Revolutionary development in 3D printing heart valves!

Posted By Kat Plewa on Sep 3, 2019 | 0 comments

Additive Manufacturing has been saving lives with some unbelievable solutions. 3D printing brings into the medical world new materials and new production methods and lets doctors help patients in ways impossible before. Now, researchers from Carnegie Mellon University are bringing a new game-changer into the medical industry. What is the project about and how it will influence the future of medicine? Let’s find out!

What is the issue?

To understand the importance of this development, we should start by addressing the problems which scientists have been struggling with. 3D bioprinting is not unheard of. It definitely improves medicine with recent developments such as the 3D printed lung or even 3D printing tissue in space.

However, 3D bioprinting is still facing some challenges. The biggest one is keeping the material stable during the printing process. The material is soft and needs to be supported in order to obtain the necessary resolution for producing highly complex 3D printed structures. It is also crucial for achieving the desired properties of the 3D printed tissue.

What is the solution?

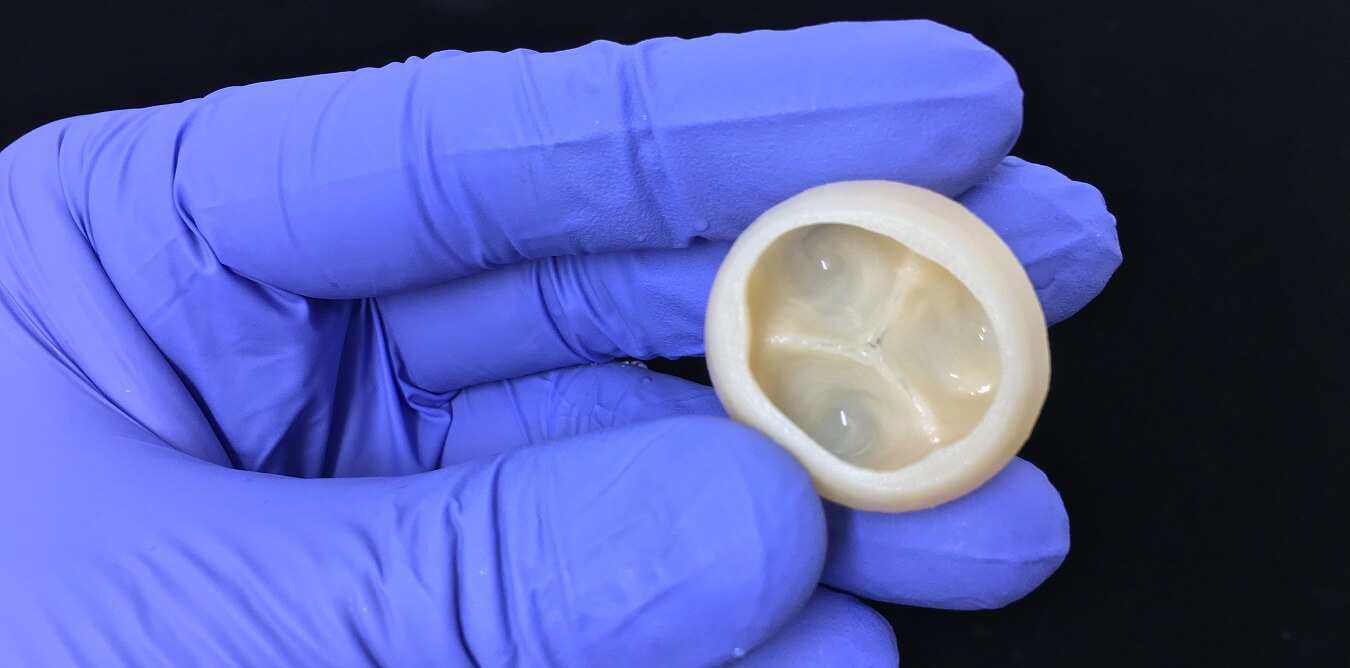

The scientists from Carnegie Mellon University advanced a method of 3D printing with collagen. The technology is called FRESH: Freeform Reversible Embedding of Suspended Hydrogels. It allows producing very complicated structures to resemble components of the human heart. In this particular case, we’re talking about heart valves and small blood vessels.

https://3dprintingindustry.com/news/carnegie-mellon-advances-fresh-3d-bioprinting-to-rebuild-the-heart-159473/

FRESH technology was awarded US patent and got licensed to FluidForm. Adam Feinberg, co-founder of FluidForm and chief technology officer commented on this development: “We now have the ability to build constructs that recapitulate key structural, mechanical and biological properties of native tissues. There are still many challenges to overcome to get us to bioengineered 3D organs, but this research represents a major step forward.”

FRESH technology allows 3D printing scaffoldings with collagen by supporting it with gel. However, the 3D printed form would often sag when the layers were too high.

Researchers from FluidForm found the solution by adapting the pH levels of collagen. Thanks to Additive Manufacturing they can control rapid pH changes for the collagen to self-assembly.

Why 3D printing?

The biggest advantage of using 3D technologies, especially in the medical sector, is the possibility o produce personalized models. It is crucial for organs to match the patients and 3D printing actually gives doctors a possibility to even produce a replica of the patient’s organ.

In fact, the researchers used human MRI images to create complex structures that were customized for the patient. Thanks to 3D printing they were able to produce smaller cardiac ventricles with human cardiomyocytes and they performed synchronized contractions!

Of course, there are still obstacles to overcome, but this is already a huge step towards 3D printing organs. This research proves that collagen and other soft biomaterials can be used in Additive Manufacturing to successfully reproduce human organs and tissues.

What is next?

FRESH technology proves how much potential lays in 3D printing. It is already changing the face of medicine, and it provides the doctors with truly unbelievable solutions to save millions of lives. Now, FluidForm is planning to commercialize the FRESH technology, hopefully, that day will come soon. 3D printing heart is just a step away.

Do you have a 3D printing project? 3D printing with an online 3D printing service! And if you have any questions, don’t hesitate to contact us.

For more 3D printing news, subscribe to our Newsletter and follow us on Facebook!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook