What is hybrid manufacturing?

Posted By Lucie Gaget on Mar 11, 2019 | 0 comments

Have you ever heard about hybrid manufacturing technologies? We hear more and more about this new process, often seen as a little revolution. This process is using both subtractive and additive manufacturing. But why is this manufacturing process so interesting? That is what we are going to figure out in this blog post!

Hybrid manufacturing: What is it?

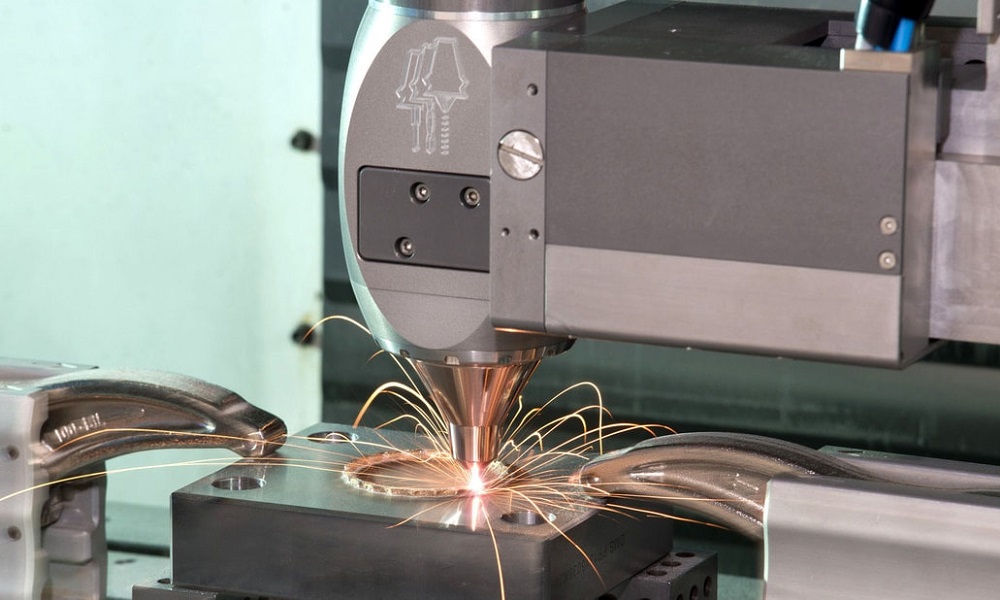

The idea of hybrid manufacturing is to combine 3D printing and milling technology. This process actually comes from the machinery itself, the two different processes are actually operating in the same hybrid machine!

For example, for metal, the powder is layered on in specific locations by a 3D printer, then melted and sintered by the laser. That is the process of additive manufacturing. But, with this new technique, at the same time, in the same machine, the piece is milled by blades that shape the newly placed metal into an end-product!

Metal 3D printing is already growing really fast, and it is not really surprising that some companies are already wanting to go further with this technology. Is hybrid manufacturing the future of metal 3D printing?

Why is this manufacturing process interesting?

Everything happens in one place

Hybrid manufacturing is not just using two manufacturing systems, using 3D printers and CNC machines. And this is precisely why it is so interesting, it’s using these two process at the same time, in a single machine. As everything just happens in one place, it could actually streamline the production process of many companies and improve the whole supply chain management.

Hybrid manufacturing could improve the manufacturing process by reducing the steps of production. The process would allow making the most of the advantages of both additive and subtractive manufacturing, save your time, and improve the quality of your products.

Reducing manufacturing waste?

Hybrid technologies could definitely be a game-changer for the manufacturing industry and eliminate the need for multistage manufacturing. It would also be a great way to reduce manufacturing waste, making this industry more eco-friendly, which certainly fits a bit better with the manufacturing methods of the future. Indeed, consumers are paying more and more attention to the environmental impacts of companies.

3D printing is already avoiding manufacturing waste, since with 3D printing, you only need to use the exact amount of material needed to create your project!

Hybrid manufacturing technologies are already promising!

Thanks to 3D printing and 3D printing services, companies already have the possibility to speed up their prototyping and production process, by reducing assembly time, manufacturing small batches at a lower price than with traditional manufacturing technique, etc. Hybrid manufacturing is still pretty new, but by combining the advantages of two manufacturing systems, this technique appears to be quite promising. Using the strength of these technologies could offer the possibility of creating better products.

It is still a bit early to say if this technique is totally worth it. We will certainly have to wait a few years before this method can be used for mass production, for example.

What do you think about hybrid manufacturing technologies? Share your point of view in the comments!

If you want to use 3D printing to develop your project, upload your 3D model right now on our online 3D printing service, get an instant quote and receive your parts in a few days only.

Subscribe to our weekly newsletter to get all the latest info about 3D printing innovations and applications.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook