Wondering how to 3D print faster? With light!

Posted By Kat Plewa on Mar 7, 2019 | 0 comments

Additive Manufacturing is the perfect solution for low-volume production. It doesn’t require expensive molds and gives you new design freedom to improve your products. It can produce highly complex, accurate and fully functional parts in a short amount of time. But what if the manufacturing process could be even faster?

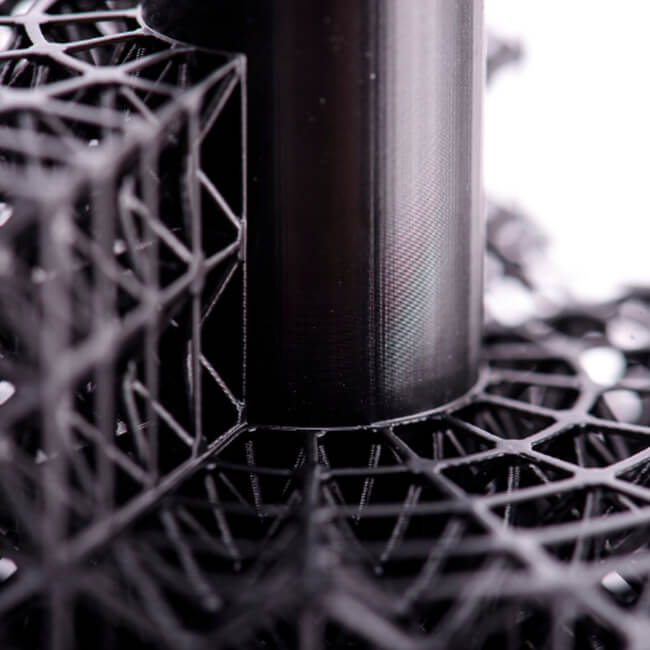

3D printing brings to you production design solutions such as lattices, which allows for the objects to be lightweight and create less material waste. Those factors are also more cost-effective. Not only that but Additive Manufacturing offers tens of materials to choose from, including plastic, metal, and resins. In this blog post, we will focus on the latter; how to 3D print faster with resin.

Light 3D printer from Michigan

Researchers from Michigan University claim they developed ‘’the true 3D printer’’. Timothy Scott, an assistant professor of chemical engineering commented ‘’Using conventional approaches, that’s not really attainable unless you have hundreds of machines’’. Scott decided to change that and with Mark Burns, a professor of chemical engineering and biomedical engineering started working on the project.

Researchers focused on resin 3D printing. Methods available consist of machines capable of producing highly accurate parts, layer by layer, out of thin resin by curing each layer with UV light. Question is, how to 3D print faster?

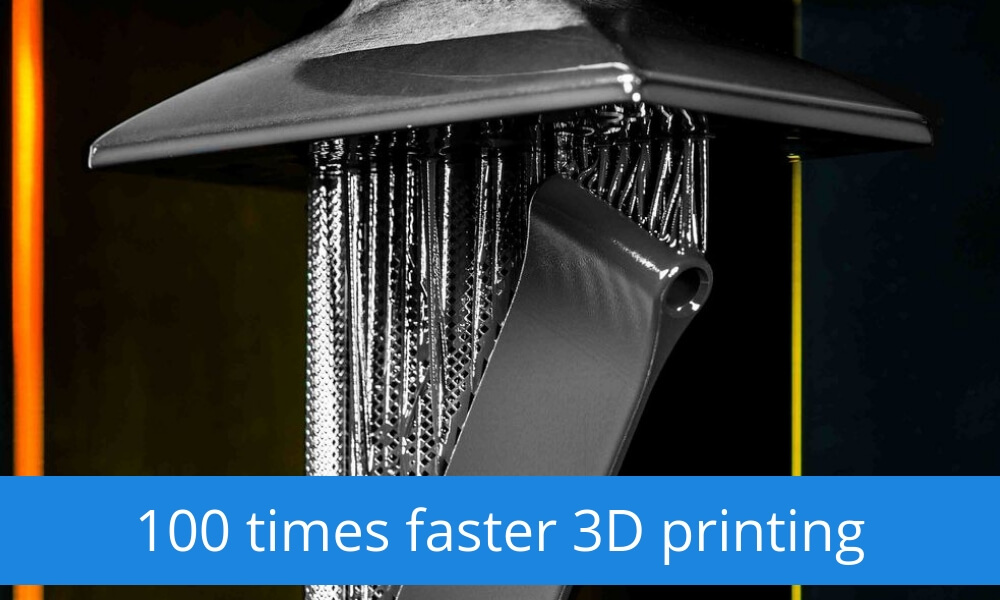

As a result of their work, a new 3D printer was built, as Burns described it ‘’It’s one of the first true 3D printers ever made’’. This technique hardens the liquid resin in a new, innovative way which allows for faster production thanks to two lights, one is solidifying the resin and the other one allows for the rest of it to stay liquid.

Researchers also addressed the issue of solidification-on-window. Right now, 3D printers harder a layer of resin, then oxygen is let through a window, it runs through the resin and stops the solidification process leaving a thin layer of liquid resin, which allows for pulling out a layer of the 3D printed object. Parts produced with these methods are rather fragile and are limited by a small size of the oxygen window and runny consistency of the resin.

Michigan development leads to the ability of manufacturing more durable parts. It allows for using thicker resins, possibly with additional strengthening ingredients. Also, the surface between layers is much better connected which positively affects the strength of the parts. Thanks to the two light solution, which substitutes the oxygen window, the objects are more durable, but can also achieve better printing quality and bigger size. Not to mention that the production is 100 times faster than traditional methods!

Learn how to 3D print faster right now

As you see, Additive Manufacturing is highly beneficial for production. It offers new materials and different technologies to best match your manufacturing requirements. Resin 3D printing has already reached giants like Adidas or Riddell, it is now time for you to start using this cutting edge technology to your benefits! Did you know that at Sculpteo we also offer resin 3D printing?

Start 3D printing faster with an online 3D printing service. You can choose from plastic, metal and resin technologies. It is as quick as uploading a 3D file to our website! If you have any questions about the process, don’t hesitate to contact us.

And don’t forget to sign up to our weekly Newsletter and follow us on Twitter for the latest 3D printing News!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook