What is laser engraving and how can you use it?

Posted By Kat Plewa on Jun 19, 2019 | 0 comments

Laser engraving can be a great asset to your production. From manufacturing purposes to tag parts with logos and numbers, to marketing and promotional applications, this technology can highly improve your production and brand image. But to start benefiting from it, you should understand how does laser engraving work and what design guidelines you need to follow to successfully start using it.

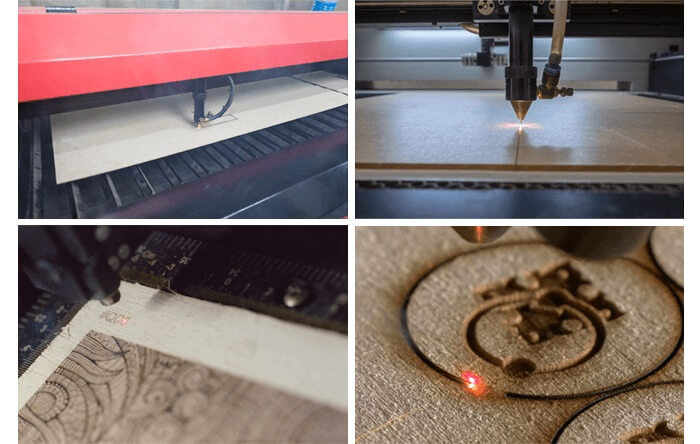

Laser engraving technology: how does it work?

Laser engraving is based on a laser beam streamed into a surface. First, you need a file, which is sent from the computer to the machine’s controller. The controller then positions the laser beam and burns or evaporates the surface according to the image.

There are two types of laser engraving: line engraving and surface engraving. The first one uses vector images to follow with lines or paths. Surface engraving works with an image to produce photos or to give designs 3D-like impressions.

What are the advantages of laser engraving?

This technology is particularly beneficial for rapid manufacturing. The process is very fast and quite reliable. It is especially effective where the time of production matters. This technique speeds the production process. You can now engrave important production information onto your mechanical parts, which will be permanent and imperishable engraving.

Laser engraving can work with numerous materials, from wood to cardboard and plastics, which is where traditional methods can fail. Therefore, laser engraving can empower your production with new materials and gives you new design freedom.

Engraving materials

There are numerous materials to choose from with different colors and thicknesses. Choosing the right material is an important step, so we will now give you an overview of the materials.

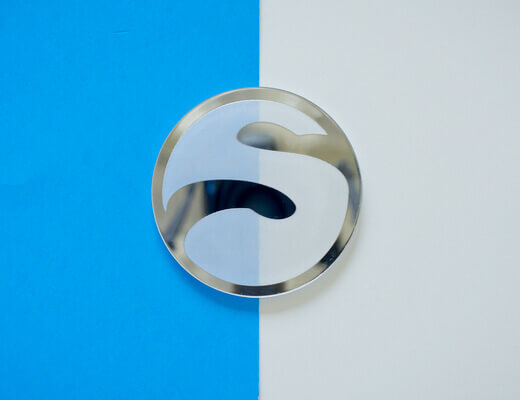

Acrylic

Acrylic is a plastic material, which is strong and quite resistant to scratches. It is also quite stable concerning tolerance and shrinkage. It handles laser operations very well, meaning your design will come out in good quality.

Moreover, this material can be exposed to other design methods such as gluing and painting and it’s waterproof and can be used in wet environments such as kitchens or bathrooms. Great applications of acrylic lay in different industries such as medical, lightning, or electronics.

For available thicknesses and colors, check out the acrylic page.

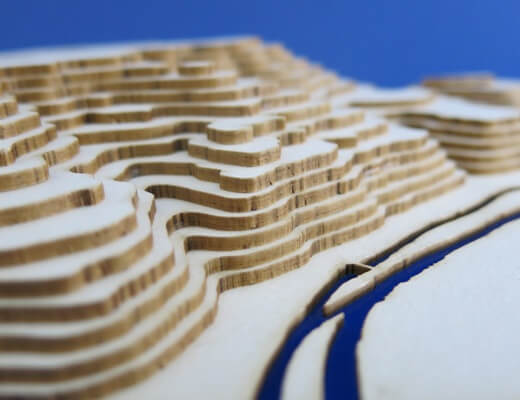

Plywood

This material is made of several sheets of wood glued together. Thanks to that, Plywood is widely used by builders, cabin makers, or industrial designers. The main characteristics of this material are mechanical resistance, flexibility, water resistance, lightness, and aesthetic look.

Plywood is a great material for finished products. As it’s made out of wood, it will enhance your designs with a unique, natural look. This material can also be worked with like real wood, you can glue it, it can be also screwed, sawed and nailed.

For available thicknesses and colors, check out the plywood page.

MDF

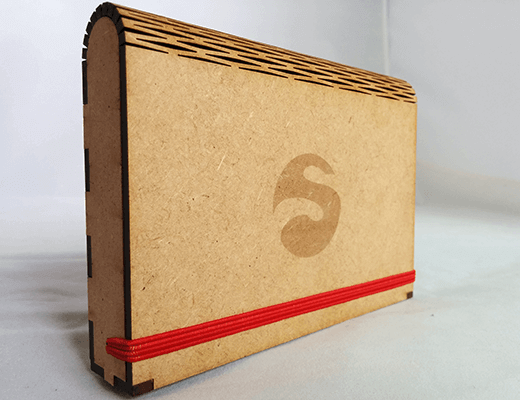

MDF, Medium- Density Fiberboard, is an engineering wood product. This material is produced from hardwood or softwood residuals broken down into wood fibers. The fibers are joined with wax and resin binder. With the application of high temperature and pressure, MDF panels are then formed.

MDF has a fine texture and natural light beige color. The main benefits of this material are the adjusting method which it can withstand, unlike solid wood. MDF can be painted, stained, dyed, fireproofed, waterproofed, molded, and even curved. It will also perform well while being exposed to sanding and planing as it doesn’t contain knots or rings.

For available thicknesses and colors, check out the plywood page.

Cardboard

Cardboard is produced by laminating flat, corrugated or embossed paper of different thicknesses. Cardboard can be very beneficial for your production as it is lightweight and has a competitive price.

As other laser engraving materials, it can be altered by cutting, gluing or folding. On top of all of that, Cardboard is also recyclable and biodegradable. It is widely believed cardboard is only used in packaging, but actually, it can also be great for prototyping or production of presentational models in the architecture field.

For available thicknesses and colors, check out the cardboard page.

POM

Polyoxymethylene, POM, is an engineering thermoplastic, it’s also otherwise known as Acetal or Delrin. This material is especially popular thanks to excellent mechanical properties, strong resistance, and great dimensional stability. It has a smooth, glass-like surface.

This material was designed keeping in mind especially internal technical parts. It’s lightweight, durable and robust, but also weatherproof, waterproof and solvent resistant. It performs well against cracking, making it a great candidate for industrial tooling, spare parts, gears, hinges or locks.

For available thicknesses and colors, check out the POM page.

Design guidelines

There are especially important rules you should follow when it comes to laser engraving. A very popular aspect of laser engraving is engraving text. When the text is sent to the controller, the machine automatically adds a border around the letters, therefore it is important for you to remember:

- Assure the letters have proper spacing

- Minimum size of text is 2 mm

- Narrow fonts are preferred

Laser cutting

A great asset to laser engraving is Laser Cutting. The process is similar to laser engraving, but with laser technology, the laser cuts through the material in the shape of your object. It is also fast and used on the same materials as laser engraving. The laser beam is very precise allowing for a rapid production at an affordable price. You can learn about the benefits of Laser Cutting with our blog post.

Did you know that you can actually combine laser engraving, laser cutting and… 3D printing? That’s the ultimate project of innovation! Check out our lightweight drone produced with those technologies!

How to start laser engraving?

We hope that this article makes more clear for you how laser engraving works. You now know that and also what materials you can choose from. It all starts with a file. If you already have it, simply upload it to your online laser cutting and engraving service! It’s that simple. However, if you don’t have a file, you can start by learning more about the best 2D software for laser projects or contacting our sales department.

Did you enjoy this article? Don’t forget to subscribe to our Newsletter!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook