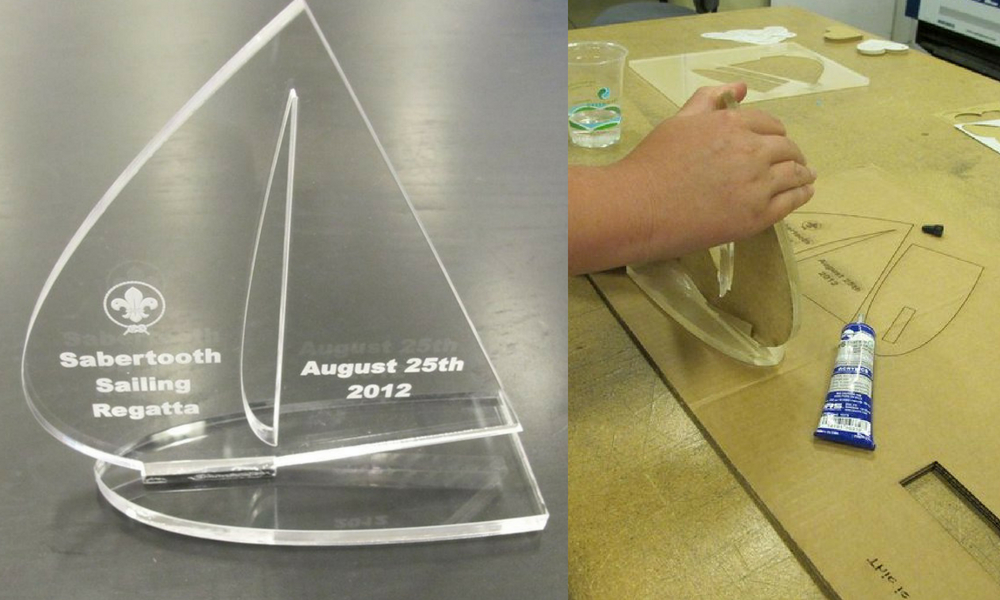

1. Acrylic trophies

Credit: https://www.instructables.com/id/A-Quick-Laser-Cut-Sailing-Trophy/

Created by professional designer Sean James, this laser cut trophy is made out of acrylic material and it was meant as a trophy for a sailing competition. It is hard to distinguish this trophy from an expensive trophy made out of glass. It was made out of a 3/8″ Thick Clear Acrylic 12″x9″ Sheet and it only took him 30 minutes to laser cut it! With only a bit of glue and some focus, Sean had a proper looking trophy.

2. Laser engraved Nokia project

Credit: https://www.cutlasercut.com/showcase/laser-engraved-acrylic-signal-noise-for-nokia

Indeed, even a big company like Nokia uses acrylic but for laser engraving this time. Although the project came higher up from Nokia, it was forwarded to marketing bureau Hyper which then gave the project over to Signal | Noise. This company created a digital poster that was not only laser engraved with acrylic material, but had also graphics in the form of floating data projected onto it. The data itself was from Nokia’s cooperation with Burt’s Snowboards. This data had captured real-time information on speed, altitude, heart rate, galvanic skin response and orientation of snowboarders.

3. Diva Arts

Credit: https://www.cutlasercut.com/showcase/acrylic-laser-cutting-service-diva-ar

Diva Arts, founded by Chantal Freeman, creates memorable branding and messaging signs from acrylic material meant for arts organisations, charities and small businesses. The product in the picture above was meant for the company Slowburn who developed icons to engage and attract visitors to their tent at a venue at the Greenbelt Festival in 2010.

4. Furniture from Alex Hammond

Credit: http://www.cutlasercut.com/showcase/laser-cut-furniture-alex-hammond

The Alex Hammond studio is a studio that is focused on product and packaging design. To turn the tables, they have decided to create some furniture as well. This tube table that is shown above, is made from laser cut acrylic. The acrylic was cut from 3mm white acrylic. This cut was then placed between two sheets of strong glass to be then mounted on a minimalist powder-coated steel frame giving the table its unique look.

5. Laser cut acrylic rings

Credit: https://www.instructables.com/id/Laser-Cut-Jewelry-Layered-Acrylic-Rings/

These customer laser cut acrylic rings created by a professional designer from Timelab, look as if they could have been purchased from a proper jeweler. According to the designer on the use of color, he found that the best effect is reached with transparent colors (such as amber, brown, dark blue and violet) and translucent colors. To get one ring to consist out of multiple colors, 3 acrylic sections are laser cut and are then glued together.

6. Lamps made from laser cut acrylic and wood

Credit: http://www.cutlasercut.com/showcase/laser-cutting-product-plywood-massow-design

Barend Massow is a one man company that creates unique lamps. Yes, these lamps are not only made from laser cut acrylic, but also from laser cut wood! Plywood, to be exact. Would you like to know more about laser cut wood, click here.

7. Howkapow jewelry

Credit: https://www.cutlasercut.com/showcase/howkapow-laser-cutting-jewellery

Howkapow jewelry was founded in 2010 and sells acrylic laser cut jewelry to independent sellers. The designer behind Howkapow, Cat How, uses a combination of solid colours and printed acrylic for parts. When the parts are laser cut, it is finished off with a small raster engraved logo.

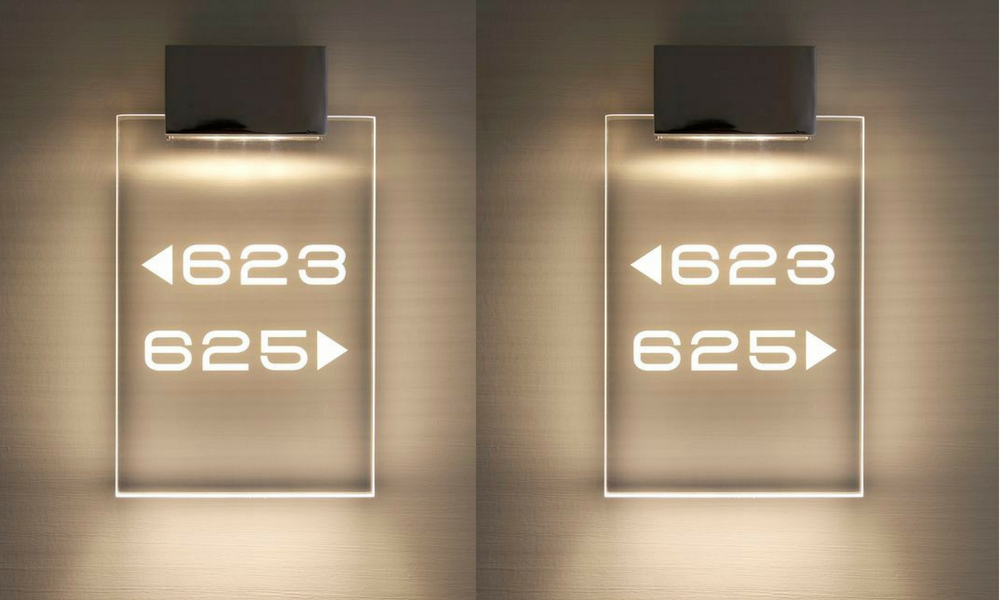

8. Hotel room signs

Credit: https://www.ponoko.com/blog/design-ideas/laser-cutter-projects-ideas

A futuristic and sleek looking room sign that can represent a modern and pragmatic hotel or business. This sign is made out of acrylic material and directs the guests at the Galaxy hotel in Greece, to their rooms. Due to acrylic’s glass-like nature, a light could be implemented and spread around evenly by the acrylic surface.

Acrylic material at Sculpteo

Here at Sculpteo, we use sheets of acrylic that were produced by using the ‘’continuous cast method’’ also known as CCA. This process allows for benefits such being able to make a material transparent and optically clear. This process is also used for creating glass in general. Another benefit of CCA is having stronger products, making them easier to ship and transport. Our acrylic has a smooth glass-like surface with a shiny look to it. This surface can range between transparent and moderately opaque. When we laser cut acrylic, the material is not prone to any deformation and thanks to its smooth surface, a perfect and precise cut is easily achieved. Sculpteo’s acrylic even lights up when LED lights are added to the mix!

Laser cutting acrylic at Sculpteo

Now that we have given you some inspiration for laser cutting acrylic, we hope to have shown you how ideal it is to use it for the creation of your products. Not only is our acrylic quite inexpensive, the precision of the cutting only is really what makes it worth it. Laser cutting is easy, quick with its cutting speed, precise, saves material due to its precision and it can cut a wide range of different parts, thicknesses, and laser cutting materials! Are you ready for your next laser cut acrylic project? You can upload your file today, here at Sculpteo 3D printing and laser cutting service. We look forward to seeing how creative you are with our laser cutting technology!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook