Fabpilot unveils FDM integration

Posted By Carmel Rouhani on Jun 7, 2018 | 0 comments

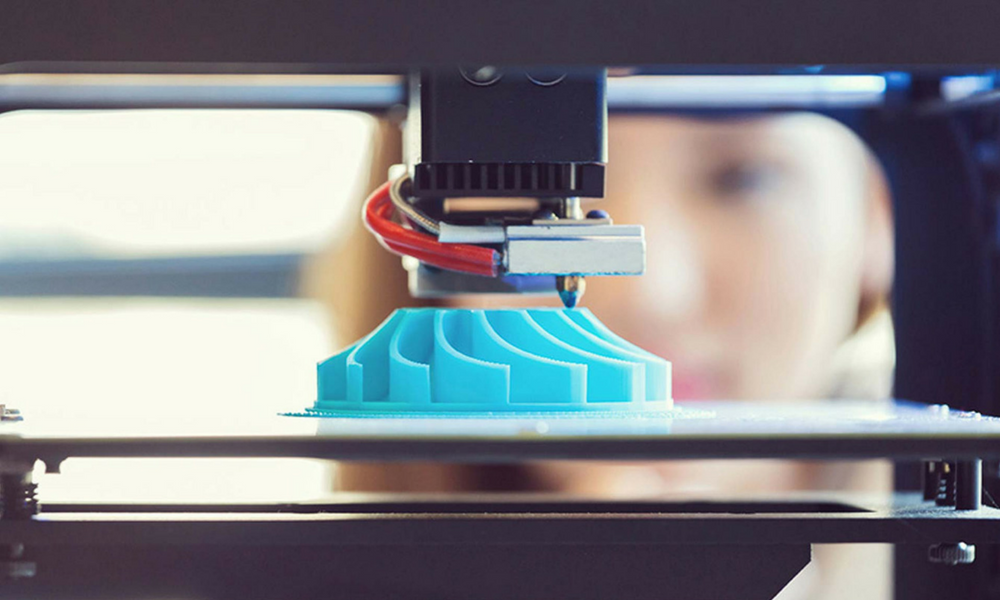

Fabpilot 3D Printing software, a leader in SLS, MJF, and Powder-based technologies announces a game-changing development in FDM production management.

Sculpteo’s initial entry into the 3D Printing software market was focused on high-output service bureaus and internal labs using SLS, MultiJet Fusion, and other Powder-based technologies. With the development of advanced 3D Nesting, review and repair 3D tools, and high-volume workflow management tools, Fabpilot was designed to overcome many of the challenges Sculpteo faced on a daily basis.

Fabpilot breaks into new markets

With the upcoming development of FDM integration, Fabpilot now aims to support the organization of 3D printing for Fablabs, Makerspaces, Educational Programs, and other businesses providing 3D printing services. These types of 3D Printing labs now have the opportunity to combine file analysis and repair, quotation, part/order management, and performance analytics with direct printer integration for nearly any FDM printer (must be able to run Marlin firmware and have a USB or micro-USB port that allows for serial connectivity). With direct printer integration, lab managers can now control end-to-end production using FDM from the same cloud-based platform.

How does it work?

Production or lab managers can grant access to designers and clients to create a project and upload more than 30 different file types (including native CAD) to the cloud-based platform. The designer/client can repair files, review the solidity, apply lattice optimizations, set optimal orientation, add supports, get a pricing estimate and place their order all from the same platform. With a collaborative platform and shared file review, production engineers and designers work together to review files from any web-connected device. With cloud-slicing, slicing is done on the server-side and gcode is sent directly to the printer, no more SD cards with gcode or manually uploading to the printer interface. Fablabs, Makerspaces, and educational programs will be able to print directly to multiple printers which can even be remotely located.

What to expect

- Cloud slicing: Upload 30+ file types which are then sliced and toolpaths defined. The gcode is ready to be sent to the printer

- Print directly from the cloud: With slicing completed in the cloud, the gcode is sent directly to the printer. You no longer have to download the gcode and manually upload it to the printer.

- 2D Nesting: You can now arrange the maximum number of parts on the build plate while avoiding a collision. Reduce the number of jobs required to print your parts.

- Multi-machine control: Automatically assign jobs to available printers

- Optimize orientation: Use Fabpilot’s existing automatic orientation algorithm to minimize the need for support structures by finding the optimal orientation

Complete, integrated, collaborative

Nowhere else does this combination of advanced 3D tools and production workflow tools exist in a single platform. Production managers, academic program administrators, and 3D engineers will be able to benefit from this streamlined platform for end-to-end 3D printing workflow management. Reduce the amount of different software in your workflow and simplify the 3D printing process.

If you manage a Fablab, Makerspace, educational 3D printing lab, service bureau or internal lab using FDM technology, this is the perfect opportunity to optimize your production workflow.

Find out more and guide product development

Join our Newsletter list to be the first to hear about these developments as they are deployed

Help us understand your software needs for FDM technology and drive Fabpilot’s development roadmap by providing your feedback in our short survey. To show how much we value your feedback, anyone who completes the survey will receive ONE FREE MONTH of Fabpilot after the trial. Take the survey here

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook