Nature inspired 3D printing: Introducing Biomimicry

Posted By Kat Plewa on Jul 11, 2018 | 0 comments

Biomimicry might seem like a strange word, but the principals of it are fairly simple: bio- nature and mimesis- imitation. It’s a way to learn from nature and to incorporate its patterns and solutions into our designs. If you’ve never heard of it, we will introduce it to you in this blog post. Biomimicry is also linked to 3D printing, it helps us develop new materials which bring up new production possibilities. Not only that, biomimicry also provides us with answers for design optimizations and is inspiring engineers with new ideas for additive manufacturing. Discover possibilities biomimicry gives us right now!

What is Biomimicry?

Nature has been inspiring people for centuries. Nature finds perfect solutions for any problems and creates ideal structures to build up materials, some of which are the strongest mankind has ever seen, such as graphene. It provides us with food, fresh veggies and fruits, water, shelter and even medicine. But we can’t only take as there is so much more to learn from nature. It developed different structures to grow strong trees and fragile flowers, the perfect pattern on tiger’s fur and amusing capability to change colors for chameleons. We can observe the nature, learn from it, and use it to our benefits. That process is called Biomimicry.

Biomimicry revolutionizes 3D printing

Biomimicry beautifully corroborates with 3D printing. It can provide us with solutions for super strong and ultralight materials such as graphene, which is 10 times stronger than steel. Learning from nature can also allow us to use its patterns such as fish scale or the structure of grass on the cellular level to be used for better protection. Biomimicry empowers us to study nature, the structures that it created millions of year ago, and now can inspire us to develop new materials, build cars and even fix our bodies. In this blog post you will also find an example of nature being limited to the materials it uses and how, thanks to biomimicry and 3D printing, we were able to overcome it.

Copying nature to restore fertility

A collaboration of two Laboratories from Northwestern University Feinberg School and McCormick School of Engineering led to a successful study on bioprosthesis. The researchers started by examining collagen. It plays the main role for humans as it gives us structure. It’s also the abundant extracellular matrix in our body, but its architecture is too complicated. That’s where the gelatin comes. Gelatin is a hydrogel made out of broken down collagen, which makes it much easier to use. And thanks to the fact that it naturally appears in our bodies, it’s safe to use in humans. But the role of gelatin doesn’t finish just yet. A thorough study of the gelatin’s structure and the replication of nature’s own design gave a start to scaffold- the bioprosthesis. The engineers were able to use that material to 3D print prosthetic ovaries for mice. It was efficiently injected in mice who later gave birth. This study will hopefully lead to restoring fertility to young cancer patients, who were sterilized due to cancer treatment. That’s an amazing example of biomimicry and nature’s structures helping us to fix our bodies.

3D printed Foam Ink

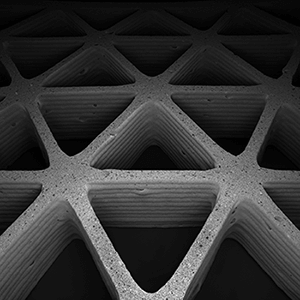

Researchers from Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), the Wyss Institute for Biologically Inspired Engineering at Harvard University, and MIT took interest in developing independently tunable material for 3D printing. The inspiration came to them from what we see every day- grass. It’s super lightweight, but at the same time very robust. It will bend when we step on it, but then it comes back to its natural shape. That’s thanks to its porous cellular microstructure as well as its hollow macrostructure. Putting both of those characteristics helped the scientist to work on ceramic foam ink. It’s a significant step forward as the material can be adjusted in macro and microscale allowing the production of tissue scaffolds, thermal insulation, and lightweight structural materials. In the Proceedings of the Natural Academy of Sciences, the scientists published their findings and introduced a new method to 3D print with ceramic foam ink. “By expanding the compositional space of printable materials, we can produce lightweight structures with exceptional stiffness,” said Jennifer Lewis, Hansjorg Wyss Professor of Biologically Inspired Engineering at SEAS and senior author of the paper. The ceramic foam developed by Lewis Lab is made out of natural materials such as water, air and alumina particles.

Foam Inks can be build of not only ceramics but also metals and polymers. Biomimicry comes here not only in what the ink contains, but also how it’s structured. “Foam inks are interesting because you can digitally pattern cellular microstructures within larger cellular macrostructures,” said Joseph Muth, a graduate student in the Lewis Lab and first author of the paper. “After the ink solidifies, the resulting structure consists of air surrounded by ceramic material on multiple length scales. As you incorporate porosity into the structure, you impart properties that it otherwise would not have.” Foam ink allows for the material to be multifunctional and hold different properties such as thermal or mechanical. Once the material’s characteristics were optimized and the ink had a specific microstructure, the scientists 3D printed lightweight triangular and hexagonal honeycomb structures with changeable geometry, density and strength. Biomimicry again brings excellent solutions for our needs.

How biomimicry changes footwear

Going a bit further than the material itself, Footprint Footwear, used a lattice structure, observed in wings of insects or leaves, to create 3D printed midsoles and insoles. The company uses different 3D technologies. They 3D scan the customer’s feet for the ultimate personalization of the shoes, then the 3D printed parts are made with Selective Laser Sintering (SLS). The lattice structures are vital in the shoes as the mid and insoles provide all the support for the feet and allow natural gait. They are designed automatically but can be modified specifically for each wearer, providing them with the most optimized and healthy walking experience. Nature has given us an excellent pattern to help us with everyday tasks.

Enjoyed that introduction to 3D printed footwear? Now we bring on the big guns.

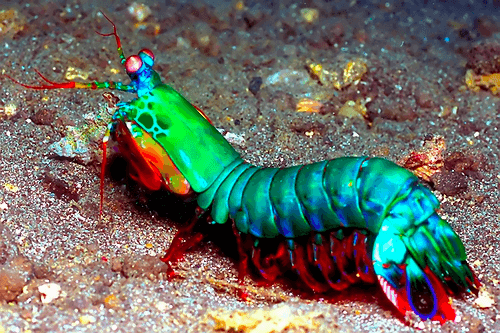

3D printed armor

Mantis shrimp, also known as a stomatopod, might not be the most beautiful thing nature has created, but what makes the little animal extraordinary is a raptorial appendage. It’s a fist-like weapon, otherwise called a ‘’dactyl club’’, and it gives the shrimp killer abilities to beat up the prey without much damage to the organic armor of the shrimp. The dactyl club is build up of herringbone pattern that has not been seen in nature before. It was discovered by researchers at Purdue University in collaboration with Bourns College of Engineering. This brings development to many different environments, including advanced manufacturing. It starts a new era of 3D printing materials. The design of nature’s herringbone structure could be copied to manufacture sever parts of airplanes or powerful armor. It’s spectacular how biomimicry learns from different species to provide us with solutions for our needs.

Scientists from Northeastern University College of Engineering took another take on how nature protects itself. Inspired by fish scales they focus on the flexibility of future 3D printed armors. Ranajay Ghosh, a researcher on this project, said ‘’The next generation of armor systems are light, perform a lot of functions, and at the same time do not compromise on protection. And nature provides very important information in terms of armor development. This is very different from what people have been working on before, which is focusing on the very nature of the scales themselves, how they will behave, and whether they break easily or not. Here, our focus is simply the effect of simple scales and their mutual contact and interaction with the soft substrate.” Researchers concluded that if they apply fish based scales in specific places on the soft material layer, it makes the surface stiff instead of elastic. The main factor for this research is what’s the perfect combination of different scale and substrate. This wouldn’t be possible without 3D printing and the variety of materials it provides, which allows people to overcome the limits of nature using its own patterns.

Nature-based engineering

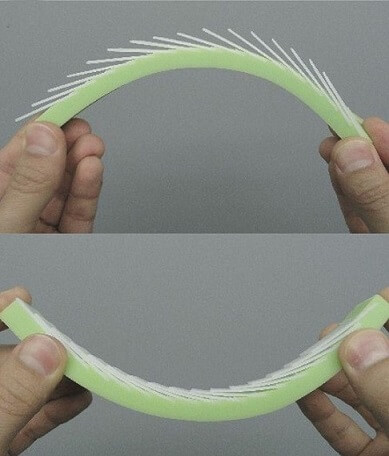

What links LCD and OLEDs screens? 1. You’re reading this blog post on one. 2. Both contain graphene. Graphene is widely used in different applications such as biological engineering, composite materials, energy storage, mentioned before optical electronics and many others. In a 2D state, graphene is almost transparent and very thin, about 1 atom thin to be exact, which makes it the lightest, but also the strongest material. It features some amazing abilities to conduct heat as well as electricity. That makes it perfect for lightweight products for cars, buildings, filtration devices and even airplanes. But graphene wasn’t always as easy to use, due to its extreme thinness. On solving that issue worked a team of researchers from MIT. They were able to create new graphene structures for 3D printing. Biomimicry allowed them to learn about the material and how to work with it. They used the 2D architecture of graphene in 3D structure to create spongy material that potentially can be a game changer in Additive Manufacturing.

Graphene is only one of the natural materials used for 3D printing, other potential candidates are glass, cellulose and chitin, check out more about them.

3D printing draws from nature

We need to learn to respect nature and the solutions it provides us with. Biomimicry allows us to observe, study and use what nature has created. It’s extremely useful when it comes to Additive Manufacturing as it can give us straight answers to building a lightweight and strong car or airplane parts. Biomimicry is also helpful with creating new materials for 3D printing, we can either give the materials special qualities or play with their structures to create different material architectures. Sometimes, nature reaches its limits and the roles change- it’s us who go further and use 3D printing to develop new solutions for our needs. Biomimicry has only begun to inspire us and there is definitely still a lot to discover.

Do you know any other amazing examples of nature influence on Additive Manufacturing? Or maybe this post has given you an answer for your problem? Share with us your opinion!

If you liked this post, don’t forget to sign up for our Newsletter, you don’t want to miss the next post!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook