Comparison between 3D printing and traditional manufacturing processes for plastics

Posted By Lucie Gaget on Jul 16, 2019 | 0 comments

Initially created as a method for rapid prototyping, 3D printing, which is also referred to as Additive Manufacturing, has grown into a true manufacturing process. 3D printing is giving engineers and companies the ability to both prototype and manufacture end-use products and it offers significant advantages over traditional manufacturing processes. These advantages include enabling mass customization, increasing design freedom, allowing for the reduction of assembly, and can serve as a cost-effective low volume production process.

This page will help you to understand the difference between 3D printing techniques and other manufacturing methods to help you decide which process is best for you. The page has been split into the following categories:

- 3D Printing and Traditional Manufacturing Methods: overview

- Selecting the Right Process

- Find the Manufacturing Process that suits you best

3D Printing and Traditional Manufacturing Methods: Overview

3D Printing Methods

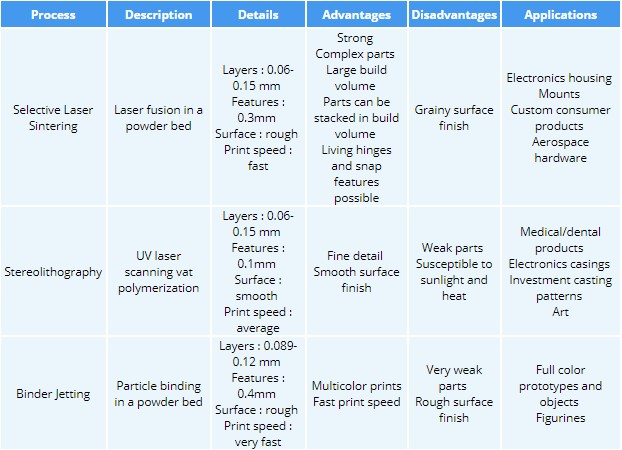

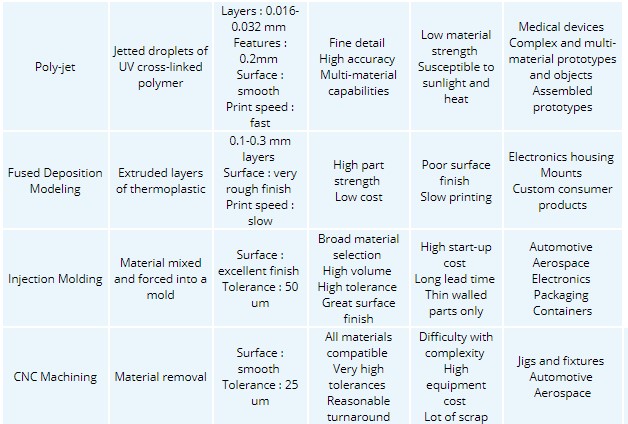

There are different 3D printing processes: Selective Laser Sintering (SLS), Binder Jetting, Stereolithography (SLA), Poly-Jet, Fused Deposition Modelling/Fused Filament Fabrication (FDM/FFF), etc.

To know more about the different 3D printing methods, you can refer to our 3D Printing Processes page.

Traditional Manufacturing Methods

There are four main families of standard manufacturing processes: injection molding, machining, forming, and joining. Similar to 3D printing, each manufacturing process has advantages and limitations. For more information, click on the processes summarized below.

Manufacturing Process Comparison chart

The above information is non-contractual, these are typical specifications for process selection purposes. Actual specifications depend on the machine, machine manufacturer, and material selection. It is your responsibility to ensure that the process you choose is adapted to your product.

Selecting the Right Process

To aid in the selection of a manufacturing process that best suits the needs of an application, it is important to first identify your requirements. There are several important questions you must ask yourself when deciding on the appropriate process.

Quantity: how large is the production run?

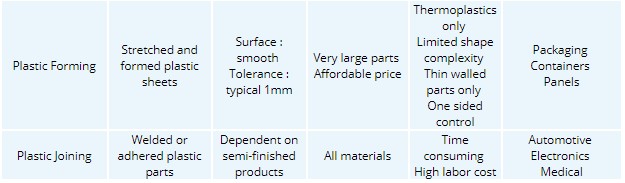

Traditional manufacturing processes like forming and injection molding are more suitable for large scale manufacture, whereas 3D printing may be more economical for small volumes. The chart below compares the estimated cost per unit of a GoPro handle when manufactured through injection molding (Quickparts) compared to Selective Laser Sintering (Sculpteo). In this case, 3D printing remains an economically valid option for the first 486 units.

Lead time: how soon do you need your parts?

The traditional manufacturing technologies require molds to be manufactured and factories to be ramped up to speed. As a result, it can take upwards of 15-60 days (and sometimes more) to have the first part in hand. For 3D printing, the part can be printed on demand and shipped without any ramp-up or tooling, resulting in a lead time as short as 2 or 3 days. In the case of the Go Pro handle, Quickparts quotes a lead time of 15 business days for any volume from 25-1000 units, whereas Sculpteo estimates that 25 units with a lead time of 3 days and 1000 units with a lead time of 7 days.

Shape/Complexity: what is your item shape?

For high complexity parts, fully assembled components or parts that need to be customized, using a Professional 3D printer is the best choice. Indeed, the price of such items would be very high and sometimes they would just be not feasible using traditional manufacturing technologies such as molding, machining or forming.

Material selection: what material do you need?

Traditional manufacturing options like injection molding and forming can offer a high material selection. When it comes to 3D printing, material selection is much sparser. FDM is limited to extrudable thermoplastics, SLS requires thermoplastic powder that is machine-specific, and SLA and Poly-jet applications are limited to photo-curable acylate and epoxy-based resins. To learn more about 3D printing materials proposed by Sculpteo, you can refer to our Materials pages.

Technical considerations

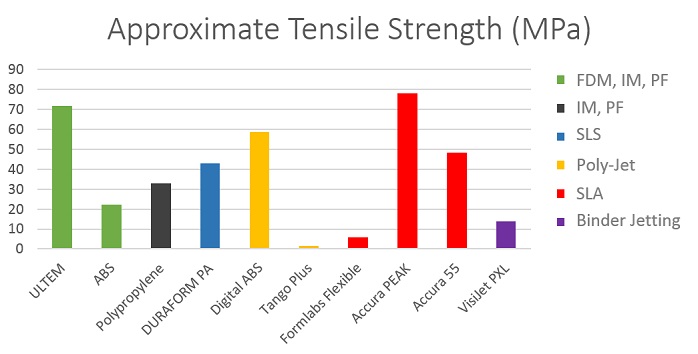

As the 3D printing technology matures, a greater variety of materials with varying characteristics are being introduced. The chart below introduces a variety of materials and their comparative tensile strength. The legend on the right identifies which technologies are capable of processing that material.

As the chart shows, thermoplastics such as ULTEM and ABS can be processed by FDM/FFF printing as well as injection molding and forming, demonstrating the ability of 3D printing to process high-strength engineering plastics. However, SLA and poly-jet require photo-curable resins, they cannot process these specific types of materials. To compensate, professional 3D printer manufacturers’ have developed materials to replicate the performance of certain engineering plastics (like Digital ABS and Accura PEAK) and introduce materials exhibit elastomeric properties (such as the Tango Plus and Formlab’s Flexible resins, also represented in the chart above.) However, it’s important to remember that as these resins are photo-sensitive, they tend to be susceptible to sunlight in heat.

3D printing is an additive layer process, which means that surface finish constrained based on the thickness of each added layer. Referring to the Manufacturing Process Reference Chart above, layers can range between 0.06mm to 0.3mm depending on the process, causing the surface to feel rough or “ribbed”, particularly on curved surfaces. High-quality 3D printers tend to print thinner layers than desktop-grade printers, resulting in a much better surface finish. Processes like injection molding and plastic forming are much smoother and can produce desired surface textures as well.

Find the Manufacturing Process that suits you best

For low volume manufacturing, high complexity parts, fully assembled components, parts that need to be customized, or that you simply need your part FAST, using a Professional 3D printer is the best choice. However, if material properties and surface finish are of critical importance, your complexity is low, and your manufacturing volume is low, then CNC machining may be a better option. For high volume manufacturing of relatively simple components, set your aim for a process like injection molding or forming. Still confused? For help selecting the correct process for your application, check out the selection tool below.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook