3D printed gears: pro design tips and software advice

Posted By Kat Plewa on Nov 20, 2019 | 0 comments

3D printing has a lot of great applications for mechanical engineering projects. But did you know that you can produce strong and fully-functional gears thanks to Additive Manufacturing? What advantages do 3D printer gears have? Today we will, give you pro tips on the design process, discuss the 3D printing materials, and also advise you on the best software to use. Are you ready? Gear up!

Design Tips: what to watch out for when 3D printing gears

-

Number of teeth

When designing gears you have to think of their ratio. The recommended ratio for 3D printed gears is from 0.2 to 5. It affects the number of teeth on your gear. If you choose 2:1, you can create various numbers of teeth: 30 and 60, 15 and 30 or 8 and 16… there are plenty of combinations.

The number of your teeth also depends on the pressure angle. We will talk about the pressure angle in the next section. Recommended for 20-degree pressure angle number of teeth is minimum 13. For a 25-degree angle, the number of teeth lowers to a minimum of 9. Why those numbers? Because if you design fewer teeth, they will require an undercut and that can be challenging to 3D print.

Extra tip: when it comes to speaking of exact numbers, an interesting solution is to design an extra tooth. For example, 15 and 31. Why? Because with 15 and 30, the teeth always meet in the same way and it will wear them out quicker. With 15 and 31 teeth, the signs of use will be evenly spread.

-

Strength of your gear

If you have fewer teeth, generally, your gear will be stronger. Also, your teeth will be bigger which also makes the whole gear more robust. Consider how big the gears should be for your project.

Additionally, tiny teeth are weaker, they can break easier, but also the gear might skip them and not work accurately. Tiny teeth are also much harder to produce. Larger teeth will be produced with better precision. You should really consider how many teeth your gear needs.

To achieve more robust teeth, basically, double the width means double strength. In terms of thickness, it is recommended to design it at least 3 to 5 times the circular pitch of the gear. Keeping those values in mind should help you to produce strong 3D printed gear.

-

Precision

The precision of your gear will depend on the number of teeth and strength. However, don’t design gears with just a few teeth. It is important to find balance. More teeth also means a smoother workflow of the rotary motion and therefore affects the whole mechanism. So think about the purpose of your project and how precise the gears have to be.

For additional accuracy of the mechanism, you can consider adding an extra gear. It will provide more stability to your project and let your mechanism run evenly.

What about the pressure angle?

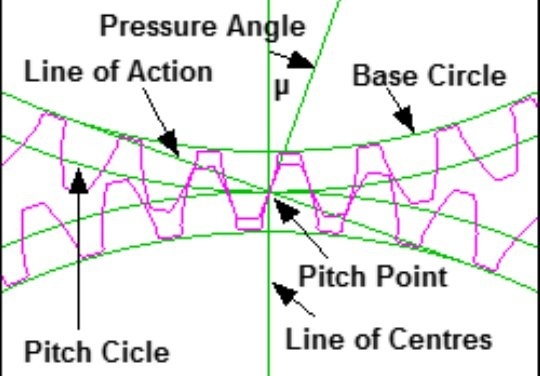

The pressure angle, also called the angle of obliquity, refers to the angle between the tooth face and the gear wheel tangent. The larger the angle, the more triangular the teeth. Triangular teeth are easier to 3D print and they are stronger, but on the other hand, they are less efficient at transferring torque and more noisy.

In terms of 3D printing gears, for a palm-sized gear, a 25-degree pressure angle is advised. It will provide stiffness and stability to the gear.

What software is the best to design 3D printed gears?

When it comes to 3D modeling, you have the ability to design highly customized gears that will fit exactly your needs. And with Additive Manufacturing you can achieve precision at the best quality. Is it hard to design gears for 3D printing?

Not at all! There are actually some really useful online tools dedicated just to 3D modeling gears. One of them is called Gear Generator and thanks to its user-friendly interface, you can quickly design your own mechanisms. Other online software is Rush Gear and Hessmer Spur Gear Builder. Moreover, you can 3D model them with one of the Top 15 mechanical engineering software.

What material to choose for 3D printed gears?

Among the main properties you should consider for 3D printed gears, are stiffness and durability. Those are characteristics of Nylon. Nylon PA12 is a great plastic material for mechanical projects. It has low friction coefficiency, high melting point and inter-layer adhesion. An important thing to mention is that Nylon is not waterproof.

Another material interesting for 3D printed gears are metals. Additive Manufacturing offers a wide range of options:

Aluminium AlSi7Mg0.6– 3D printing powder which is durable and lightweight

Titanium Al4-V– fine metal powder which stands out for its low toxicity and high melting point

Stainless Steel 316 and 316L– this material will provide you with great accuracy and strong resistance to corrosion

Ultrafuse 316– this one of a kind 3D printing filament build of 90% stainless steel and 10% polymer binder

Should you 3D print gears?

As you can see, Additive Manufacturing offers a lot of advantages. You can highly customize your gears, adjust their shape, pick the right technology and material to 3D print them with. There are also essential values for you to keep in mind, such as the number and shape of teeth, or the pressure angle. Hopefully, you found all of our advice useful.

Did you know that you don’t have to own a 3D printer in order to produce your gears? With an online 3D printing service like Sculpteo, all you have to do is to upload your file and get your professional-grade gears delivered straight to your door. And in case of any questions, feel free to contact our 3D printing experts.

Don’t forget to sign up for our Newsletter and follow us on Facebook!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook