3D printing in the automotive industry: Discover the 3D printed tires

Posted By Lucie Gaget on Jul 13, 2018 | 0 comments

Additive manufacturing is taking more and more space in the transportation sector and we are even starting to dream about fully 3D printed cars. In the meantime, we saw that the automotive industry is making the most of the 3D printing technology, by manufacturing car components. In this blogpost, we are going to focus on 3D printed tires, an alternative to our traditional rubber tires. For the moment, this technology can be used to develop tires for cars or bikes, but in the upcoming years, it will certainly revolutionize the whole transportation sector. Innovations, new features, automotive companies are working on new tire concepts to develop the wheel of the future to face new challenges and answer to customers needs.

How can 3D printing improve tires manufacturing? How can it optimize the product itself by making it more eco-friendly? Let’s discover all the information you need to know about 3D printed tires right now.

3D printing parts for transports

From cars to bikes, additive manufacturing can help to create amazing components and help manufacturers with their prototyping and production process. Here are the main benefits of 3D printing for car or bike components such as tires.

Mass-customization

3D printing is allowing mass customization, as it is really easy to make many iterations on the same product and to adapt it to your needs. For the automotive industry, additive manufacturing is a way to create spare parts for example for models that are no longer available on the market. 3D printing really facilitates this process. Thanks to plastic and metal 3D printing, these car parts are totally 3D printable.

Optimizing the products

3D printing is offering new possibilities regarding the designs, and we are going to see it later in the blog post, it is really useful to develop new concepts of tires. A lot of freedom is involved when it comes to manufacturing using the 3D printing technology. You are free to create any shape or design while using this cutting-edge technology. Digital manufacturing is a great way to rethink totally the design of common parts, such as tires, in order to improve their capacities, but also their impact on the planet.

Saving money

3D printing is obviously a cost-saving method to prototype, and even to produce your projects. Doing some rapid prototyping for your products using additive manufacturing will help you to reduce your product development budget. Indeed, to create your different iterations, you will just have to modify your 3D model using a 3D modeling software and print it again. Moreover, for the prototyping process, you can access really cheap material, with a really good quality such as our non-dyed Multi Jet Fusion PA12.

Reducing material waste

Material waste is a really important thing when it comes to manufacturing. Additive manufacturing is perfect to reduce material waste. It is quite an eco-friendly process. When 3D printing a product, you only have to use the precise amount of material that you need to create it.

For all of these reasons, this technology has a lot to offer to the automotive industry, bicycle manufacturers, etc. For example, do you know that our designer team actually created a fully functional bike using digital manufacturing a few years ago. Indeed, 3D printing and laser cutting are great to develop this kind of project. 3D printing is allowing to create great functional and mechanical projects.

But now, car and bicycle tires could also be developed really soon using this cutting-edge technology.

The most innovative 3D printed tires projects

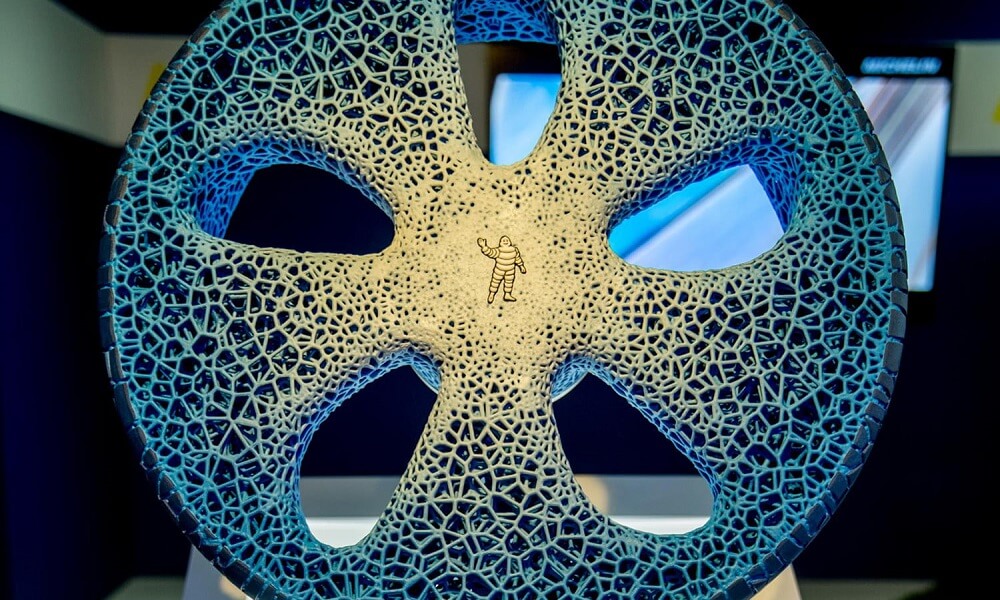

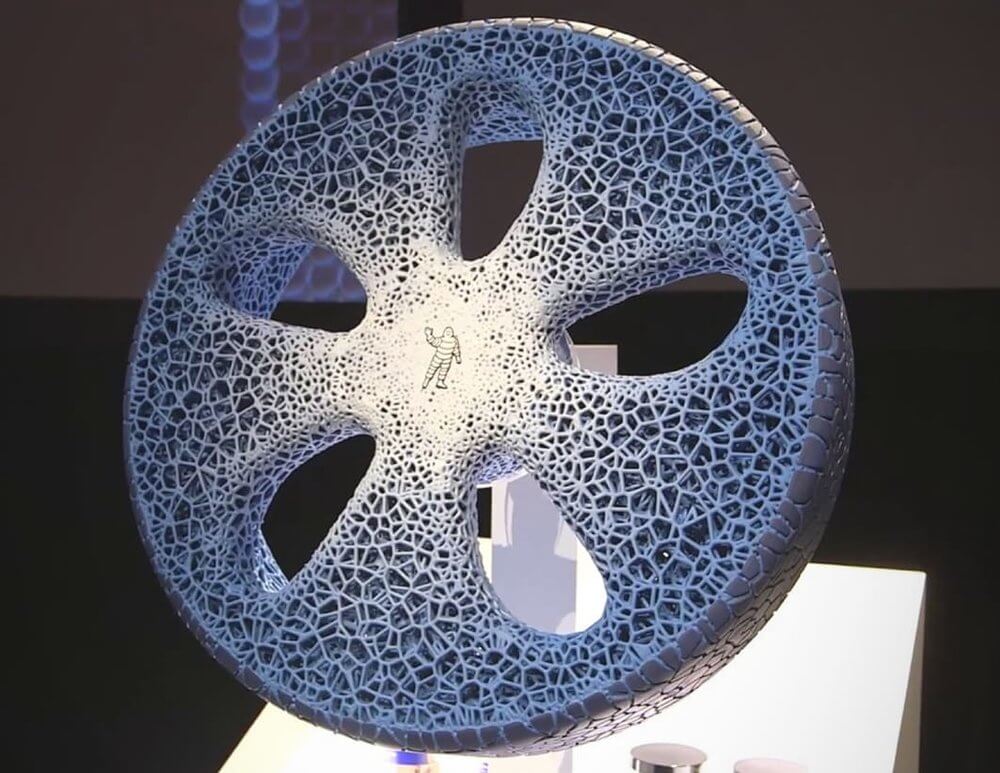

Uptis, Michelin’s airless tire

New innovative projects are unveiled regularly. The last one is the Uptis airless developed by Michelin. Michelin presented the first prototype and worked with the automotive manufacturer General Motors to create a first concept tire using 3D printing: the airless tires.

This new tire presents an incredible design, made to be airless to eliminate punctures. Utips aims to be biodegradable and equipped with sensors for real-time monitoring. Cleaner and safer, this tire also offers a new feature: the rechargeable tread. The tire can be reprinted on-demand, according to the need of motorists, for example, to adapt to winter and summer conditions.

Michelin, 3D printing biodegradable tires

credit: Michelin

Michelin is working on sustainable mobility, and creating new incredible printed tires using rubber, made of organic and recyclable materials. This car tire is called Vision. It is made to be an eco-friendly solution, but also to improve the product itself. Indeed, it is an airless tire. Without air, it is avoiding some traditional tire problems that we know, like low pressure, deflation or blowouts, but also safety problems.

Moreover, the manufacturer was inspired by nature to create this new tire, to create the shape and the design. If you want more information about how nature is inspiring 3D printing project, go check our last blog post about biomimicry.

3D printed airless bicycle tires

In the same spirit, some airless bicycle tires have been developed. These are actually flexible tires developed by BigRep studio. It has been developed with the will to create custom made 3D printed tires, that we can adapt to the needs of everyone.

>

These airless bicycle tires were created thanks to the 3D printing technology. For the moment, this experiment is quite a success, and is already offering a “smooth ride”, according to the riders who tested this BigReps prototype!

Goodyear’s 3D printed tire

credit: Goodyear

Goodyear is a tire manufacturer. They recently unveiled a 3D printed car tire project called Oxygene. This 3D printed concept tire is also an eco-friendly solution, made of rubber powder, from old tires. This 3D printed tire has been created using the Selective Laser Sintering (SLS) technology. The little inlets that we can see in the tire have been specially designed to contain moss, in order to absorbs= moisture from the road through the tread. This process also releases fresh oxygen through photosynthesis.

3D printed tires: What does it change?

Eco-friendly solutions developed thanks to 3D printing

The 3D printed concept tires that are developed by big companies are especially created for environmental reasons. Indeed, these tires are meant to be an ecological solution for this sector. In the automotive industry, one of the main concerns is actually to create new eco-friendly cars. We can see that, for example, with the development of electric cars.

Indeed, according to the Environmental Protection Agency, 75 percent of carbon monoxide pollution in the United States comes from cars. The additive manufacturing technology allows developing new eco-friendly solutions. Digital manufacturing is now offering new possibilities for the automotive industry, including tire manufacturing.

The European Union actually launched a 2.7 million euros project for car and construction for recycled 3D printer materials. It is made to encourage the researches and to produce greener materials such as biodegradable materials, for construction and car manufacturing. We can say that the environment is a real big concern for the automotive sector, but that 3D printing could be a real solution.

Wheels of the future

Additive manufacturing is an amazing method to improve the design of your product, but also the product itself. Indeed, it is the perfect manufacturing method to work on designs and try complex designs that would have been difficult to experiment with traditional manufacturing techniques. For wheels, it is making it possible to try new tires with beautiful and futuristic designs, perfectly optimized for the road and aligned with the eco-friendly ambitions of car manufacturers.

As you can see, additive manufacturing is making it possible to revolutionize the transportation sector by creating promising tire prototypes. Are ready to print your tires? If you need a good 3D software, for example, to create automotive projects, check out our selection of the best 3D modeling software for the automotive industry.

You can upload your 3D file on our 3D printing service, and make the most of our professional 3D printing technologies to give life to your automotive projects.

3D printing applications are numerous. Don’t forget to subscribe to our newsletter to discover all the biggest news from the 3D printing world.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook