4 ways to reduce cost of production and prototyping with 3D printing

Posted By Lucie Gaget on Jun 14, 2018 | 0 comments

3D printing is a time saving and money saving manufacturing technique which could totally help you to improve your manufacturing operations. In this blog post, we are going to focus on the money saving aspect of additive manufacturing. Using 3D printing could be an amazing way to reduce your costs for prototyping, but also for production. It can reduce the cost of the parts that you are producing, but also the costs of the whole manufacturing process. Let’s see how this technology can help you cutting costs. We are also going to offer you our best tips to save money while 3D printing, to help you make the most of this cutting-edge technology. Discover the ways to reduce cost of production and prototyping thanks to additive manufacturing.

How can 3D printing help your company to save money?

3D printing can allow you to improve your products and to produce at a lower cost. You can create lighter devices, work on the design to get more efficient parts, more adapted to your use. Keep in mind that 3D printing your product will considerably help to reduce your costs on different levels. Including 3D printing in your prototyping and production process could clearly help your company. Let’s see more in details how all of this is impacting your manufacturing costs and will help your company to save money.

Reducing tooling investment

More than the price of the individual part, 3D printing is allowing to make you save money on the whole manufacturing process. Additive manufacturing can be a way for you to rethink totally your manufacturing process and allow an improvement of the supply chain. For instance, the assembly line and tool manufacturing can be improved thanks to the additive manufacturing technology.

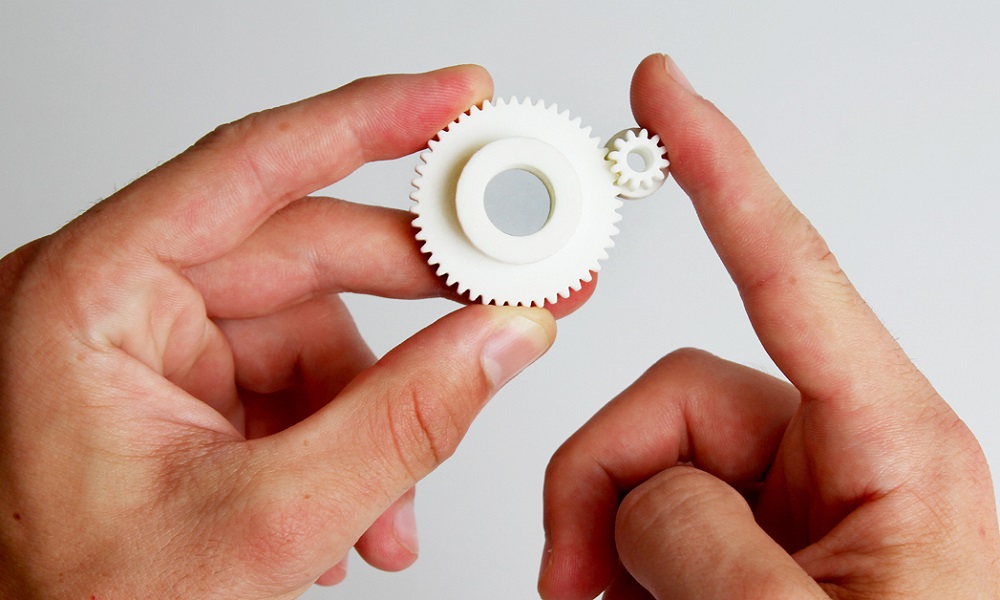

3D printing is helping to reduce tooling costs, for example, 3D printing is a great way to manufacture tools directly, or to skip some assembly process by printing devices in one part. The car manufacturer Opel admitted a tooling cost reduction of 90% for the assembly process. Other example, Jabil’s Auburn Hills facility is also using additive manufacturing and is now noticing 30 % of reduction in the cost of tooling, which is quite important. It depends of your business and of your use of 3D printing, but it is obviously a way to cut your costs when it comes to tooling.

Accelerating the product development process

3D printing is an amazing prototyping method, it will help you to create many iterations in no time, and for a lower price. Indeed, with traditional manufacturing methods such as injection molding, you will have to get a mold created before printing your product. This process is expensive and takes a lot of time. While using additive manufacturing, you just have to prepare a 3D file that you are free to modify by yourself to make different iterations of your product while prototyping. It is an amazing asset for your product development process

Moreover, additive manufacturing is allowing to make devices that would have been too difficult to produce with a traditional manufacturing method, such as complex designs. It will take less time to develop this kind of project using additive manufacturing. By saving time in the development of your project, you will obviously save money.

Optimizing your design

If you want to use 3D printing, you will have to optimize your 3D model for 3D printing. Working on the product’s design can allow you to optimize your 3D printed part and reduce its cost. An efficient design can help you to save money. Indeed, while creating your model with your 3D modeling software, you can elaborate a design that could be really optimized and use the minimum quantity of material needed. For example, you can use lattices or honeycombs designs or these kinds of design to reduce your manufacturing costs!

Moreover, if you have a well-designed 3D printed part, it will clearly minimize post-production steps that add cost and time to the development of your product. It will help cutting production costs!

Using cheaper materials

Using a 3D printing service such as Sculpteo is offering your company the possibility to make a choice between a lot of different 3D printing materials. You can reduce material costs thanks to additive manufacturing.

All these materials are different, and have different properties. You will have to find the best material for your project. For example, for your prototyping process, you can use our cheapest option, the raw material Multi Jet Fusion PA12.

Going further with cost reduction: Our tips to reduce your 3D printing costs

3D printing costs: How does it work?

Here are the aspects that you have to take in account when you 3D print your project, it will help you to understand how additive manufacturing can be great for cutting manufacturing costs. While uploading your 3D file on a platform such as Sculpteo, the quote that you will get will be based on factors such as:

The material: The same 3D printed part will not have the same price with a different material. For example, a part printed with the Multi Jet Fusion PA12 will be way much cheaper than an object 3D printed with a metal material.

The volume and complexity of your part: If your print a big part, you will use a lot of powder and take more space in the 3D printer. That is why printing bigger volumes will increase the price of your 3D printed part.

The post-processing and finishes: All of this additional work has to be taken into account, like powder and support removal, the cleaning process, or even the finishes that you chose during your order!

Reduce your 3D printing costs right now!

Here are some advices that you can use while uploading your 3D files on our online 3D printing service. It could clearly help you to reduce production cost.

Find the best 3D printing materials for your project

We just saw it, the price of your 3D printed parts largely depends on the material that you will choose to 3D print your object. If you are looking for the cheapest option possible on our online 3D printing service, you can use the Multi Jet Fusion PA12 in its raw version. Check out our full Q&A on this new option.

Scale down your model

For prototyping, if you need the visual aspect, the size of your model is not that important. If it is not crucial, you can scale down the size of your 3D part. Indeed, if your part is smaller it will obviously reduce the costs as it will use less powder!

Hollow your part

While uploading your 3D model on our online 3D printing service, you can access our hollowing tool. How does it work? By placing two holes on your design, you will be able to get a hollowed part. This way, it will be possible to remove all the powder that is inside the model, and your part will be hollowed. You will use less powder, so your parts will be cheaper.

Use our Batch control tool

If you are planning to print more than 20 units using Sculpteo 3D printing service, you can use the batch control tool. This tool can help you to optimize the space available in the 3D printer. The less space you will take, the cheaper your order will be. Think about it for you next order.

Reducing manufacturing costs, process optimization, etc, all these are goals that you can easily reach while using additive manufacturing. We hope that this blog post helped you to see more clearly the benefits of additive manufacturing for the budget of your company, and that you won’t hesitate to make the most of our tips to reduce your costs while printing.

Ready to reduce production cost? Upload your 3D file on our online 3D printing service right now.

For more tips regarding the use of additive manufacturing, please subscribe to our weekly newsletter!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook