5 Best 3D printed boat projects

Posted By Jessica Van Zeijderveld on Jun 27, 2018 | 0 comments

Boats are used for many important aspects to our society. They are used not just near the coast, but in cities like Venice and Amsterdam as well. Crucial for not only getting from point A to B but also e.g. to retrieve data for marine biology and to catch (shell)fish, an important food source. Boats can vary in size, build and material usage so, in this blog post, we will show you examples of boats made with the help of additive manufacturing. We will tell you a bit more on why you should 3D print boats or parts of boats, what organizations have created 3D printed boats and how you can start your own 3D printed boat project today, here at 3D printing service Sculpteo.

Benefits of 3D printing boats

3D printing boats come with many benefits. Crafting boats go back to ancient times and along different parts of history, new manufacturing methods have come to light. From hand labor to automated machining, each boat can be uniquely produced. With 3D printing, boats can be produced lighter, with no material loss, parts can be customized and parts can be easier to replace. These are the general benefits. Below we will explain to you each benefit in detail.

No material loss

Additive manufacturing solely uses the amount of material that is needed to build your boat without having excess material that will go to waste. The excess material will be used for a different printing job. When using traditional subtractive manufacturing methods, material will be wasted, making it a less sustainable and costly manufacturing method.

Customized boat (parts)

Boats have different purposes, some focus on their speed and others focus on their balance. In order to not only create uniquely designed parts, customization can also be used to create parts in a way that will optimize the boat’s overall performance such as create the perfect skeleton. Customization with 3D printing is beneficial in a way that it doesn’t cost anything extra whereas it would cost a lot with traditional manufacturing methods. Simply adjust the 3D model to your liking.

Your boat will be lighter

Additive manufacturing produces parts lighter compared to when it is made with a traditional manufacturing method. This has to do with the fact that 3D printing materials are lighter and because 3D printing only uses as less material that is needed. Once a boat weighs less, it will be able to perform better becoming faster and becoming more balanced.

Quick replacement of spare boat parts

The waters can be rough and unforgiving to boats and ships. This roughness often leads to damaged parts or bumps in the boat hull. Boat hulls also get very dirty which can be nearly impossible or very expensive to clean properly, making it more logical to replace it in total. Once damaged or dirty, the boat hull will lose speed or effectiveness. With additive manufacturing, parts can be fixed quickly and at lower costs compared to a brand new hull.

Some companies such as Ivaldi Group are working on improving 3D printed maritime spare parts, and even on the texture of spare parts for advanced performance. They found that texture was improving the functionalities but also the perception of the quality of the part.

5 Real-life examples of 3D printed boats

Although 3D printing is currently being used quite a lot for the automotive industry, the shipbuilding industry has just started out on a smaller scale. Below you can find some organizations who have 3D printed boats for special purposes:

#1 3D printed marine hull

This LSAM 3D printer is used to create large objects – ideal for creating a full-scale master plug boat hull. The master plug of the hull of a marine boat, including the print, its assembly process, and its trim process took less than ten working days to complete! Once the printing process was done, and the hull was coated with a finish, a fiberglass mold was implemented by tracing along the pre-printed pattern. The material that was used was the Techmer Electrafil© ABS LT1 3DP, a specific 3D printing material optimized for shipbuilding. Creating this hull with 3D printing optimized the feasibility, practicality, and the economics behind it.

#2 3D printed concrete canoe

Source: https://3dprint.com/178972/3d-printing-concrete-canoe/

Chances are high that you have never heard of it, but the Concrete Canoe Regatta in Germany is a two-day-long race making use solely of concrete canoes. 90 canoes to be exact, brought to motion by 1,000 participants from universities all over Europe. Three-times champion winner ETH Zurich has won once again with their 114-kilogram 3D printed concrete canoe made by 3D printing a thin plastic skeleton which was then used to cast the framework of the canoe in concrete material. The point of using 3D printing was the benefit of being enabled to create a geometrically complex 3D printed shape to be cast in concrete. This shape allowed ETH Zurich to the be the fastest. The materials that were used were transparent PLA and it was created with the FDM 3D printing technology.

#3 3D printed boats for naval missions

Source: https://3dprint.com/118361/3d-printed-robot-boat-swarms/

Technology and 3D printing are tied together so it comes to no surprise that 3D printed objects are combined with other technologies. Researchers from the University of Lisbon have created swarms of robot ships that have technology inside of them, a Raspberry Pi 2 computer including a compass, GPS, and WiFi to be exact, which allows for the ships to think for themselves. The boats are 330$ each and were created with 3D printed parts and CNC-machined polystyrene foam. The goal of these ships is for them to be used for naval missions. Swarms of these ships receive a pre-programmed goal before being put on the sea which means that they will communicate with each other in order to navigate. 3D printing allowed for the easier implementation of the technological aspect of these boats and it kept the costs in check.

#4 3D printed yacht hull

Source: https://all3dp.com/worlds-first-10-meter-long-3d-printed-yacht-hull/

HanseYachts AG is a German yacht manufacturer that is implementing a 10-meter long hull created by a 20-meter long hull 3D printer in their product line. This yacht hull will be part of their Hanse 3D15 yacht. “The new Hanse 3D15 will thus be a wooden yacht. With the new hull print production, we want to manufacture not only more powerful hulls but also reduce the production times significantly in order to satisfy the high demand of our customers. As a result of the 3D print, the Hanse individualization concept can be implemented in every possible way.” – Karl Dehler, chief engineer of the department for future development. The material that was used was wood filament that was made up of 60% recycled wood and a polymeric binder.

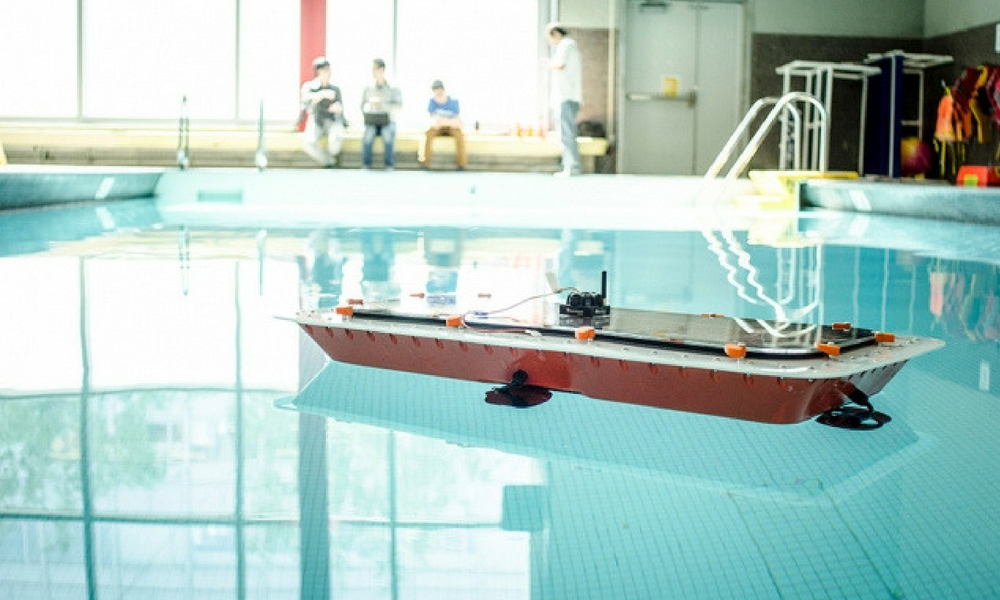

#5 3D printed autonomous boats to reduce traffic

Source: https://3dprint.com/214729/3d-printed-autonomous-boats/

Cities like Venice and Amsterdam highly rely on boats and ships as a form of transportation due to the city’s structure demanding so. Due to the increasing amount of tourists visiting these cities, many problems arose with the waters being filled with boats. MIT’s Computer Science and Artificial Intelligence Laboratory and the Senseable City Lab in the Department of Urban Studies and Planning have combined forces in order to create smaller scaled 3D printed prototype versions of a rectangular boat that can move along a pre-programmed path. The goals of these boats are to obtain information with their environmental sensors and to provide city services during times when the waters aren’t as busy albeit overnight or during the day. The boats were 3D printed in 16 pieces and the total printing process took 60 hours.

Printing your boat project at Sculpteo

As you can see, 3D printing is applied to boats and ships for many different reasons. If it is not to improve its speed, it is to create a perfect skeleton outline or to combine highly advanced technology. These reasons alone are explanatory enough for organizations to use 3D printing for parts of their boat or ship. Do you have an idea for specific parts of your boat or product line you wish to 3D print? Upload your 3D file today at 3D printing service Sculpteo and we will get right to it!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook